GeorgiaRoller

Exit Stage Left

Last week in Virginia my glove box latch decided it had enough. I figured out that a small plastic peice had broken off from underneath the button and it would not engage and stay latched anymore. I also learned that you can't just purchase a new button from Yamaha & you have to replace the entire glove box "sub-assembly" for over $100.00. So I did a $7 fix that allows me to use my current glove box with the only caveat being that it's not "locked" when you turn off the bike. That being said I never kept anything valuable in there anyways and if I did I'd always put it in my jacket if I went into a restaurant or hotel for the night and I never left anything in the glove box overnight. On the plus side now I can open/close the glove at will and not have to make sure I have the bike in "neutral" as was the case before.

So here's what I did. Perhaps this will help someone else out with the same issue & it only cost about $7.00

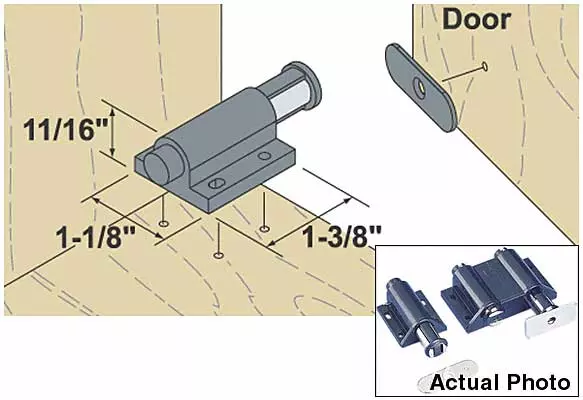

Went to Lowe's and bought a box of these 3/4" magnets for $2.98... which you'll only need to use one of them.

And I bought this Loctite Epoxy for $3.77. I found in my shop (2) of these metal latch strike plates as well that came off a cabinet latch assembly. (Free)

I attached the first metal strike plate here on the upper corner of the underside of the cover.

Then I attached the other strike plate here and let that setup. Once that was in place and the epoxy had dried, I found that this location at the top edge of the strike plate was the best place to put (1) of the 3/4" magnets. I tested the latch opening/closing several times to be sure this was the best location that provided the maximum amount of surface strike to the plate on the underside of the glove box door. Then I epoxy the magnent here.

Then I gentley used a flathead screwdriver and inserted it under the plastic push button and lifted it out as well as the rubber grommet underneath it to expose the latch mechanism. You'll want to pull out the plastic strike piece so that the door can freely swing down and not hit anything. Since the latch is broken there is no point in having any of the loose peices down here anymore & it will just get in the way with the door operating now.

This is what it should look like when your done. After you removed the strike piece reinstall the rubber grommet & plastic push button.

Here is how it looks when shut. Just like new. No one would ever know!

There is approx. a 1/4" gap between the underside of your glove box door and the contact area of the glove box assembly when the door is shut. This is because of the lip that protrudes down that recesses inside the box sub-assembly to make for a watertight seal. Sooooo it just so happens to be about perfect if you use (1) strike plate under the door & (1) strike plate on top of the box sub-assembly and then just (1) 3/4" magnent. This closes off that gap and the seal is just about the exact same as with the factory latch working. Plus this allows the door to "snap" shut. I like this much better than trying to mess with velcro which will eventually wear out over time and loose it's effectiveness.

So here's what I did. Perhaps this will help someone else out with the same issue & it only cost about $7.00

Went to Lowe's and bought a box of these 3/4" magnets for $2.98... which you'll only need to use one of them.

And I bought this Loctite Epoxy for $3.77. I found in my shop (2) of these metal latch strike plates as well that came off a cabinet latch assembly. (Free)

I attached the first metal strike plate here on the upper corner of the underside of the cover.

Then I attached the other strike plate here and let that setup. Once that was in place and the epoxy had dried, I found that this location at the top edge of the strike plate was the best place to put (1) of the 3/4" magnets. I tested the latch opening/closing several times to be sure this was the best location that provided the maximum amount of surface strike to the plate on the underside of the glove box door. Then I epoxy the magnent here.

Then I gentley used a flathead screwdriver and inserted it under the plastic push button and lifted it out as well as the rubber grommet underneath it to expose the latch mechanism. You'll want to pull out the plastic strike piece so that the door can freely swing down and not hit anything. Since the latch is broken there is no point in having any of the loose peices down here anymore & it will just get in the way with the door operating now.

This is what it should look like when your done. After you removed the strike piece reinstall the rubber grommet & plastic push button.

Here is how it looks when shut. Just like new. No one would ever know!

There is approx. a 1/4" gap between the underside of your glove box door and the contact area of the glove box assembly when the door is shut. This is because of the lip that protrudes down that recesses inside the box sub-assembly to make for a watertight seal. Sooooo it just so happens to be about perfect if you use (1) strike plate under the door & (1) strike plate on top of the box sub-assembly and then just (1) 3/4" magnent. This closes off that gap and the seal is just about the exact same as with the factory latch working. Plus this allows the door to "snap" shut. I like this much better than trying to mess with velcro which will eventually wear out over time and loose it's effectiveness.