yamafitter

Reigning NERDS Granite Lane Gold Medalist

Yesterday I had my 06 AE strand me on the side of the road when I got a weird shift and a SH_51 code came up on the dash.

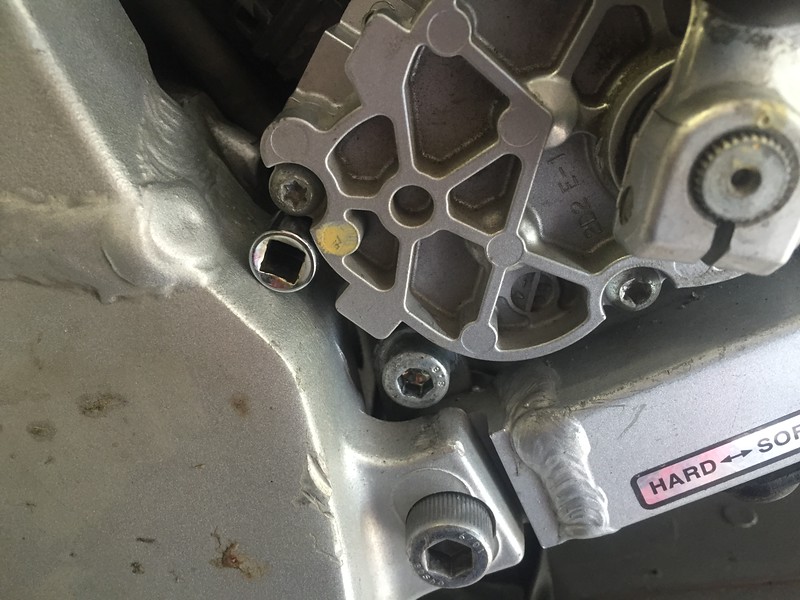

I was stuck in gear and the bike would not restart. Fortunately I was still in town but the bike was not going anywhere. I pulled the side panel off and noticed that the shift actuator was loose. I got the bike up on the centerstand and grabbed the shift rod and was able to get the bike into neutral so I could push it to a safer location.

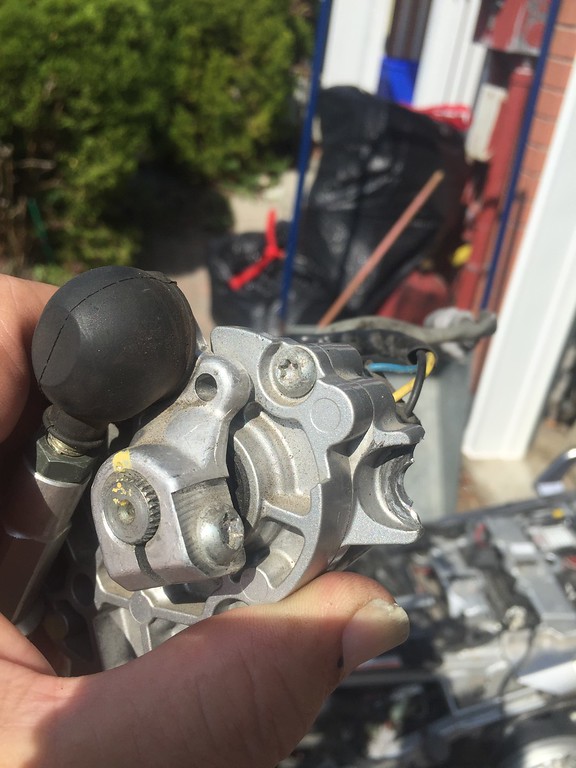

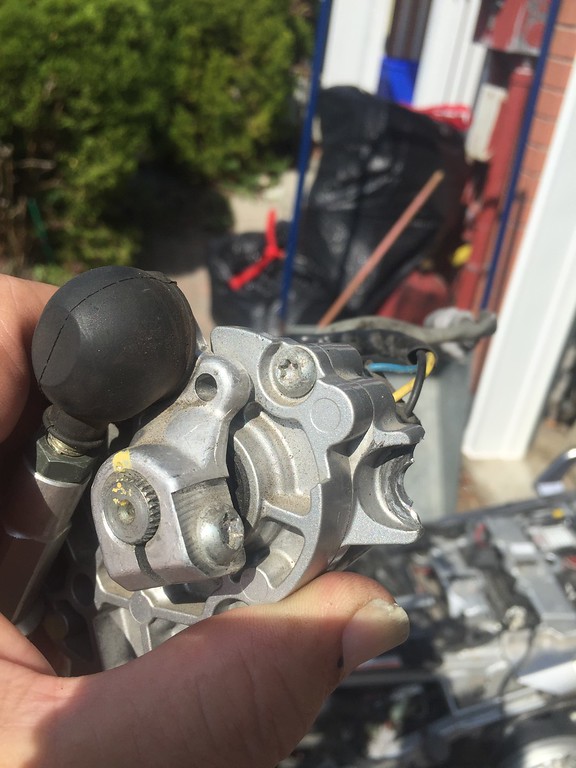

I had called for a tow truck but someone came along that I knew so I cancelled the tow truck and my friend gave me a ride home so I could get the trailer and go fetch the bike and bring it back home. Today I got into it and found this when I pulled the actuator out of the bike....

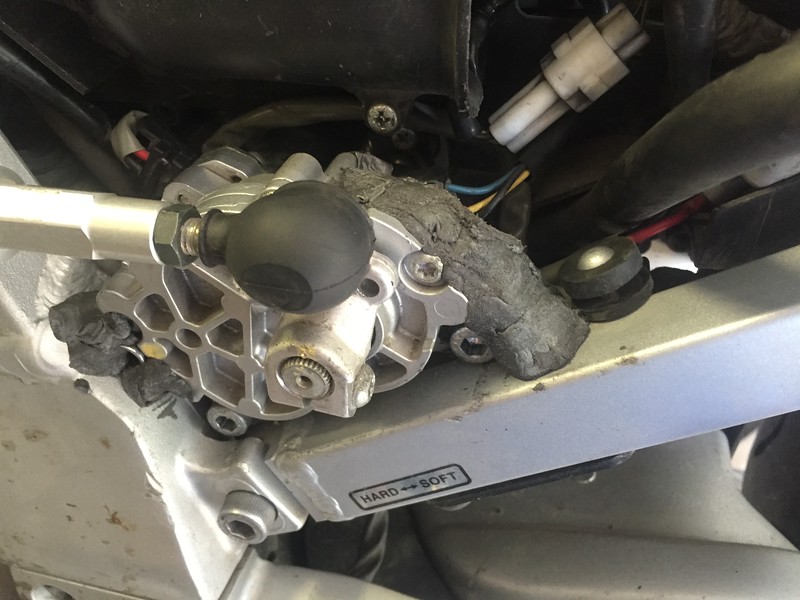

To replace the actuator is roughly $1400 and there are none in the warehouse in Canada anyways. I have both CFR and Red Lodge coming up so it was time to McGyver something. A quick run over to Canadian Tire and I came back with some Weld Bond and some 8mm washers....

I had the broken piece so I used the Weld Bond to reattach the broken piece and then I used more Weld Bond to sandwich the broken piece with two 8 mm washers. I gave it time to let everything setup and remounted the actuator. The captured nut on the front side was defective so I had to remove it and had a bad time of it getting an 8mm nylock nut up into position but I was finally able to get it and tightened everything up. The actuator is now very solidly mounted.

I checked the alignment hole to make sure the shift rod was in proper alignment and then boxed everything back up. Turned the key on and the shift error code cleared. Ran the bike through a couple of shifts while on the centerstand all all seems good.

With luck crisis averted. I'll take the bike for a short run on Monday to see how the patch holds up before trusting it on the run up to CFR.

I was stuck in gear and the bike would not restart. Fortunately I was still in town but the bike was not going anywhere. I pulled the side panel off and noticed that the shift actuator was loose. I got the bike up on the centerstand and grabbed the shift rod and was able to get the bike into neutral so I could push it to a safer location.

I had called for a tow truck but someone came along that I knew so I cancelled the tow truck and my friend gave me a ride home so I could get the trailer and go fetch the bike and bring it back home. Today I got into it and found this when I pulled the actuator out of the bike....

To replace the actuator is roughly $1400 and there are none in the warehouse in Canada anyways. I have both CFR and Red Lodge coming up so it was time to McGyver something. A quick run over to Canadian Tire and I came back with some Weld Bond and some 8mm washers....

I had the broken piece so I used the Weld Bond to reattach the broken piece and then I used more Weld Bond to sandwich the broken piece with two 8 mm washers. I gave it time to let everything setup and remounted the actuator. The captured nut on the front side was defective so I had to remove it and had a bad time of it getting an 8mm nylock nut up into position but I was finally able to get it and tightened everything up. The actuator is now very solidly mounted.

I checked the alignment hole to make sure the shift rod was in proper alignment and then boxed everything back up. Turned the key on and the shift error code cleared. Ran the bike through a couple of shifts while on the centerstand all all seems good.

With luck crisis averted. I'll take the bike for a short run on Monday to see how the patch holds up before trusting it on the run up to CFR.

Last edited by a moderator: