3dogs, good diagram and exactly what I was trying to say.....I think.....LOL

CM, thanks for bringing this up. I always like it when someone causes some new thought on something old....

We have used that type of ignition system on several automotive applications for many years. Very reliable, incredible ignition energy potential, etc.

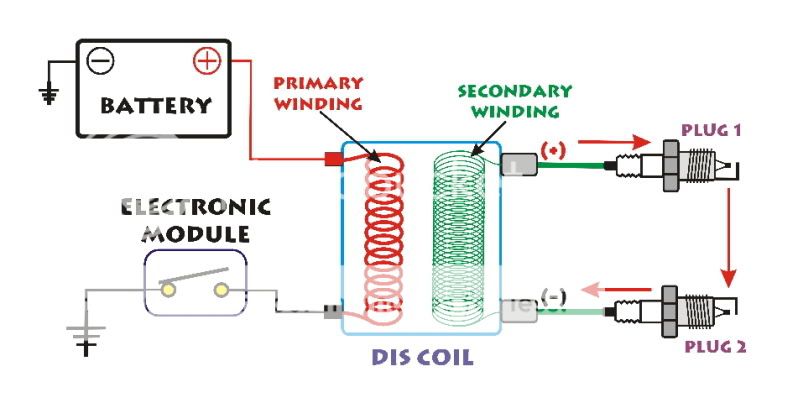

What threw me was the CM's question about opening one of the spark plug leads thus causing the other plug on that coil to go down as well. Along those lines, for some reason, I got into my head that the secondary windings had a ground connection in the middle of the coil. But, that didn't make any sense from past recollections and my gut level answer was exactly what 3dogs drew with the complete secondary coil feeding one plug lead + and the other plug lead - . If the secondary coil was not grounded in the middle and was an isolated coil winding only connected at the spark plugs to ground then how would one plug still work if the other were disconnected???

No one around here where I work seems to know why that other plug still will fire, though......LOL.

Indeed, our automotive (and I'm pretty sure all the motorcycle and other ignition coils like this) direct fire coils have an isolated secondary winding just like the diagram 3dogs drew.

From practical experience gained thru many diffferent trials (some deliberate and others not so....) I know that the "other" plug will still fire even if one plug is disconnected.

If one of the plugs fouls or the plug shorts to ground the answer is easy....that leg of the circuit is completed thru the ground or short and the other plug still works.

If one of the plug wires is off, that other plug still fires, though.

I have three possible explainations, based on discussions with co-workers, why....one is actually an observation and the others are theories that are yet to be proven.

First, as mentioned, those coils have tremendous ignition energy. The secondary voltage only goes as high as need be to jump the gap at the spark plug tip....or where-ever else there is a gap....like the plug wire off. My experience is that it is virtually impossible to "open" one leg of the circuit so as to disrupt the voltage path. The coil will simply generate enough voltage to jump whatever gap you create. Even pulling a plug wire off at the coil will cause the coil tower to arc to ground...almost 2 inches....and complete the circuit. Our coils like that can generate 50,000-60,000 volts in that situation I'm told(not continuous but temporarily before something melts.) That is plenty to jump most any practical gap that can be created on or around an engine. Even taking the plug wire off at the plug and dangling it into free space will cause the coil tower to arc past the boot and to ground at the coil so it just about impossible to really "open" one of the secondary circuit legs. This fits with my preconceived notions about those coils and fits from the experience I have had testing engines with those systems. So, practically speaking, I would say that the other plug still works because you cannot physically/realistically open the plug circuit on the other leg.

Secondly, some of the "experts" around here involved with the discussion so far think that if one of the legs of the secondary circuit is opened the voltage will go so high on the other plug that it will still start to ionize the gap of the plug thus initiating combustion even without a dedicated "spark" event. Possible, maybe, but not proven. I do know that the center electrode can get hot enough under some sitations (WOT, too hot of a spark plug) to initiate combustion without a "spark" and the giveaway is the ionization of the spark plug gap just before this pre-ignition event occurs. So, there is some basis for believing in the gap ionization with very high voltage idea. But not proven.

Third, some of the "experts" I work with are in the camp that think that the other plug will indeed NOT fire if the secondary voltage leg is interupted completely. They also think that they have never seen this happen (like me). The answer is is the first one given, that it is practically speaking impossible to open and isolate the secondary voltage circuit well enough to prevent an arc from occuring (given the basic OEM spark pllug cable/coil tower hardware on the machine). BUT, if you COULD isolate and interrupt the secondary spark plug lead on one leg then the other let wouldn't fire.

SOOO......more to follow as more experts I know weigh in. This is one of those questions that may have more than one correct answer. The practical answer is that the other plug keeps firing. Why is a bit of a mystery maybe. The theoretical but unobtainable answer is that the other plug will not fire....but that never happens. See the previous answer.

Personally, I think that the other plug will not fire if the secondary circuit could be interrupted completely and competely isolated from ground.....but I think you would play hell trying to accomplish this and you will get such a shock in the process.

Good thought starter. Never seen so many puzzled looks for a simple question. LOL.