Been researching alot about all the great ideas people are putting into auxiliary tanks and still have yet to see anything done in fiberglass. So heres my concept: something much like the Corbin smuggler, molded as low and foward as possible to centralize mass, enough flat top to attatch some sort of rack, but keeping foward of the original top trunk. Also along the same line, pushing the width to 16-17 inches to just clear the bag latches..... I realize that aluminum is more accepted, but f/g is my specialty (have made many gas/diesel tanks for boats), so the issues with fittings etc. are minimal. The idea of having a tank that 'fits' the bike rather than something that resembels a milk crate is very appealing. I realize that it would probably have to be a 'pump tank'.....thoughts? suggestions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

not another aux tank thread!

- Thread starter hyndsight

- Start date

Help Support Yamaha FJR Motorcycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

5 gallons or more of extra gas in a fiberglass shell cracking open like a pinata? No thanks. There's a reason fuel cells are made from materials like aluminum and not from fiberglass.Been researching alot about all the great ideas people are putting into auxiliary tanks and still have yet to see anything done in fiberglass. ....thoughts? suggestions?

If you're still wanting to do one for yourself....don't expect it will pass tech inspection at any rally.

madmike2

Shtirrenuppenmeister

/\ /\ /\ /\ /\ /\ /\

Whut hee sayed!

En cased ther wuz ever a thyme win thet murdersickle wuz tuh fine itseff fallin' en floppin' er tumblin', I'm a thinkin' et a metal extry tank kud git sum dents en not be openin' upta be spillin' thems dinosaurius juices onta hot engine er exhaustive parts.

Boom! Poof! Prolly knot thuh sounds yew wanna be hearin' iffen yer layin' onta thems grounds.

Whut hee sayed!

En cased ther wuz ever a thyme win thet murdersickle wuz tuh fine itseff fallin' en floppin' er tumblin', I'm a thinkin' et a metal extry tank kud git sum dents en not be openin' upta be spillin' thems dinosaurius juices onta hot engine er exhaustive parts.

Boom! Poof! Prolly knot thuh sounds yew wanna be hearin' iffen yer layin' onta thems grounds.

SkooterG

Purveyor of Crooked Facts

I am not a materials engineer, however, I would have serious doubts that fiberglass would be 'SkooterG Proof'.

FJRay

Well-known member

I agree with the OP. It sems that Triumph used fiber glass tanks in the 60s and the biggest problem was using white pump chevron gas cause it would eat the tank. We don't have real gas anymore so thats out. I have also built tanks that were coast guard approved and have seen DOT approved glass tanks. With the right materials it can be plenty strong. Getting it past tech might take some education and knowledge of other materials. Would like to see one built.

$44.99

Real Time Industries Reflective Decals for Yamaha FJR1300 Gen 2 Fairing (Black - Silver Print)

Real Time Industries

Joe2Lmaker

Well-known member

It could be done, with the right tools and expertise.

The 2007 Iron Butt Rally Day -2

"The custom Kevlar and carbon fiber tank that Bob and Silvie Torter had built to increase the fuel capacity of their K1200GT to 10.5 gallons looks like it came right out of the BMW factory." - https://www.ironbuttrally.com/IBR/2007.cfm?DocID=30

Plus, Fuel Safe builds composite tanks. https://www.fuelsafe.com/index.htm

Start a thread. Document the whole project. I'd read it.

The 2007 Iron Butt Rally Day -2

"The custom Kevlar and carbon fiber tank that Bob and Silvie Torter had built to increase the fuel capacity of their K1200GT to 10.5 gallons looks like it came right out of the BMW factory." - https://www.ironbuttrally.com/IBR/2007.cfm?DocID=30

Plus, Fuel Safe builds composite tanks. https://www.fuelsafe.com/index.htm

Start a thread. Document the whole project. I'd read it.

BwanaDik

Well-known member

I'm actually currently working on something very similar to what hyndsight is describing. It's based on a standard pillion seat (just got it last week from another forum member) base with thru bolts to bolt it to the bike frame (per the regs). There are seat "landing areas" on the sub frame that look like they can be drilled and tapped for the hold down bolts. The bolts would go all the way thru the tank from the top with some sort of indention to make them flush with the top. Mock up in foam (in progress but no pics) very similar in shape to a Smuggler stuck on top of the seat base for shaping and mounting. I just haven't decided whether to use FG or AL. I can do 'glass pretty well but haven't tried my hand at Aluminum from scratch yet. Maybe even light gauge steel as I've done some car body work in the past and have a MIG welder.

I've never liked the "milk crate" look either. Plus, none of the aux tank designs I've seen protect the area underneath them. They all seem to allow the elements to go right underneath (rain, snow, dust, etc.). I've got the bike ECU, the AE ECU, PCIII and a Fuzeblock with relays under there, plus tools, rags, owners manuals, other stuff. Seems like that should have a minimum of weather protection.

Using the seat base as a guide, I'm figuring I can dulicate the same shape that the seat bottom has to semi-seal the underseat area, possibly with a rubber seal like under the hood of a car, then model the actual tank after the Smuggler on top of it with some sort of flat spot and tie-downs to hook stuff to. Weld it all up with an electric transfer pump and pipe it into the GenII fuel system as described elsewhere.

I'm also trying to get my New-to-you '72 BMW 3.0 CSi on the road reliably so I've got a lot of irons in the fire right now. Plus that four letter word......WORK *@#(*^(@( keeps getting in the way. But it's getting to that time of year here in Houston when it's 80 degrees at 6 AM so I may have a lot of non-riding time to work on it.

Stay tuned......

I've never liked the "milk crate" look either. Plus, none of the aux tank designs I've seen protect the area underneath them. They all seem to allow the elements to go right underneath (rain, snow, dust, etc.). I've got the bike ECU, the AE ECU, PCIII and a Fuzeblock with relays under there, plus tools, rags, owners manuals, other stuff. Seems like that should have a minimum of weather protection.

Using the seat base as a guide, I'm figuring I can dulicate the same shape that the seat bottom has to semi-seal the underseat area, possibly with a rubber seal like under the hood of a car, then model the actual tank after the Smuggler on top of it with some sort of flat spot and tie-downs to hook stuff to. Weld it all up with an electric transfer pump and pipe it into the GenII fuel system as described elsewhere.

I'm also trying to get my New-to-you '72 BMW 3.0 CSi on the road reliably so I've got a lot of irons in the fire right now. Plus that four letter word......WORK *@#(*^(@( keeps getting in the way. But it's getting to that time of year here in Houston when it's 80 degrees at 6 AM so I may have a lot of non-riding time to work on it.

Stay tuned......

chivvalry

Well-known member

I like the idea... and I'm not convinced that a FG tank would be much less safe than an aluminum tank. Welds can pop and fittings get ripped off of anything in an accident. Hate the milk crate look.

Have to get skooterg to test it out after you get it built...

Edit: From the same article linked above... "A decent auxiliary fuel system can be assembled for a few hundred dollars if you start with an off-the-shelf high-density polyethylene tank and mount it to the sub-frame under the pillion seat"

Have to get skooterg to test it out after you get it built...

Edit: From the same article linked above... "A decent auxiliary fuel system can be assembled for a few hundred dollars if you start with an off-the-shelf high-density polyethylene tank and mount it to the sub-frame under the pillion seat"

Last edited by a moderator:

Joe2Lmaker

Well-known member

"milk crate"?

Whatchu talk'n 'bout Willis?

Whatchu talk'n 'bout Willis?

BwanaDik

Well-known member

Sorry, no offence intended. You really do nice work."milk crate"?

Whatchu talk'n 'bout Willis?

Joe2Lmaker

Well-known member

Not offended.Sorry, no offence intended. You really do nice work."milk crate"?

Whatchu talk'n 'bout Willis?

Just kidding around

:crazy: (note:change topic to "extry tank thread") :crazy:En cased ther wuz ever a thyme win thet murdersickle wuz tuh fine itseff fallin' en floppin' er tumblin', I'm a thinkin' et a metal extry tank kud git sum dents en not be openin' upta be spillin' thems dinosaurius juices onta hot engine er exhaustive parts.

Boom! Poof! Prolly knot thuh sounds yew wanna be hearin' iffen yer layin' onta thems grounds.

Joe2lmaker: Was'nt pickin on yer wurk (now I'm doing it!), 'milk crate' was refering to the plastic tanks that (as you know) are functional, ecomomical, fugly, and........ tempting.....btw, thanks for sharing your tank story, lots of valuable info in there.

So now I'm on the fence.....

I'm pretty confident I could fab a 'SkooterG proof' tank, but there are some manufacturing 'issues' to I would have to work through to get the 'look' I want.

Looking at more pre-fab options and Tourtank makes an 10"x14" 4 gal cylinder that for $200 looks pretty appealing...

Another tangent I was thinking about today was molding a f/g shell with the right look, and then mounting a pre-fab inside it for the 'function' part......obvious drawback is that use of space is compromised......hmmm

Joe2Lmaker

Well-known member

You don't like the milk jug look, but you do like the beer keg look?Looking at more pre-fab options and Tourtank makes an 10"x14" 4 gal cylinder that for $200 looks pretty appealing...

How would you feel about making a fiberglass skirt to go under an aluminum tank? I know a guy who has a design for an aluminum GenI tank.Another tangent I was thinking about today was molding a f/g shell with the right look, and then mounting a pre-fab inside it for the 'function' part......obvious drawback is that use of space is compromised......hmmm

BwanaDik, If you're still following this... interested in something similar for the GenII?

The tanks are the same, but the GenI and GenII mounting systems will be different. If I have two tanks of this design made (one for hyndsight and one for BwanaDik), I can make my two tank minimum order at the fab shop that builds these for me. There is a lot less welding in this design and no counterbore bungs through the tank. The cost should be relatively low, even cheap.

JamesK

Got to ride

I'm still actively following this discussion. I too would like the cheap/cheaper solution in a more form-fitting look.

BwanaDik

Well-known member

Still here!

JL2M So what you're proposing is some how making a form fitting base with your AL tank mounted on top? Hmmm.....Might work.

One thing I didn't mention above was that my design was not intended to meet the IBA max fuel capacity. I'm just going for extra fuel with a stylish look. I'll figure out the dimensions of an IBA tank this weekend to see if it will look like I've got a dead whale on the back.

JL2M So what you're proposing is some how making a form fitting base with your AL tank mounted on top? Hmmm.....Might work.

One thing I didn't mention above was that my design was not intended to meet the IBA max fuel capacity. I'm just going for extra fuel with a stylish look. I'll figure out the dimensions of an IBA tank this weekend to see if it will look like I've got a dead whale on the back.

I brew my own, what can I say? :drinks:You don't like the milk jug look, but you do like the beer keg look?

So you are saying a 'shelf' that would fill the voids on either side and create a platform that your tank would be bolted to, or through?really cool, form fitting, fiberglass storage area with rigid attachment points to the bike's rear subframe, the tank could mount above that.

Joe2Lmaker

Well-known member

A few years back, I toyed with the idea of a rack that replaced the rear seat and mounting my tank to that rack.So you are saying a 'shelf' that would fill the voids on either side and create a platform that your tank would be bolted to, or through?

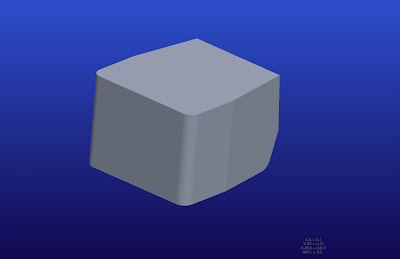

This is what the first revision of that idea looked like:

I then opted to mount the tank directly to the bike. My reasoning was that the tank might be less expensive to build if it mounted to a rack, but the cost of the rack would just erase any savings and add an extra piece to deal with. The Tag-Along Tank seemed easier to use. The downside was that it doesn't work for GenI owners and then we found out that it doesn't work well if the GenII rider's seat is in the low position.

So, I'm back to considering an aluminum frame/bracket that attaches to the rear subframe and attaching the tank to that.

If you look at the photos above, you can see there is a lot of open area around the frame. The frame could be redesigned to accommodate storage under the tank, but that won't close up all the open spaces. My solution was a plastic enclosure (toolmaker thinking). I thought maybe I could make a drape forming mold or a vacuum mold and drape form sheets of plastic that would follow the various contours of the bike. I'm not going to have any time to play with that idea until next winter, but if you build your own out of fiberglass...

You could mount one of these to it:

This would hold the IBR max volume for the FJR and could be made out of three sheets, formed and welded together. There are fewer bends, fewer pieces, and less welding. The cost would be about as low as you're going to get. If you don't like the shape, or think it's milk juggish, sorry. I really like the way it looks. Especially with the flush mount JAZ cap!

I would still like to see a thread about a custom composite tank project for the FJR. I'm not attempting a thread hijack, just trying to help.

Gramps

Well-known member

What about (and I want to say up front, I have no mech. design knowledge at all & tend to say things I can't prove :umnik: ), making a fiberglass shell & using a fuel grade rubber bladder.

First of all, on a forum like this I believe there is no such thing as thread 'hijacking', we are here to throw ideas around and try to learn from others experiences, so the more ideas the better  Joe, you have invested so much into this topic so I value your ideas highly. Oh, and btw, as 'square' as the Tag Along is, It's still a beautifull thing B)

Joe, you have invested so much into this topic so I value your ideas highly. Oh, and btw, as 'square' as the Tag Along is, It's still a beautifull thing B)

So what are your thoughts on attatchment if I did come up with a composite piece? Seems like it would be hard to compete with the simplicity/strength of your TA tank mount.

Gramps: That is something I had thought of in the shell/integral tank concept, but it seems like the bladder manufacturers are all building bigger stuff. I'de have to price custom and also wonder about certification issues. Definately worth a look though.

So what are your thoughts on attatchment if I did come up with a composite piece? Seems like it would be hard to compete with the simplicity/strength of your TA tank mount.

Gramps: That is something I had thought of in the shell/integral tank concept, but it seems like the bladder manufacturers are all building bigger stuff. I'de have to price custom and also wonder about certification issues. Definately worth a look though.

Similar threads

- Replies

- 58

- Views

- 5K

- Replies

- 12

- Views

- 773

- Replies

- 73

- Views

- 5K