After washing the pad has acted weird, with the power on light staying on. But not always, depends on if the pad gets sprayed down good. I have the Skyway mount and I sealed it with RTV on the back of the pad.

To answer the question though, no, I had not recently washed the bike nor ran through any rain. Clear dry day.

All connections are soldered except for the power connection to the power distribution block.

Inlaw1,

The RTV on the back of the pad is a good idea -

IF the RTV used is NOT AGRESSIVE TOWARDS COPPER!!. Read the fine print on the tube, or go the manufacturers website and find the MSDS on the product. Most RTV sealants are

muy no bueno against copper. I would suggest that you open the switch up (if it's not sealed by the RTV) and examine the copper traces on the PCB.

The switch side (the side under the rubber buttons) also needs to be sealed - you may have water entering between the face cover and the flexible rubber 'on off set res' and causing shorts on the pad. I would imagine this would evaporate rather slowly, and might add to corrosion. The problem you describe leads me to suggest that you may have corroded contacts on the control pad.

As the saying goes - 'This posting is worthless without pics" so - I just ran out to the garage, grabbed a brandy new control pad that I just happened to have sitting on my work bench, and sealed it - took about 5 minutes or so.

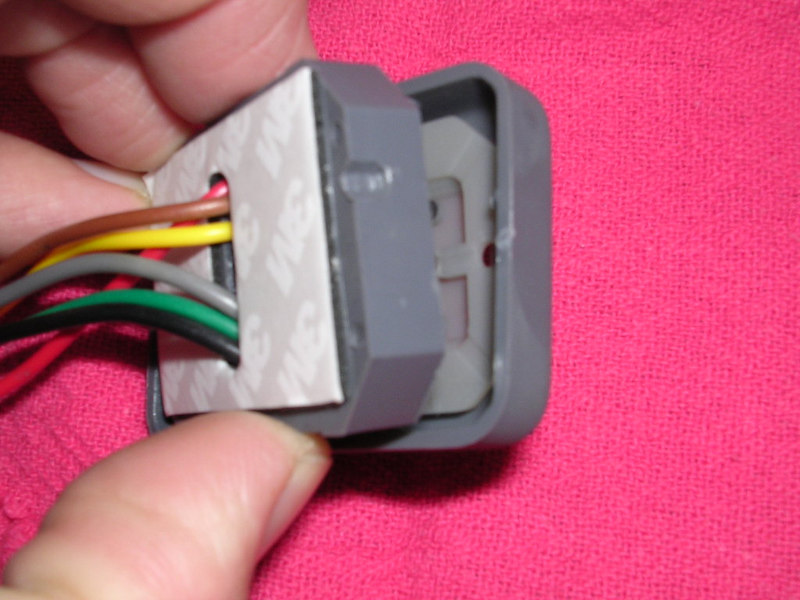

We all know this item, don't we?

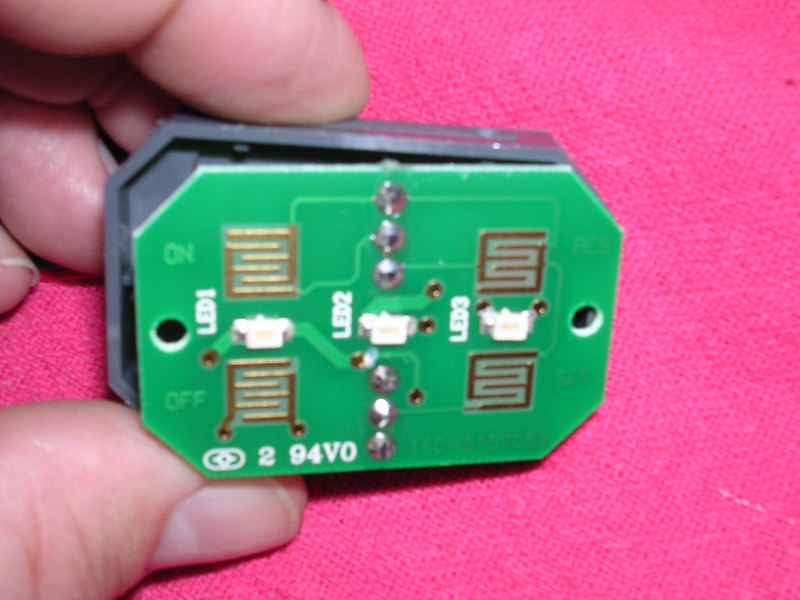

Inside of the rubber pad - those little black 'pucks' are metal - and act as the contact between the copper traces on the PCB.

PCB board - front. (excuse the poor focus)

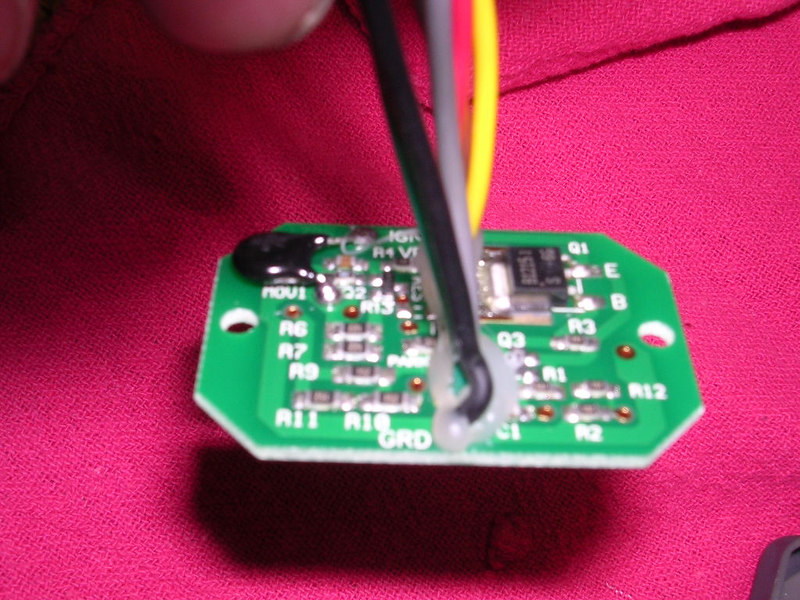

PCB board - back.

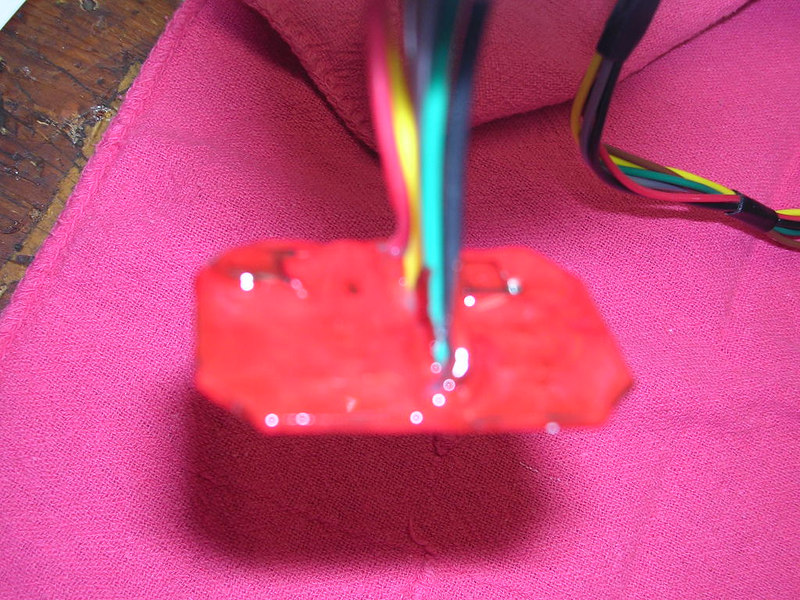

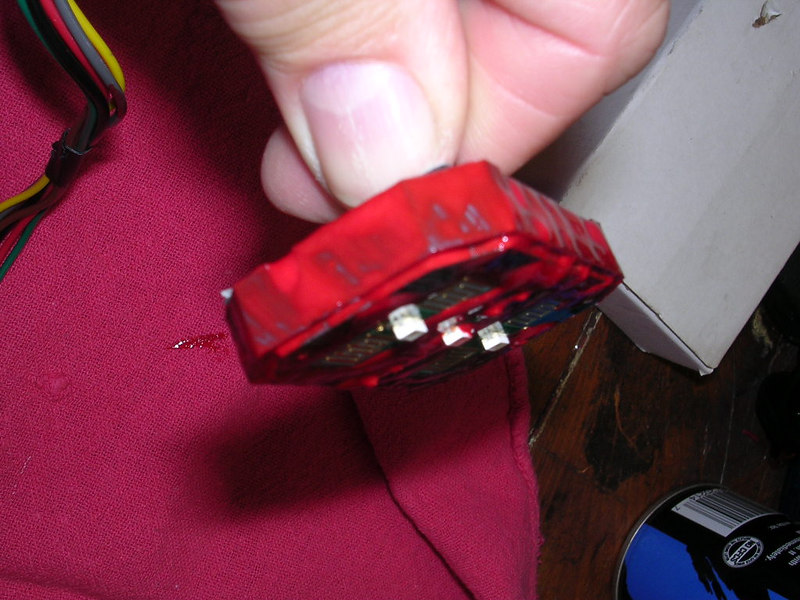

I use liquid tape to do this - it's available at just about any Home Depot in the electrical department - it's dielectric, waterproof, and NOT AGRESSIVE towards copper. I use the pretty red color - as it is easier to wipe off of some place it doesn't belong without leaving an extremely obvious smear, like the black stuff does. DAMHIK. :blink:

Others may prefer the manly black, however I believe it's available in the color of your choice which enables you to eliminate the chance of that unsightly smear clashing with your other farkles.

The proper treatment (IMHO, and experience) for the switch pad is to remove the PCB from the gray plastic case, so all you have is the board with the wires hanging out the back.

Then - you seal the board - edges and everything - with the exception of the copper traces directly underneath the little metal 'contact' pads that are part of the rubber cover - and of course, the light emitting diodes. Unless you don't like to see the pretty green pad at night.

Back - note the thick layer of liquid tape.

Then - once the back and edges of the board sealed, install it back in the housing.

Note how I left the word 'OFF' visible - so that I can ensure that I don't install the PCB back into the pad upside down.

And again, DAMHIK.

and then paint the outside edges of the inside switch housing - then seat them together.

This process seals the inside of the rubber switch cover onto the PCB, giving you a water tight membrane with the PCB inside.

Let it sit overnight or so - the liquid tape sets up very quickly - and you'll have a very waterproof switch housing. Install as usual in your control pad mount of choice.