OK, well since there seems to be some genuine interest in this, I'll expose you all to more of my regular hot air (how do you think we got those balloons up in Vermont?)

First off, Georgia Roller owns a 1st gen (2005) so his is the same as mine.

Also, it isn't the lower bushing that you'd want to delete. You would leave out the middle one. The one on the bottom is absolutely required as it is the only one that is captive on the inner tube. and slides up and down in the outer tube. The upper bushing is pressed into the top of the outer tube, and the inner tube slides through it's inside surface, so as the suspension articulates the two bushings slide towards (and away from ) each other. The middle bushing on 2nd gens is redundant to the upper bushing. It too is pressed into the outer leg.

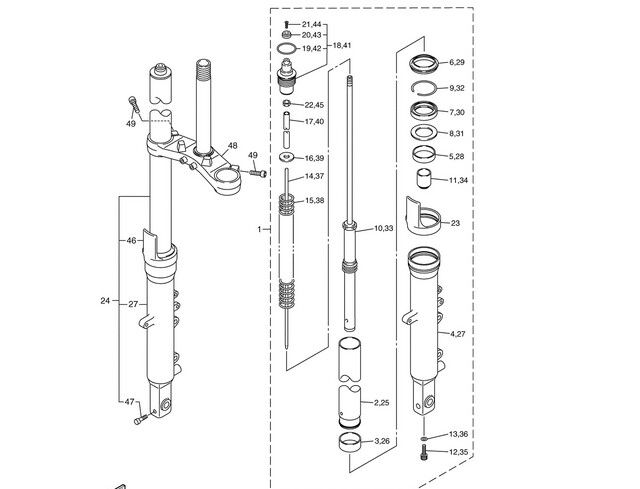

Here's a look at the 1st gen parts drawing:

The lower bushing is #3, 26 and you can see the lip on the bottom of the bottom of the inner fork tube that captivates that bushing after it is slipped on. The upper bushing is #5, 28 and that is just pressed into the top of the outer fork leg, then the washer, oil seal, circlip and dust seal go on top of that.

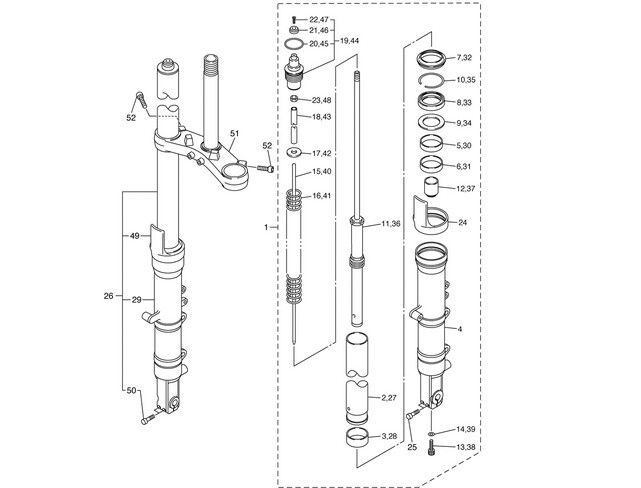

Now here is the 2nd gen parts diagram:

You'll notice that the upper and lower bushings are still there (3,29 and 5,30) but now there is an additional bushing #6,31, which is of a slightly smaller diameter than 5,30. It is slid down further into the outter fork leg and seat on a lip about half way down the outer leg's length. THat would be the one to skip.

Now here's the part I deleted earlier about why I would do that:

The inner fork tube is a long, relatively thin steel tube and (due to weight compromises) is actually somewhat flexible. Ideally it would not flex

at all under varying suspension loads, and that is where the upside down fork designs are better, the majority of their length being the thicker, larger diameter, and therefore stiffer alloy outer fork tube in that design, they will flex less.

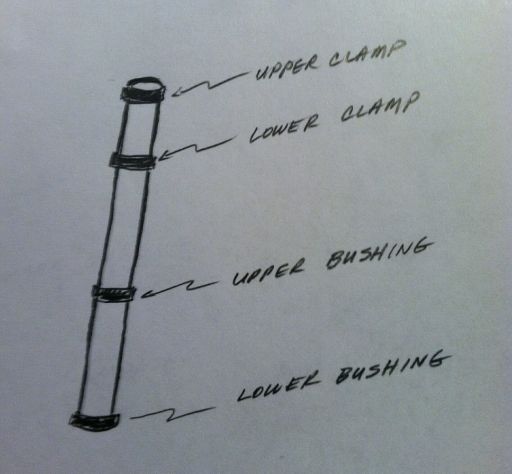

Regardless of whether you have two bushings or three in the FJR fork lower, the inner fork leg will flex over it's total length. It is supported by two triple clamps at the top and (at least) two contact points (bushings) at the bottom inside the lower. The lower (outer) fork leg does not flex. It is too thick and stiff. So what you end up with is a flexible inner pipe supported by 4 contact points. This is where I wish I had good computer graphics skills and could create some nice diagrams. Instead you get this

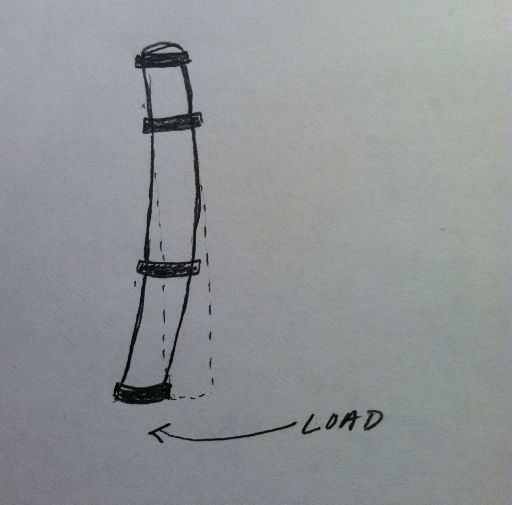

When there is a lateral load on the fork leg the inner fork legs will flex a little, not just in the part that you can see between the lower triple clamp and the top of lower fork leg, but

all the way along its length, even in between the two triple clamps and between the two bushings (greatly exaggerated):

In the second gen design, they put the third, middle bushing in the inflexible lower fork leg in an attempt to restrain this inner leg flexing, but that will really only limit the flex that occurs between the upper and lower bushings, not the rest of the fork's length. And as it does so, it causes greatly increased friction in all three of the bushings as the then curved fork leg tries to slide through the fixed bushings. The primary goal of the fork is to absorb road irregularities. Added friction is contrary to that goal.

Furthermore, no inner fork leg tube is 100% straight to begin with, nor are the bushing seats milled with absolute precision. Which means that even when the forks are not being "sprung" they will not be absolutely straight and true, which means that the third bushing will always be increasing the friction (aka stiction). This is why the second gen wears through the Teflon bushing surface in 10k miles and the first gens can go 50k miles or more and still have some of that Teflon wear layer left.

By eliminating the middle bushing you completely eliminate that effect. Since the lower fork rides on only two contact points it can follow the bent inner tube when flexed with no additional binding and no added friction. Will the inner fork tube be allowed to flex more in the section inside of the lower fork leg? Yes, but who cares? The flexing that is important is over the entire length of the leg, especially what happens between the triple clamps and the fork lowers, as that is what affects the wheel's attitude the most. Restricting the flex inside the lower leg is of little importance, IMO.

In the area of "FWIW", when (at least some of) the aftermarket suspension shops rebuild 2nd gen FJR forks, they also leave out the middle bushings for better suspension performance.

In the end, we are all free to do whatever we want to to our own bikes, based on whatever we are convinced is best. IOW YMMV.

But if I had a second gen FJR I'd ditch those third (middle) bushings the first time I had the forks apart