I finally got around to disassembling my gas cap and figuring out what is going on in there. It is NOT what has been previously assumed and discussed. I'm appending this onto the end of this previously existing thread, rather than creating a new one, as it makes sense to keep all the information on this fix together in one place. I was pointed to this thread for some tips on the dis-assembly. For that it was of great benefit.

Disassembling the cap and applying this "fix" is relatively minor surgery. You just need to have a clean workplace and be a bit careful about some of the small parts. Anyone that has ever done any carburetor work should not be intimidated in the least. Before beginning removal, you should flip open your fuel cap and stuff a small rag or paper towel into the filler neck before removing the cap assembly to keep small parts and dirt out of the tank.

When you remove the screws and pull off fuel tank cap assembly from the tank, you will most likely find a cruddy mess lies underneath, in what we will call the "well area" of the tank. Here's my 33k miles of spooge:

So, your first job is to carefully clean the entire well area. Clean the well well.

Here's a post clean-up picture identifying each of the various orifices and holes (front of bike is up)

S = Screw holes

D = Drain

V = Vent

And here is the corresponding under side of the cap assembly.

Note that only 3 of the 5 screws from the top ring of the cap hold the assembly onto the tank, plus one short screw from underneath the cap. The other two screws are "fakes" that just thread into the ring.

S = Screw holes

F = Fake screw holes

D = Drain

V1 = to Vent line

V2 = Tank vent

Here we can see the pathway for the tank venting. Pressure from within the tank would enter the cap at V2, pass through the cap assembly and exit the cap via the famous orange grommet at V1, and be passed out through the vent tube.

Fuel filling overflow is drained down into the well area via the two rectangular slots in either side of the cap assembly's rubber seal (marked D) and then drains off from the slightly depressed area in the well. That drain line is completely sealed from the tank when the lid is closed so it does not come into play for venting. Note that this drain hole depression is directly beneath one of the "fake" screws. You'll want to ensure that you always use one of the shorter screws in those fake screw locations so you do not inadvertently block off this drain hole.

First you'll want to remove the key from the cap. To do that you need to press down the rubber tank sealing ring on the cap. There is an interlock (shown later) that prevents the latch from being locked and the key removed unless the cap is fully seated. By depressing the ring you'll be simulating that.

Now it's time to disassemble the cap assembly. You'll want to do this on a clean workbench. Definitely not on top of the bike.

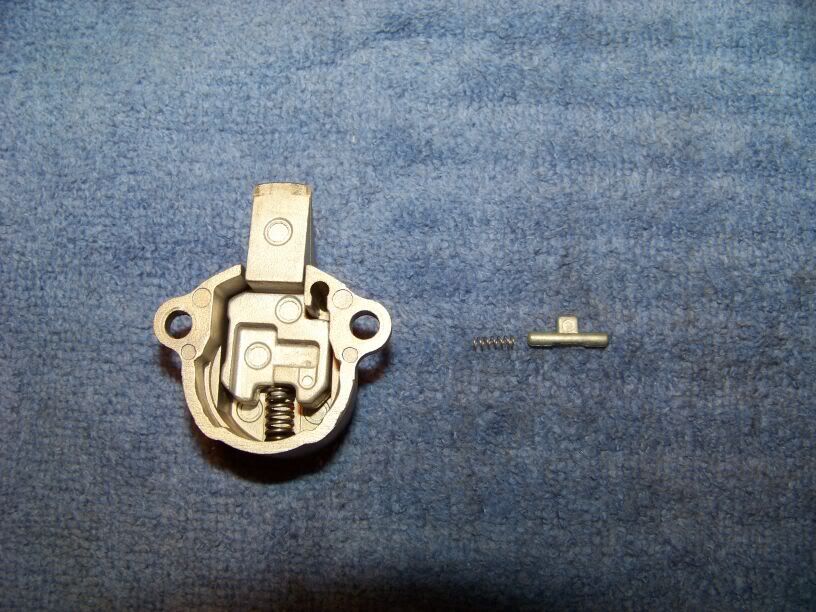

Flip open the cap lid and remove the two small screws that fasten the latch body to the cap. You'll feel some spring tension as you release these screws. More likely than not, when you go to lift off the latch, a small tee shaped widget and spring will probably fall out.

The widget is the key interlock we were talking about before. You can replace the spring into the appropriate hole and then slide the widget back into place as below. Or not. If you'd like the ability to remove your key from the gas cap with the cap open, you can eliminate the key interlock feature altogether by simply leaving the small spring a tee shaped widget out of the cap.

Set the lock subassembly aside and let's get back to the cap and integral vent. Here's what's left of the cap after latch is removed.

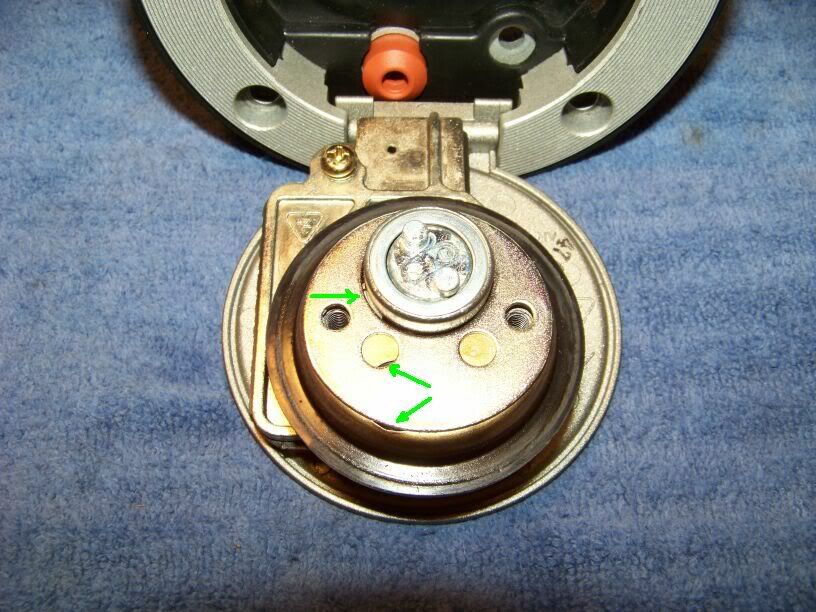

Some of the prior assumptions were that the plate that you now see on top must somehow move to allow venting. That is not true. There are lots of small gaps and cracks (arrows) that will allow plenty of air flow. There is no need to drill any additional holes in that plate to improve the venting.

Next remove that top plate and you will see the important parts of the tank ventilation. There are two vent paths:

Path C has a steel bearing fit snugly into a bore, that is used as a check valve.

Path F has some sort of a filter-looking restrictive thing jammed into it.

If the tank is under vacuum the ball bearing will be drawn away from the seat in the bottom of its bore and will allow air to pass freely into the tank. When the tank is under positive pressure, the escaping air will push the ball bearing up in its bore until it seats. Then the only path for exhaust ventilation will be through the more restrictive path.

The restrictive thingee is apparently there just to make it harder for the tank to vent, thereby building up positive pressure in the tank. It doesn't actually filter the incoming air as that is supposed to circumvent it through the unfiltered check valve. If the filter becomes clogged or overly restrictive, when the ball bearing closes off the tank, the tank will over pressurize. If the ball gets jammed in a sealed position when the fuel in the tank cools this could easily result in an imploded tank.

My "fix" for tank over-pressurization and potential implosions is to just remove the ball bearing. That, along with ensuring the vent hoses are clean and clear is all that is needed. Remove the steel ball and set it aside. Then re-assemble the cap in the reverse order of dis-assembly.

If you decided earlier that you want to keep the key interlock feature, just tip the latch assembly sideways as you reposition it on the cap so the spring loaded widget doesn't fall out again, and then hold the latch body firmly to the cap (don't push on the latch itself) until the screws are installed.

After completing the mod, you can test the ease of venting by pressing the end of a piece of vinyl or rubber hose to the small vent hole in the hinge side of the cap and alternately blowing or sucking on it. You will find that you now have free flowing ventilation in both directions