There are at least several motors out there well in excess of 150k that are, IIRC, still running original chains and guides, but not necessarily original tensioners.

I am aware of none. There were only two 150k+ bikes out there (that I am personally aware of) before 03silverbullet' crash. Now there is just one - mine. 03silverbullet had a new (used) engine installed shortly after 100k after his original grenaded due to a lean condition by a improperly adjusted PCIII. My cam chain, tensioner, and guides were replaced at 110k. Not only are there no other 150k+ bikes out there that I am aware, but of the only three FJRs I know of that are between 100-150k, one has had the cam chain and tensioner replaced, and one just the tensioner. The third, I think had the tensioner replaced at 7X,XXX when it was having 'the tick' repaired. You'll have to ask big chief stinky pats (Or Mr. Lisa Stevens) about that. I am sure there are a few more 100k+ FJRs out there, but none that I am personally aware of.

As to the original post, I don't think what you are hearing is all that out of line. It's just the wording. No, you don't have to split the case to replace the 'guides'. HOWEVER, I believe the job to replace the cam chain, tensioner, and guides is pretty close to $1000 to complete when adding up parts and labor.

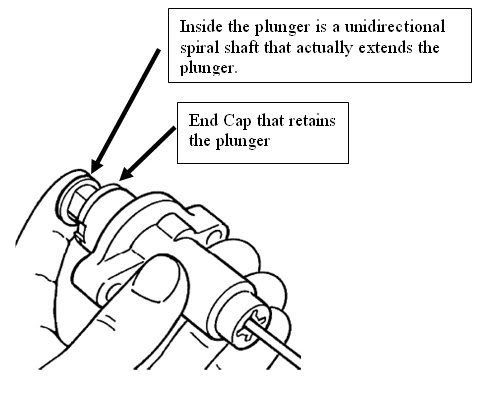

In my case the Y.E.S. payed for everything, but I think it would have cost around $1000. I had the noise, and by manually manipulating the CCT (Cam Chain Tensioner) it would go away. So, you would think that I either had a bad CCT or a stretched chain.

Well, CCTs are relatively, a known weak point on the FJR. They have been replaced on many an FJR that I am personally aware of. Some as early as 30,XXX miles, some as late as 110,xxx miles. The part is about $80 from a *discount* vendor, and is relatively a pain in the *** to change out due to the difficulty getting to a mounting bolt that is right next to the frame. (The way I understand it) It's about 3 hours of labor just to have a shop do the CCT IIRC. So if they are charging the $100/hr as most shops do around here, that's a $400+ job just for the CCT. This is just based on assumptions by me, so if somebody else knows different please speak up.

In my case, the shop just ASSUMED that due to the high miles (110k), that my noise was from a stretched cam chain. Based on their assumptions, they were going to replace the cam chain and guides. Why the guides, I have no idea as they didn't actually look at the old ones or anything. After talking with the tech one day and realizing he wasn't going to replace the CCT, I did my best to urge him to also replace that part telling him about all the FJRs out there that had already had them replaced. Fortunately, he listened to my advice and also ordered the CCT. (Imagine that!)

So all 3 items were replaced and my FJR was good again. They never did 'measure' the old chain to see if it was stretched. I saw the old guides and they 'looked' fine to my untrained eyes. The tech said the new ones were perhaps a bit softer that my old ones. They are a hard plastic, but I think (and he did too) that the old one's were fine.

Now, since all that was paid for by Y.E.S. I didn't care what they did as long as it was fixed. But I REALLY would have like to know if it was just a CCT problem (which is my suspicion), or if the cam chain was stretched also.

If I had been paying for it, and what I would do if I were you, is just have the CCT replaced and see if that solves your problem. I bet it will.

However, the one caveat is if the 'additional' cost to replace the chain is only a bit more because everything is opened up. The cam chain is a CHEAP part. Only like $19 - can you believe that? IIRC, each of the plastic guides was about $50, and of course the CCT around $100. You should be able to get current prices on those pieces online. Be aware, the cam chain was on back order when I did mine and I had to wait 3 weeks to get one from Japan.

You also have to ask yourself is it worth the risk, and the cost, to open the FJR up a second time if replacing the CCT doesn't fix it?

So how much extra labor is involved to remove the chain and either measure it, or replace it?

Like I said, $900 to replace all three sounds reasonable to me, and that will most definitely fix your problem, however if it was my $$$ I would just do the CCT first and see how it works.

Lots of examples of worn out CCTs being replaced out there, but I have not heard of one *known* streteched chain. (That was actually measured.)

Good luck and keep us informed. BTW, which dealer is it?