Always too busy to do my own maintenance (Least that was my excuse) Drop the bike off and pay the serious cash for anything besides fluid changes and simple farkling procedures...

Until recently that is. My frustration has been building with relying on others (Especially the local Yamaha Dealership) to do anything I felt would be too tech or too time consuming for me

to do. I had a flat tire on a return trip from Iowa, which I plugged and returned back to Florida with. The rear tire had only 15k on it and was good for another 3k (At least)

I made a ride to Daytona and on the return ride home to WPB the tire went flat again. I noticed a "Mushy" feeling and pulled into a rest stop that was only 1.5 miles further down the road.

When I checked the tire it was 8 lbs PSI and soft/hot. The tire had spit its sticky string.(A first for me) I stuck another string in and rode the remain 160 miles home. The bike began to develope

a wobble on the way home. I parked the bike and started riding my Dakar. (I have only bikes now) The '05 FJR sat until curiosity won the day and I decided to try swapping an used tire I

had sitting around. I had never even removed a rear tire from the bike. After purchasing the needed tools, I consulted FJRTECH and performed the swap.

Here are some pics:

The original hole (Plugged)

The damaged Plys inside that caused the wobble (No noticeable damage on outside of tire)

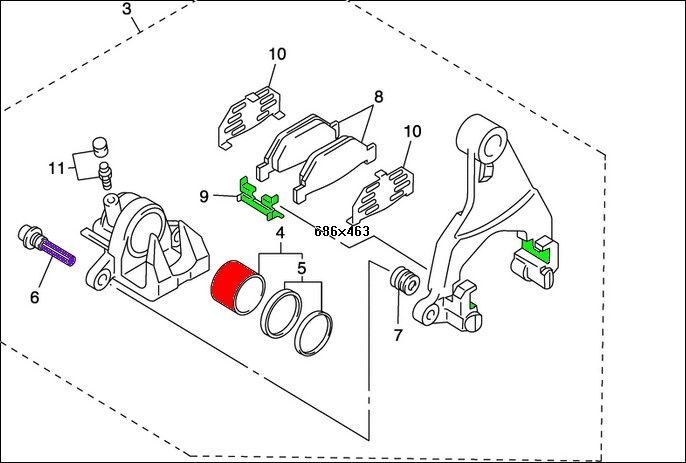

Now when I went to reassemble the tire on the bike, I reversed the procedure. When I got the spacer/washer installed AS I DISASSEMBLED IT, the washer seemed "Misplaced". I consulted

the instructions... I found the washer WAS misplaced. It had been placed between the spacer and the caliper! I pulled the axel and put it where it belonged. Now I am wondering just how long

it had been reversed? I have gone through 2 sets of brakes in the last year, which I thought was due to the IBR and the Haul Rd. Now I am wondering if the washer was misplaced and then

reinstalled incorrectly each time after? I guess I will be taking the time to do the work myself from here on out. The procedure was embarrassingly easy.

Now I have learned some things:

Spooning isn't always fun

Never ride on a flat (Even 2 miles)

Doing your own maintenance is cool (If you have the time)

5 gallon buckets don't make the best tire work stands

Tools, tools, and more tools are needed

Oh, most importantly... a big thanks to the guys that have done the work on the "How to(s)"

Until recently that is. My frustration has been building with relying on others (Especially the local Yamaha Dealership) to do anything I felt would be too tech or too time consuming for me

to do. I had a flat tire on a return trip from Iowa, which I plugged and returned back to Florida with. The rear tire had only 15k on it and was good for another 3k (At least)

I made a ride to Daytona and on the return ride home to WPB the tire went flat again. I noticed a "Mushy" feeling and pulled into a rest stop that was only 1.5 miles further down the road.

When I checked the tire it was 8 lbs PSI and soft/hot. The tire had spit its sticky string.(A first for me) I stuck another string in and rode the remain 160 miles home. The bike began to develope

a wobble on the way home. I parked the bike and started riding my Dakar. (I have only bikes now) The '05 FJR sat until curiosity won the day and I decided to try swapping an used tire I

had sitting around. I had never even removed a rear tire from the bike. After purchasing the needed tools, I consulted FJRTECH and performed the swap.

Here are some pics:

The original hole (Plugged)

The damaged Plys inside that caused the wobble (No noticeable damage on outside of tire)

Now when I went to reassemble the tire on the bike, I reversed the procedure. When I got the spacer/washer installed AS I DISASSEMBLED IT, the washer seemed "Misplaced". I consulted

the instructions... I found the washer WAS misplaced. It had been placed between the spacer and the caliper! I pulled the axel and put it where it belonged. Now I am wondering just how long

it had been reversed? I have gone through 2 sets of brakes in the last year, which I thought was due to the IBR and the Haul Rd. Now I am wondering if the washer was misplaced and then

reinstalled incorrectly each time after? I guess I will be taking the time to do the work myself from here on out. The procedure was embarrassingly easy.

Now I have learned some things:

Spooning isn't always fun

Never ride on a flat (Even 2 miles)

Doing your own maintenance is cool (If you have the time)

5 gallon buckets don't make the best tire work stands

Tools, tools, and more tools are needed

Oh, most importantly... a big thanks to the guys that have done the work on the "How to(s)"

Last edited by a moderator:

![fjackets Real Lambskin Leather Biker Jacket — Quilted Cafe Racer Zip Up Moto Leather Jackets For Men | [1100085] Johnson Brown, XL](https://m.media-amazon.com/images/I/41I7Pm1f+vL._SL500_.jpg)