My 2007 A began to exhibit symptoms of ignition switch failure at about 8000 miles and on a fine morning shortly thereafter, as I started off on my daily commute, it failed altogether. No juice.

So, in one more triumph of hope over experience, I had the bike towed to the dealer I bought it from. Surely, I thought, this is not quantum mechanics. It is a well-documented problem of which I alerted the service department in enormous detail. Piece of cake.

That was on a Thursday. Friday the next week the dealer gets the bike onto a lift and by the Friday after that—two weeks after having the bike towed to the dealership—the dealer has successfully (wait for it) replaced the ECM. Said they could not duplicate the ignition problem.

I rode the bike home. It is such a pleasure to ride. During the week the switch performed flawlessly, but it continued to exhibit the symptom of faulty soldered connections: I could cause it to fail by tugging on the wiring harness (a diagnostic technique that apparently eluded the dealership).

The next weekend, thinking a loose wire and ready to solder, I followed DailyCommuter’s justly celebrated template for tearing down the switch, inspected the soldering and discovered absolutely nothing wrong; soldering was rock-solid.

By the way, it was a landfill in there; tiny bulldozers pushing around tiny piles of ground up leaves and trash.

So, on the hope that the problem was the dirt and after thoroughly cleaning and reassembling the switch, I put it on the multimeter (see Barabus’s seminal work in this area), which revealed an open circuit, no juice. But if the problem isn’t the soldering or dirt, then what is it?

As it happens, on inspecting the switch innards after again disassembling it, I find I can add yet another problem to the well-documented issues of faulty soldering and plain old dirt.

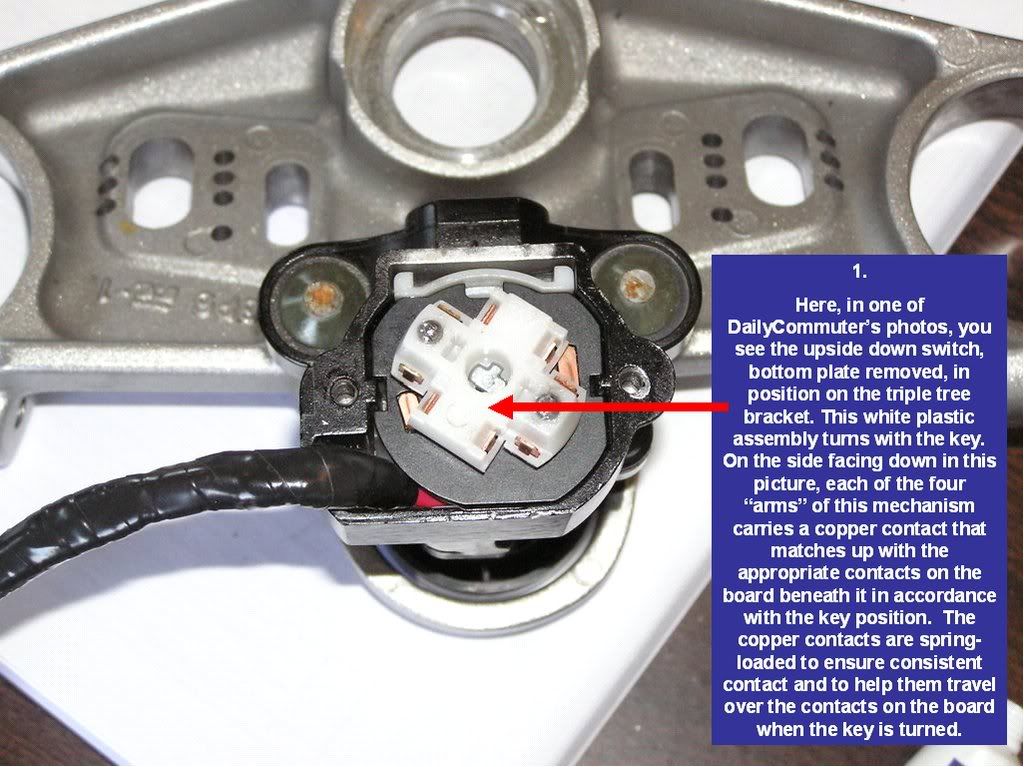

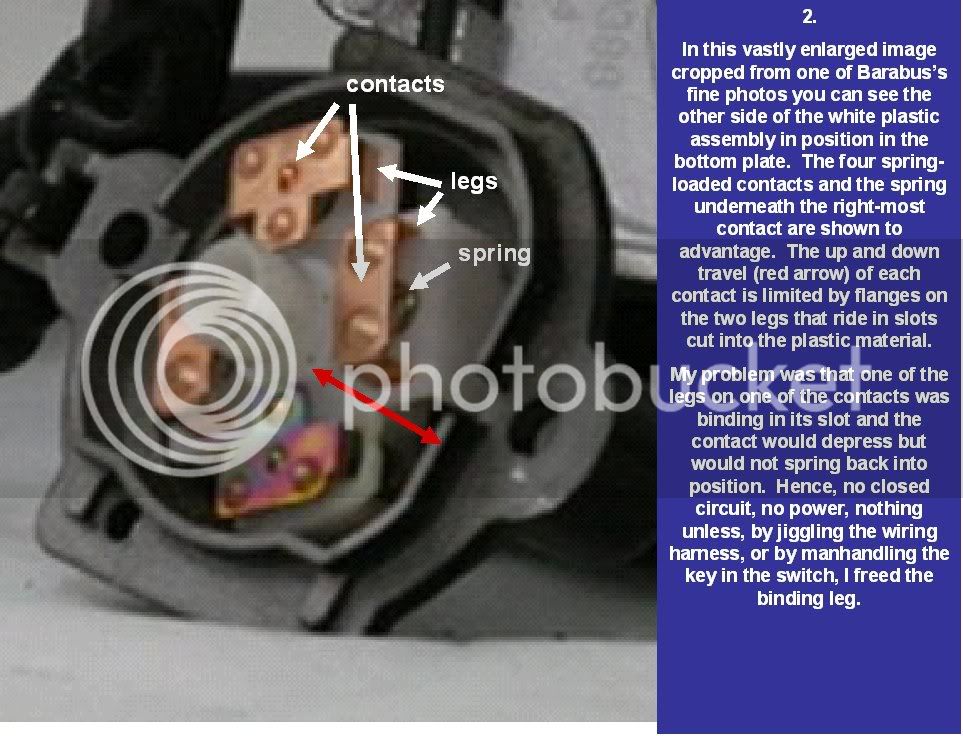

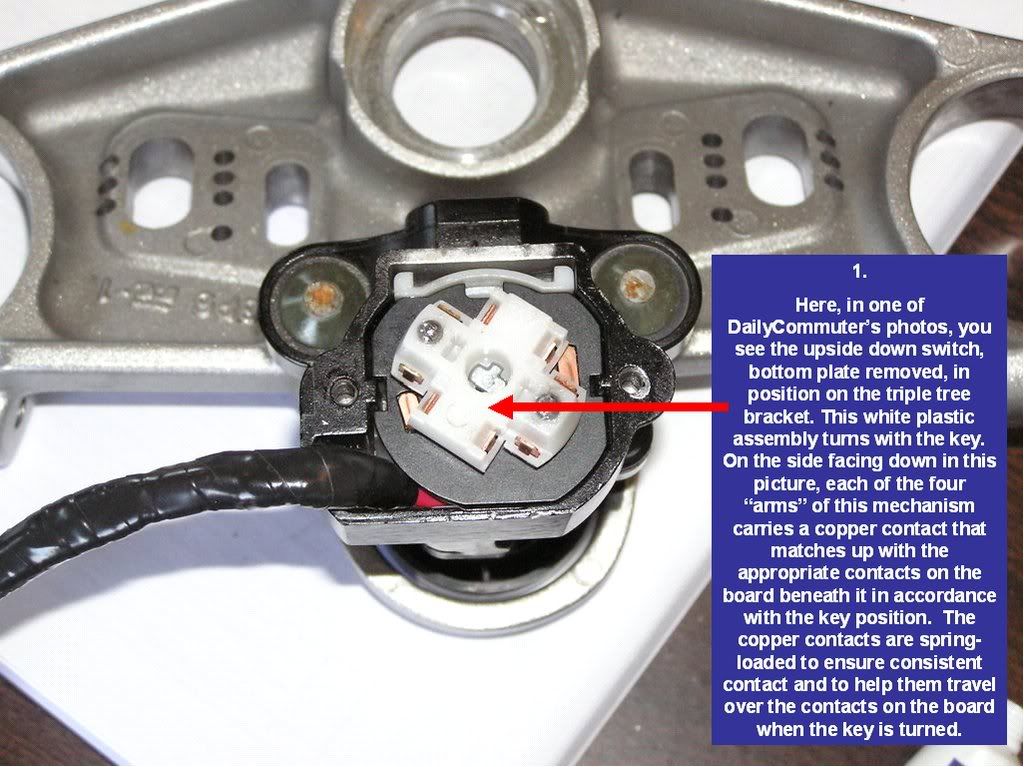

The point of failure in my case is the cross-shaped white plastic assembly in the bottom of the switch that turns with the key and that carries copper contacts that close (or not) the circuit when the key is in the proper position. This assembly is shown in the pictures below.

Of course, the question is: what happened to this assembly after eleven months of flawless performance that caused spring-loaded contact to bind? Does the switch heat up sufficiently to cause the plastic to deform and trap the leg of the contact?

My problem, before the switch failed altogether (and then recovered miraculously at the dealership) was that, intermittently, the switch would close only in some very delicate position between OFF and ON. Once the bike fired up, however, the circuit was very robust and I could turn the key all the way to its proper ON position with no consequences.

So, another mystery. Perhaps those of you who experience the betwixt-and-between key position syndrome, and who discover that it is NOT a loose wire and it is NOT dirt can take a lok at this assembly, which was the culprit in my case.

So, in one more triumph of hope over experience, I had the bike towed to the dealer I bought it from. Surely, I thought, this is not quantum mechanics. It is a well-documented problem of which I alerted the service department in enormous detail. Piece of cake.

That was on a Thursday. Friday the next week the dealer gets the bike onto a lift and by the Friday after that—two weeks after having the bike towed to the dealership—the dealer has successfully (wait for it) replaced the ECM. Said they could not duplicate the ignition problem.

I rode the bike home. It is such a pleasure to ride. During the week the switch performed flawlessly, but it continued to exhibit the symptom of faulty soldered connections: I could cause it to fail by tugging on the wiring harness (a diagnostic technique that apparently eluded the dealership).

The next weekend, thinking a loose wire and ready to solder, I followed DailyCommuter’s justly celebrated template for tearing down the switch, inspected the soldering and discovered absolutely nothing wrong; soldering was rock-solid.

By the way, it was a landfill in there; tiny bulldozers pushing around tiny piles of ground up leaves and trash.

So, on the hope that the problem was the dirt and after thoroughly cleaning and reassembling the switch, I put it on the multimeter (see Barabus’s seminal work in this area), which revealed an open circuit, no juice. But if the problem isn’t the soldering or dirt, then what is it?

As it happens, on inspecting the switch innards after again disassembling it, I find I can add yet another problem to the well-documented issues of faulty soldering and plain old dirt.

The point of failure in my case is the cross-shaped white plastic assembly in the bottom of the switch that turns with the key and that carries copper contacts that close (or not) the circuit when the key is in the proper position. This assembly is shown in the pictures below.

Of course, the question is: what happened to this assembly after eleven months of flawless performance that caused spring-loaded contact to bind? Does the switch heat up sufficiently to cause the plastic to deform and trap the leg of the contact?

My problem, before the switch failed altogether (and then recovered miraculously at the dealership) was that, intermittently, the switch would close only in some very delicate position between OFF and ON. Once the bike fired up, however, the circuit was very robust and I could turn the key all the way to its proper ON position with no consequences.

So, another mystery. Perhaps those of you who experience the betwixt-and-between key position syndrome, and who discover that it is NOT a loose wire and it is NOT dirt can take a lok at this assembly, which was the culprit in my case.

![fjackets Real Lambskin Leather Biker Jacket — Quilted Cafe Racer Zip Up Moto Leather Jackets For Men | [1100085] Johnson Brown, XL](https://m.media-amazon.com/images/I/41I7Pm1f+vL._SL500_.jpg)