mcatrophy

Privileged to ride a 2018 FJR1300AS

To satisfy my curiosity, I decided to measure the current draw under various non-running conditions (how long will the battery hold up with the ignition on?), this on my 2014 FJR1300AS (it would be the AE in the USA, and has the ES suspension).

So, I hooked up a meter in series with the negative connection (without ever breaking the connection so no trips were lost), pointed my camera (mostly set to movie) at the meter, and did a few tests.

Firstly, the battery voltage after the bike had sat for over a day: 13.06V

(Click on image for larger view)

Ignition off: <0.01mA (<10uA)

Kill switch off (engine could run):

Turn ignition on, initial current 9.1A, dropping to ~ 4A after the fuel pump stops.

Turn off the ignition, kill switch set to On (fuel pumps won't run), now turn on the ignition:

~ 5.2A dropping to ~ 4A after a second or so.

Ignition off:

0.47A then down to 0.002A (the higher current is while it's saying "Goodbye" [how Japanese]).

And with the ignition switch in the "Park" position (mine is a '14 with the LED front side-lights):

~ 1.5A

Finally, because I have my heated vest controller/voltmeter, I measured its current:

128mA (varying a little with the display segments) down to 37mA as the display changes from bright to dim.

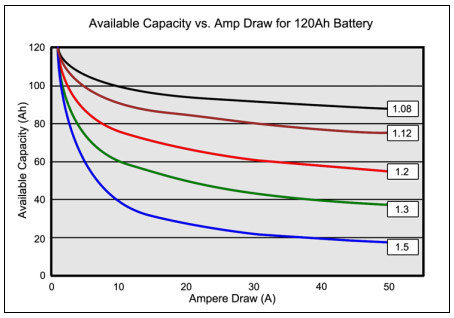

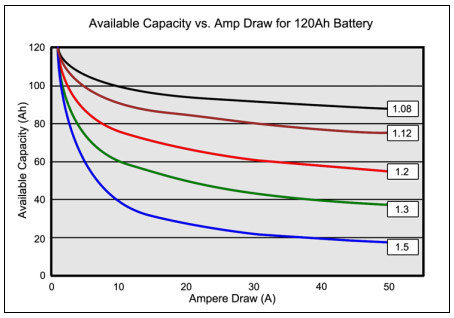

Just thought it might be of interest to see how long the battery might hold up for if the engine isn't running, my guesstimates* to half capacity:

Capacity Current Multiplier at current Time to half 12 4 0.57 00:51 12 1.5 0.87 03:28 12 13 0.45 00:12

(Reference: https://batteryuniversity.com/learn/article/calculating_the_battery_runtime).

So, I hooked up a meter in series with the negative connection (without ever breaking the connection so no trips were lost), pointed my camera (mostly set to movie) at the meter, and did a few tests.

Firstly, the battery voltage after the bike had sat for over a day: 13.06V

(Click on image for larger view)

Ignition off: <0.01mA (<10uA)

Kill switch off (engine could run):

Turn ignition on, initial current 9.1A, dropping to ~ 4A after the fuel pump stops.

Turn off the ignition, kill switch set to On (fuel pumps won't run), now turn on the ignition:

~ 5.2A dropping to ~ 4A after a second or so.

Ignition off:

0.47A then down to 0.002A (the higher current is while it's saying "Goodbye" [how Japanese]).

And with the ignition switch in the "Park" position (mine is a '14 with the LED front side-lights):

~ 1.5A

Finally, because I have my heated vest controller/voltmeter, I measured its current:

128mA (varying a little with the display segments) down to 37mA as the display changes from bright to dim.

Just thought it might be of interest to see how long the battery might hold up for if the engine isn't running, my guesstimates* to half capacity:

- Ignition left on (NO HEADLIGHTS), 4 amps, say 50 minutes;

- Parking lights left on, 1.5A, say 3:30 hours;

- With headlights: (4A plus say 2 x 4.5A = 13A) say 12 minutes.

Capacity Current Multiplier at current Time to half 12 4 0.57 00:51 12 1.5 0.87 03:28 12 13 0.45 00:12

(Reference: https://batteryuniversity.com/learn/article/calculating_the_battery_runtime).

Last edited by a moderator: