Joe2Lmaker

Well-known member

Edit Oct 16, 2009: I started this thread back in 2007 as sort of a winter project. My idea was that I would share the entire process of design and fabrication. I thought it might be interesting for others to be part of the process beginning with defining the design parameters, and finishing with a working auxiliary tank. Just as I'm not a carpenter, but I still like watching Norm Abram and his New Yankee Workshop.

I didn't expect that the finished tank would only be the first. It wasn't until after I had my Tanji style tank finished and spent some time using it, that I changed my mind about my original design parameters. I've added this note for those who haven't been following this thread and are taking a look at it beginning with the first post. I hope you find some useful information here.

Dean Tanji designed an excellent a fuel cell. "FlatBed Fuel Cell" & Luggage Rack

These are no longer available. I've researched all kinds of solutions, but I really want a low profile with a flat top. I've decided to fabricate my own version.

I'm going to share my design ideas here. Hopefully this will be a project that some of you will find interesting.

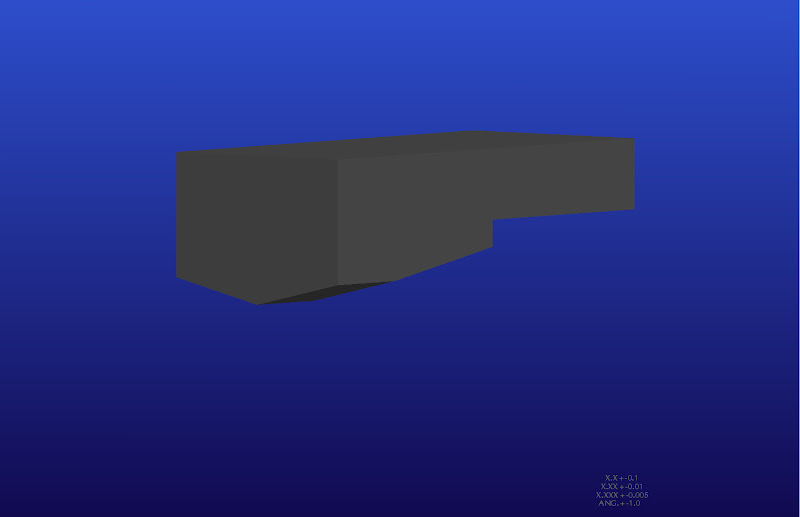

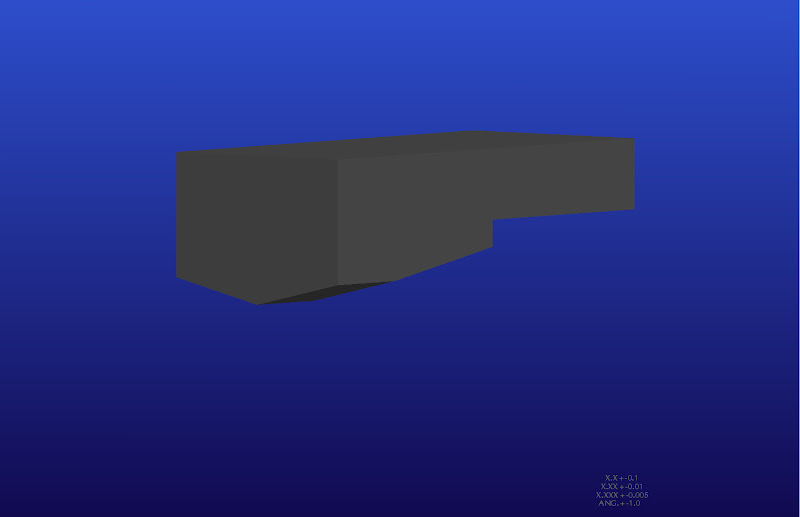

Here's the first CAD model:

(volume checks a little over the 4.8 gallon goal)

Here's the same view of the mock up:

More views of the scale model with the rear seat removed:

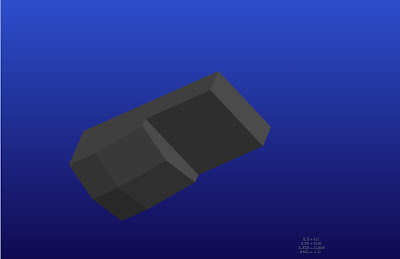

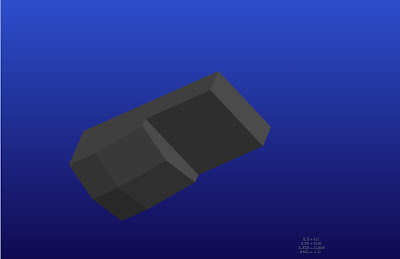

Here's sort of a bottom isometric view of the CAD model:

I wish I knew how to make a movie of the CAD model rotating. It would make it easier to visualize.

I already don't like how the flat top isn't level. I'll have to make some changes to correct that.

I'm open to suggestions. I'm trying to consider everything before I start cutting material.

I didn't expect that the finished tank would only be the first. It wasn't until after I had my Tanji style tank finished and spent some time using it, that I changed my mind about my original design parameters. I've added this note for those who haven't been following this thread and are taking a look at it beginning with the first post. I hope you find some useful information here.

Dean Tanji designed an excellent a fuel cell. "FlatBed Fuel Cell" & Luggage Rack

These are no longer available. I've researched all kinds of solutions, but I really want a low profile with a flat top. I've decided to fabricate my own version.

I'm going to share my design ideas here. Hopefully this will be a project that some of you will find interesting.

Here's the first CAD model:

(volume checks a little over the 4.8 gallon goal)

Here's the same view of the mock up:

More views of the scale model with the rear seat removed:

Here's sort of a bottom isometric view of the CAD model:

I wish I knew how to make a movie of the CAD model rotating. It would make it easier to visualize.

I already don't like how the flat top isn't level. I'll have to make some changes to correct that.

I'm open to suggestions. I'm trying to consider everything before I start cutting material.

Last edited by a moderator: