The Other Brian

Well-known member

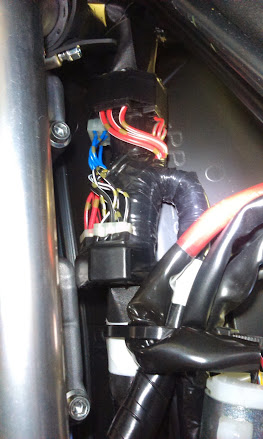

I acquired a new to me 2010 FJR with just over 11,000 miles on it this past August. The bike is parked and stripped of its

plastic to fix a rumble occurring when the wind shield retracts and to add a fuse block and a relay controlled circuit to power my heated gear.

I have read most of the threads regarding the Ground Spider issue and based on what I have read the jury is out weather it was resolved by 2010.

How can I tell if the spider is going to bite me or already has? I have not noticed any electrical issues in the few

thousand miles I have put it since its acquisition.

What can be done by me to prevent a spider bite?

plastic to fix a rumble occurring when the wind shield retracts and to add a fuse block and a relay controlled circuit to power my heated gear.

I have read most of the threads regarding the Ground Spider issue and based on what I have read the jury is out weather it was resolved by 2010.

How can I tell if the spider is going to bite me or already has? I have not noticed any electrical issues in the few

thousand miles I have put it since its acquisition.

What can be done by me to prevent a spider bite?

Last edited by a moderator: