RadioHowie

I Miss Beemerdons!

Trying to get some work done...deep cleaning...battery maintenance...farkle installs...and need to get the tupperware off.

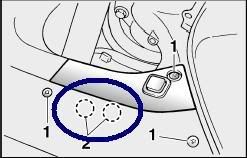

Jeezus, what a nightmare I'm having! From Image #1 above, how the hell do you get the two plastic panel screws out? I know they're basically pop-in screws that spread the insides of the grommets to hold two panels together, but the grommets themselves just turn and turn. Can't get both my big, fat hands in there to grab the back of the grommet (on the inside of the panel holding the glovebox) and can't get a grip on the outside of the grommets to keep 'em from spinning so the screw comes out. Any suggestions short of oxyacetylene?

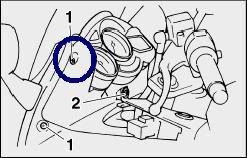

For image #2, I'm missing the screw, and I'm guessing, the spring nut behind the panel.

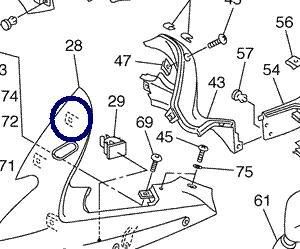

I guess I can get both from the dealer, but looking at image #3, where the hell does the spring nut, #47 on the diagram, attach to? The tab I circled on the headlight surround?

I wouldn't have to ask if I could get the panels off.