bob61

Active member

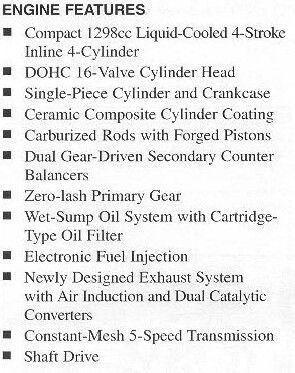

Should I feel like Yamaha went from a dress shirt to a cheap T shirt? What good is this sleeveless, or plated cylinder wall that's new for 2013? What was wrong with the old design? The engine was great, why did they have to change it? Anyone know if this new design will last the miles (and miles) the old engine was good for? Want a generation 3, but do I need to wait and see if this plated cylinder wall is as good as the original?