reaction57

Well-known member

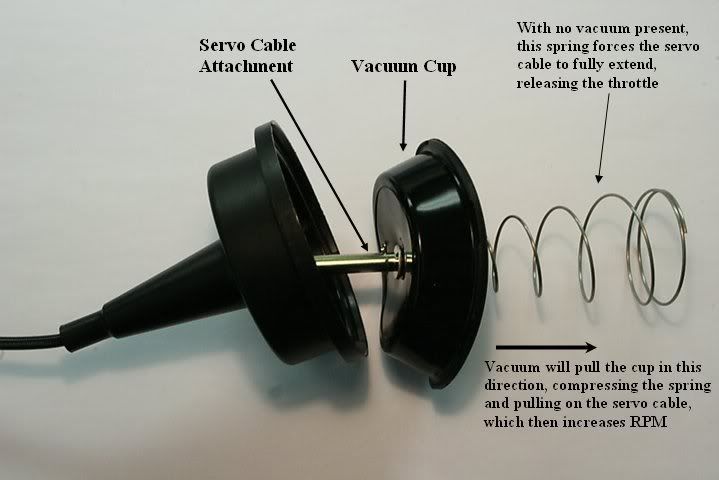

Well I am finally at the end of my audiovox cruise control install! It has been a major P.I.T.A for me! I have almost given up numerous times! My question is on how to set the ball and chain slack. There is not a lot of talk of how to do this part only if its not right it will cause problems! So is it no slack with trottle fully closed or open? I messed up on drilling the tang, being alittle off center to the top. I'm worried it might wear thru over time!

Completely unrelated. Has anyone ran the audiovox cruise with the Mccruise cable interface?

Thanks for any and all help. This forum rocks!

Completely unrelated. Has anyone ran the audiovox cruise with the Mccruise cable interface?

Thanks for any and all help. This forum rocks!

![fjackets Real Lambskin Leather Biker Jacket — Quilted Cafe Racer Zip Up Moto Leather Jackets For Men | [1100085] Johnson Brown, XL](https://m.media-amazon.com/images/I/41I7Pm1f+vL._SL500_.jpg)