OK, I think Gary will have a nice product for you all. After we tweaked the prototype, it fit nicely and allowed both the stock grab rail or his modified Givi rack to be used. You'll have to remove the cowling, at least one side, in order to install but that's pretty easy to do. Here are a couple pics to show you what it looks like.

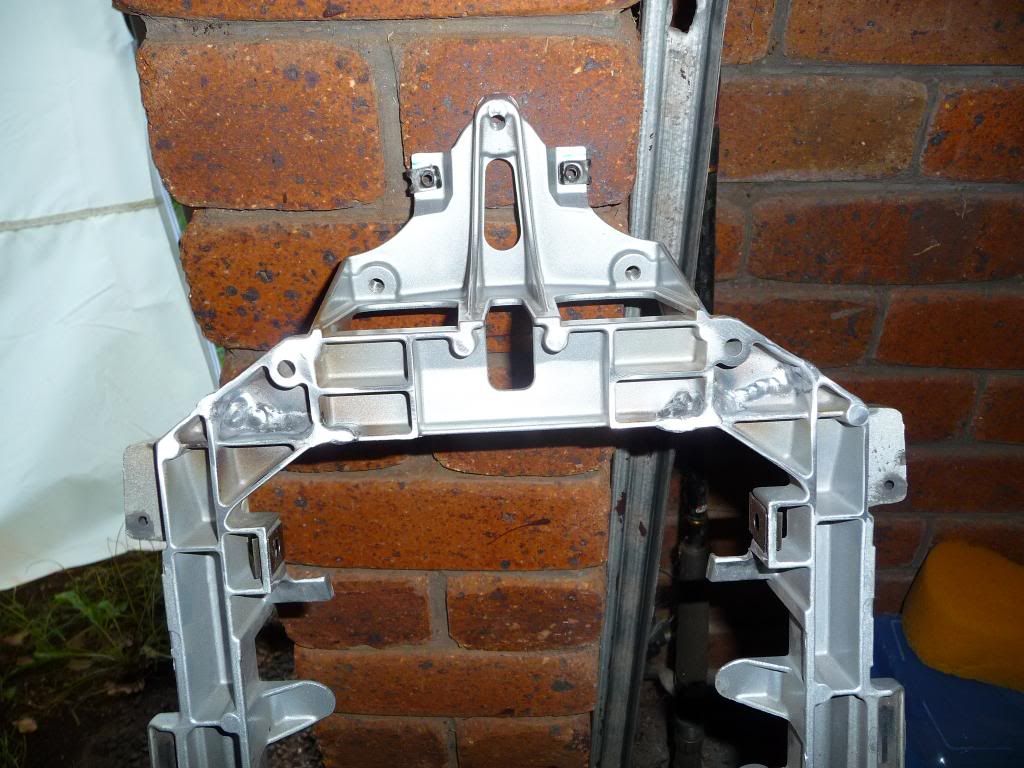

This is the stiffy after I had to cut and trim the sides in order to allow the left and right sides of the cowling to fit properly.

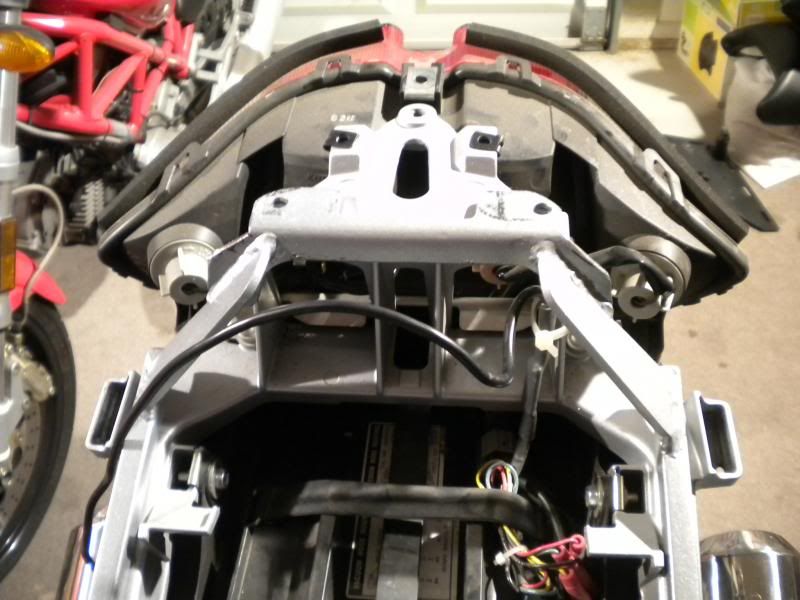

This pic shows the stiffy installed

I had to remove the foam pieces that cushion the cowling against the subframe and just placed a piece of fuzzy side velcro in its place to provide a little protection between the plastic of the cowling. Here is a pic of the piece of foam that is glued to the cowling. This acted as enough of a interference that when the added thickness of the stiffy, it wouldn't allow the cowling to sit properly. Once you remove it, the cowling would lay properly and allow you to attach the mounting bolts.

Once everything was installed, the stock grab rail installed perfectly using the stock bolts. and a spacer Gary provided for the most rearward attach bolt. This spacer accounts for the extra thickness of the stiffy that the front two mounting bolts are now seeing. I didn't take a picture with the stock grab rail but here is a pic with the Givi mount attached.

Here is a close up of the cutout that is necessary to allow the Givi rack to attach the modified mount.

And then here is a pic showing the mount with the backrest installed.

Another shot of the backrest

All in all, I feel good about the extra support the stiffy will provide, even with the Givi rack.......I mean, isn't overkill better?

For anyone using the stock grab rail, or the popular PCA rack, the stiffy will provide some much needed strength.

Thank you Gary!!!!!