Well, allrighty then, the falsus nomen Flying Pig Project

How to make 650 lbs fly quicker, faster and higher.

All hot rodding items on the table. First, let's design the project (OMG, an engineering plan on which to stage a project). First, what target power level are you aiming for? What kind of Sport/Tour driving experience will the upgraded engine provide? Will the torque and HP come from more top end RPM or lower RPM breathing? What goals are there for fundamentals like piston size, rod stroke, combustion chamber volume & shape, valve size, compression ratio and cam profile? On the secondary items, how will the fuel mapping take place and how will you get an aftermarket ignition controller installed? Once all this is settled, it's time to look at air intake, intake runner length, header shape, length and exhaust system. While thinking things over, it's also time to dig out the plastigauge, micrometer and scales for a little blueprinting and balancing.

On the other hand, I'm pretty sure that an inexperienced person could do a fair amount of harm if they try to do shaping beyond just polishing. I have had the cylinder head off my '04 FJR, I've looked at the intake runners and cylinder head pockets (hardly a pocket) and decided that the 2 - 5 hp wouldn't be worth the work.

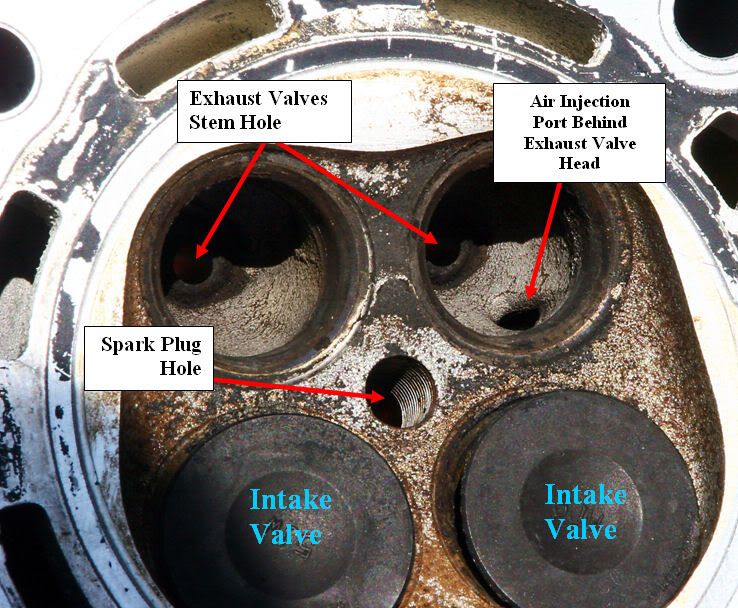

Look at all that opportunity to polish! Man, just makes ya want to break out the pneumatic hone... It sure makes a feller want to smooth, blend and knife edge ****.

![fjackets Real Lambskin Leather Biker Jacket — Quilted Cafe Racer Zip Up Moto Leather Jackets For Men | [1100085] Johnson Brown, XL](https://m.media-amazon.com/images/I/41I7Pm1f+vL._SL500_.jpg)