wfooshee

O, Woe is me!!

RadioHowie's thread and Ionbeam's previous similar experience got me all paranoid, since I also have an '03 with some miles on it, about 59,000 at the moment. I figured I'd better look into it, but all the talk about how hard it is to get it outa there had me worried. In RadioHowie's thread Radman suggested just giving it a turn and see how it feels, so that's what I did. No need to pull the part for this easy check.

Easy job, I was 40 minutes from lifting the tank to closing the tool box.

Lift the tank, by now everybody knows you don't have to remove it, you can just prop it up. Of course, if you've got other work going on and have the tank off for something else, this can be part of that job without almost no additional effort.

If you don't know where the cam chain tensioner (hereinafter the CCT) is, have a look. Wires under it are probably not on your bike, they're from the battery to an underseat fuse box (click pics for larger version):

Highlighted here. light part is the CCT:

There's a 10mm bolt on the end that need to come off. You reach through the frame to get it. The hole through the frame has a rubbery cover on it. It helps tremendously to have a magnet stick to hold the socket inside the frame while you bring the extension in through the hole. My socket wouldn't go through the hole. Actual fingers have no place in here.

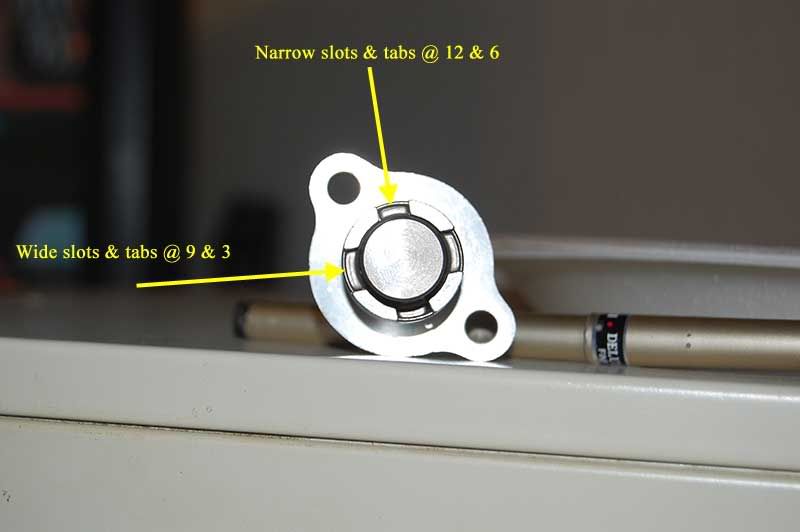

Once the bolt is out, you need a longish and VERY narrow straight-slot screwdriver. A 1/8" blade is too big. If you can turn the screw counterclockwise without resistance, then your CCT is shot. If you don't feel spring pressure when turning clockwise, like winding a clock, then your CCT is shot.

If, however, yours behaves as mine, no room to turn CCW, and turns freely CW against obvious spring pressure, returning by itself to the CCW direction, you can join me in having every confidence that your CCT is in good working order and is not at the limit of its travel.

You can bet that this is gonna be a regular check, though, like every oil change or thereabouts!

To get the bolt back in, I put a little RTV in the socket to act as a sticky hold. You do not want to be dropping stuff in there!

Easy job, I was 40 minutes from lifting the tank to closing the tool box.

Lift the tank, by now everybody knows you don't have to remove it, you can just prop it up. Of course, if you've got other work going on and have the tank off for something else, this can be part of that job without almost no additional effort.

If you don't know where the cam chain tensioner (hereinafter the CCT) is, have a look. Wires under it are probably not on your bike, they're from the battery to an underseat fuse box (click pics for larger version):

Highlighted here. light part is the CCT:

There's a 10mm bolt on the end that need to come off. You reach through the frame to get it. The hole through the frame has a rubbery cover on it. It helps tremendously to have a magnet stick to hold the socket inside the frame while you bring the extension in through the hole. My socket wouldn't go through the hole. Actual fingers have no place in here.

Once the bolt is out, you need a longish and VERY narrow straight-slot screwdriver. A 1/8" blade is too big. If you can turn the screw counterclockwise without resistance, then your CCT is shot. If you don't feel spring pressure when turning clockwise, like winding a clock, then your CCT is shot.

If, however, yours behaves as mine, no room to turn CCW, and turns freely CW against obvious spring pressure, returning by itself to the CCW direction, you can join me in having every confidence that your CCT is in good working order and is not at the limit of its travel.

You can bet that this is gonna be a regular check, though, like every oil change or thereabouts!

To get the bolt back in, I put a little RTV in the socket to act as a sticky hold. You do not want to be dropping stuff in there!

Last edited by a moderator: