hey guys. i have an 04 with 45K on it and i am trying to install a pair of FIAMM highway blasters and would like to install a barrier strip while I am at it. i already have wired a garmin 2720 to the battery.

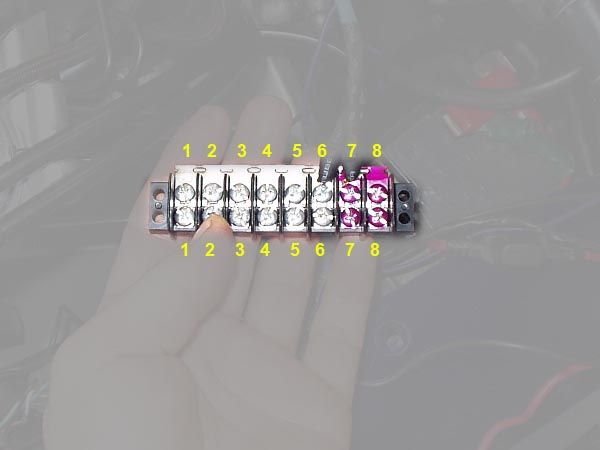

i saw a couple of threads on installation and it seems pretty straight forward, but I just cant figure where the barrier strip and the jumper goes in the circuitry. where does the barrier strip go in the circuitry and how do you wire farkles to the strip???

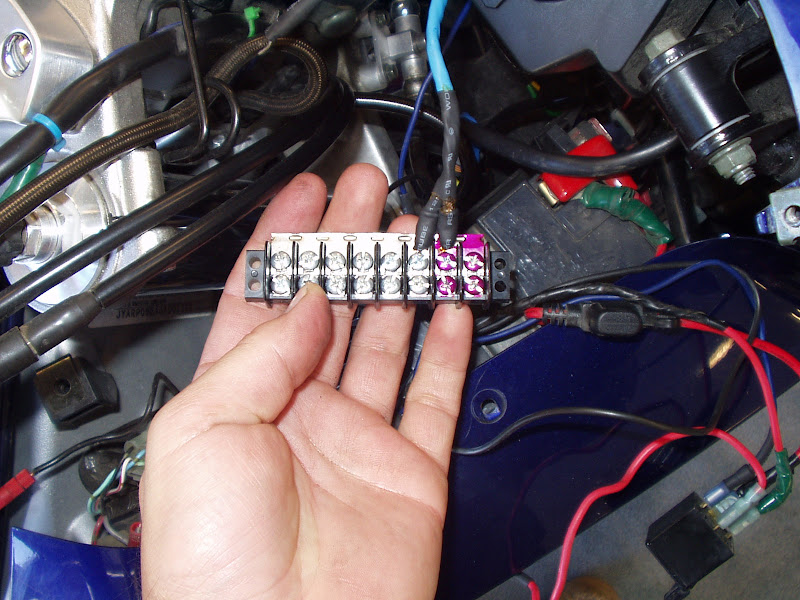

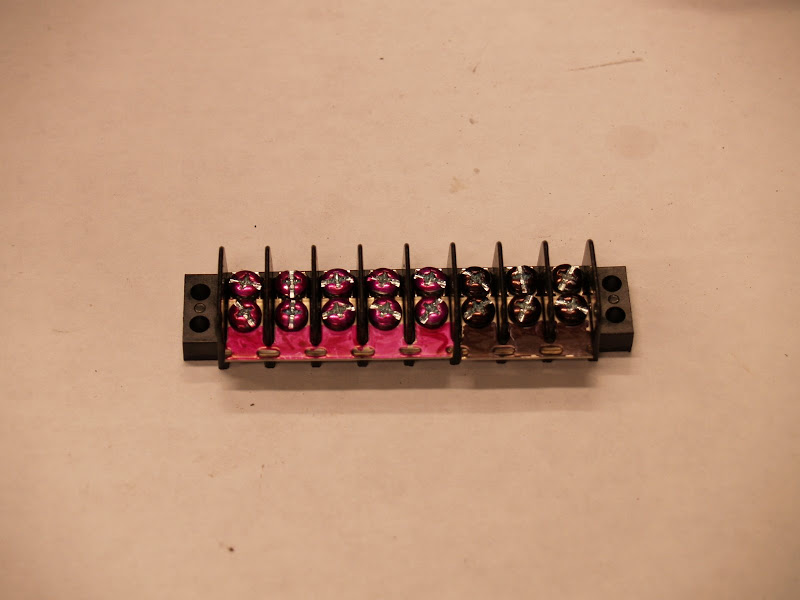

i plan to use a dual row barrier strip. what's positive and what's negative on the strip???? and where does the jumpers come in??? can somebody post a diagram including:

the battery, barrier strip, relay, farkles.

somebody shed some light. thanks.

i saw a couple of threads on installation and it seems pretty straight forward, but I just cant figure where the barrier strip and the jumper goes in the circuitry. where does the barrier strip go in the circuitry and how do you wire farkles to the strip???

i plan to use a dual row barrier strip. what's positive and what's negative on the strip???? and where does the jumpers come in??? can somebody post a diagram including:

the battery, barrier strip, relay, farkles.

somebody shed some light. thanks.