I changed my air filter for the first time and I noticed when putting back all the side panels that the intake seems to be totally blocked. I asked my mechanic at the dealer and he agreed, it is like this to quiet the intake noise. Has anyone tried cutting something on the side covers to aid in letting in some air to the engine.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stiffled Air Intake

- Thread starter harveyfjr

- Start date

Help Support Yamaha FJR Motorcycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

twowheelnut

R.I.P. Our Motorcycling Friend

Ya think the Yamaha engineers missed that detail? Leave them alone. I think Joos screwed around for a long time messin' with the air box to no avail...

Last edited by a moderator:

BrunDog

Well-known member

I agree. Putting holes where they don't belong may add an avenue for water to get ingested.

-BD

-BD

RadioHowie

I Miss Beemerdons!

...and an avenue for all those decibels to get out. Then you could rename your FJR "Hoover".

Toynut

Well-known member

Put it this way.... You'd probably breath easier with a third nostril opening. :bigeyes:

But... It would be quite awful, esthetically speaking, to put one on your face with a 1/2" auger bit, eh? :haha:

Of course, you might try grafting one of those nifty ram air snorkels off of a V-Max onto a FJR.

Now THAT would be a sight to see!! :dribble:

But... It would be quite awful, esthetically speaking, to put one on your face with a 1/2" auger bit, eh? :haha:

Of course, you might try grafting one of those nifty ram air snorkels off of a V-Max onto a FJR.

Now THAT would be a sight to see!! :dribble:

$46.95

Harley Davidson Logo Sport Duffel (Tail of The Dragon), Black, One Size

Wisconsin Harley-Davidson

$22.09

$25.99

MOREOK Waterproof & Windproof -30°F Winter Gloves for Men/Women, 3M Thinsulate Thermal Gloves Touch Screen Warm Gloves for Skiing,Cycling,Motorcycle,Running-Black-L

MOREOK-US (Ships from USA)

$49.00

WILD HEART Waterproof Motorcycle Duffel Bag PVC500D With Rope Straps and Inner Pocket 40L 66L 100L for Kayaking, Camping, Boating,Motorcycle

ZHONGSHAN WILD FRUIT OUTDOOR

$49.99

$54.99

HOOD CREW Men’s Casual Stand Collar PU Faux Leather Zip-Up Motorcycle Bomber Jacket With a Removable Hood

Jamickiki

$15.15

$21.95

Tough Headwear Balaclava Ski Mask - Winter Face Mask for Men & Women - Cold Weather Gear for Skiing, Snowboarding & Motorcycle Riding (Black)

Tough Outfitters

$127.99

$159.99

FLAVOR Men Brown Leather Motorcycle Jacket with Removable Hood (Large (US standard), Brown)

FLAVOR Leather

$64.99

Edwards Oil Change Kit fits 2003-2020 Yamaha FJR1300 Sport Touring

Edwards Motorsports & RV's

$44.99

Real Time Industries Reflective Decals for Yamaha FJR1300 Gen 2 Fairing (Black - Silver Print)

Real Time Industries

$24.37

Fuel Tank Sticker Motorcycle Stickers for Yam&aha FJR1300 FJR 1300 Tank Pad Protector Decal Emblem Side Fairing Symbol Adventure

nanyangshixianpushangmaohanggerenduzi

$22.09

$25.99

MOREOK Waterproof & Windproof -30°F Winter Gloves for Men/Women, 3M Thinsulate Thermal Gloves Touch Screen Warm Gloves for Skiing,Cycling,Motorcycle,Running-Black-XL

MOREOK-US (Ships from USA)

Toynut

Well-known member

Any takers on the last mod suggestion???

Beuler....Beuler??? :huh:

Beuler....Beuler??? :huh:

meosborn

Well-known member

There has been plenty of discussion about the intake on the FJR. I seem to recall that the result was that any sort of intake bottleneck that may exist is after the filter and really beyond the expertise of most of us. But, if you think you can build a better mousetrap, go ahead and I (as well as plenty of others) would be happy to hear the results.

By the way, need a rack for an '03! :erm:

By the way, need a rack for an '03! :erm:

Last edited by a moderator:

yamaholic

Well-known member

I removed this piece a couple of years ago. Slightly more intake noise, but no real increase in power that I could perceive. I run the FJR pretty hard, so I would likely feel a significant change.

The reason for me doing this wasn't for more power. It was to free up air gaps under the seat to allow for the engine heat to escape under the seat as opposed to being blocked and directed outward toward your left knee. Also, it allowed for more efficient underseat storage after you hack/cut the unnecessary plastic.

AFAIF, only me and kidrock did this. We both found less heat transmitted to the left knee/leg.

The reason for me doing this wasn't for more power. It was to free up air gaps under the seat to allow for the engine heat to escape under the seat as opposed to being blocked and directed outward toward your left knee. Also, it allowed for more efficient underseat storage after you hack/cut the unnecessary plastic.

AFAIF, only me and kidrock did this. We both found less heat transmitted to the left knee/leg.

RTSR1/FJR

Gort - Klaatu barada nikto!

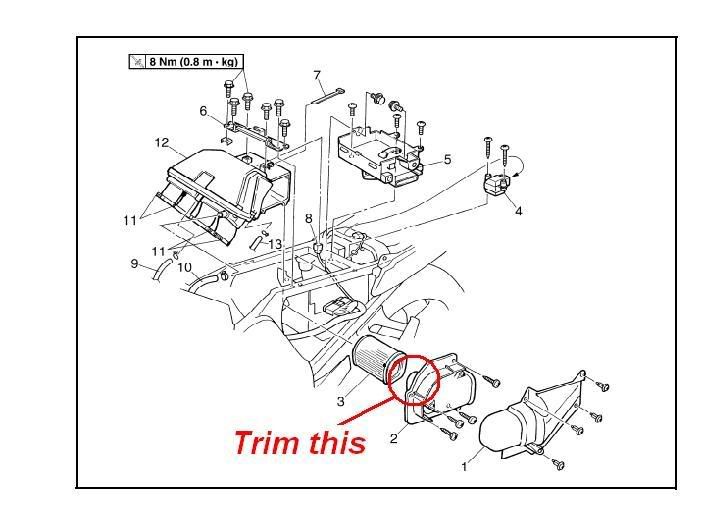

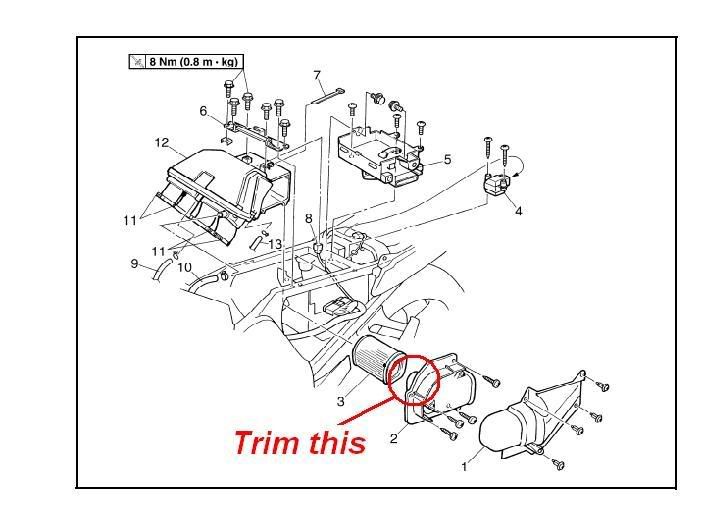

It just looks to me like the cover could be trimmed to allow cylinders 1&2 to breath better without shrouding the filter so much. Trim this piece off on the backside.

Last edited by a moderator:

charismaticmegafauna

Well-known member

RTSR1/FJR, your suggestion looks to have some merit , on first appearance. One of the reasons I prefer to buy factory made motorcycles (instead of building my own) is that some engineer may have done flow studies and dyno tests to determine the optimum size and shape of the air-box. I want to think that all four cylinders breathe from the air-box equally -- but, your suggestion is intruiging. Maybe someone will do it and run some dyno tests? Once proven, it may be a good modification?

Reg# 43897

Well-known member

Ohhhhh, now I get it... Might be right. I wonder.

John.

John.

Howardrg

Well-known member

If You feel that you know more than the author of the following article go ahead and mess with the airbox

Howard

Introduction.

Motorcycles have had air boxes holding their air filters for decades. However, in the last couple of decades the purpose of these air boxes has changed quite dramatically.

Originally the air box was just there to keep flying dirt, rain, and bugs from directly hitting the air cleaner. They were simply an attempt to keep the air cleaner a little cleaner a little longer.

In the '70s, the US government started making noise regulations tighter. At some point, the manufacturers realized that the noise from the air intake was part of their problem. They started to look for ways to muffle not only the exhaust, but the intake roar too. Sound waves are pressure pulses in the air. Pistons pull in air on their intake stroke, creating a low pressure pulse in the air box. Then on the compression, power, and exhaust strokes the intake valve is closed and the air box is free to return to atmospheric pressure. These alternating low pressure and normal pressure pulses are sound waves. The manufacturers needed some way to dampen them out.

Your exhaust mufflers are made of a series of open chambers connected to each other by tubes. The exhaust pressure pulses get caught in the chambers and bounce around in them, then have to leak out relatively slowly through the tubes. The math that governs mufflers can also be applied to air boxes: you need a big chamber to hold a bunch of air, and an inlet tube to let air in at a controlled rate.

The air in a box is compressible, so a box is the acoustic analog of a capacitor or spring. Air has mass - about 1kg / cubic meter, about 2 pounds per cubic yard. In a tube, the air moves back and forth as a slug, as long as the frequency of the movement is small compared to (tube length / speed of sound). So, at low frequencies a tube is a mass term. Since the speed of sound is about 1000 feet per second, a foot long tube is equivalent to 1 khz. 10,000 rpm is 160 pulses per second on a V-Twin, so "low frequency" clearly applies on an air box for any snorkel shorter than about 6 feet long. A wire screen is the acoustic analog of a resistor. It slows air motion, converting the energy into heat. The combination of a box and tube is a system with a resonance. Exactly as a child's swing has a resonant frequency, exactly as a ported speaker enclosure has a resonant frequency, so does your air box.

A system at resonance is nearly perfect - there are small frictional losses in any system, but at resonance these are the only losses. Imagine pushing a child on a swing - it takes very little energy to keep her going at the natural frequency of the swing, just a little push each swing is enough. The only thing slowing her down is air resistance and a little friction in the chains. So at resonance, air flows through a tuned air box almost without resistance. This is as close as we can get to a superconductor of air.

A modern engine with valve overlap will naturally have a dip in the torque at about a third to a half the red line rpm. If the air box is tuned to have minimum resistance to air flow at this rpm, the dip in the torque curve will be partially filled in by the ease of pulling air into the engine.

So, your air box is most likely designed to add horsepower in the mid-range. The air box will have little or no effect on peak hp.

Years ago, before airboxes were designed as resonant systems, it used to be popular to cut additional holes in the air box to allow more air flow for high rpm. This is no longer a good idea. Modern air boxes can flow much more air than the engine will ever use. Modern engines have throttle bodies or carburetors with throats that are typically about 45mm in diameter, about 16 sq.cm in area. The inlet snorkel to a modern air box will be roughly 300 to 800 sq.cm - much larger than the throttle body or carburetor throat. The idea that the snorkel makes for a significant impediment to air flow into the engine is questionable at best. Drilling holes to let in more air is exactly equivalent to drilling holes in your speaker cabinets to let out more sound. Removing the snorkel from your air box is the exact same thing as removing the port in your speakers, the tube that's carefully engineered to have just the right diameter and length to reinforce the bass on your speakers at low frequencies. By altering your air box in any significant fashion, you're most likely going to cost yourself three to five hp in the mid range, and gain nothing measurable at high rpms.

--------------------------------------------------------------------------------

Part I: Theory.

Here, from first principles we'll develop the theory of how an air box and an inlet tube form a coupled spring- mass system with a resonant frequency.

air box volume = V

inlet pipe = area * length = A * L

Air Mass = 1.25g / 1000 cc

Atmospheric Pressure = 104kg / cm sec2

PV = nkT (Ideal Gas Law)

If the air in the inlet tube moves X cm into the air box, then the volume of air inside the air box changes to:

V' = V + AX

Since Boltzman's constant and the air box volume don't change, that leaves only the temperature and the pressure. The gamma for air is 1.4, so

T' / T = (V' / V)^.4

T' / T = (1 + AX/V)^.4

We'll presume AX/V is small, so (1 + AX/V)^.4 = 1 + .4AX/V

The number of atoms in the air box changes to n' = (1 + AX/V)n. So, the new pressure is:

P'V = (1+AX/V) nk (1+.4AX/V) T

P' = (1 + AX/V) (1 + .4AX/V) P

P' = (1 + 1.4 AX/V) P

Now we can find the spring constant of the air box, K:

Force = Pressure*Area = Kx

Kx = 1.4 AX/V * A * 104 kg cm / sec2

K = AA/V * 146 kg / sec2

The mass of air in the inlet tube is

M = AL * 1.25g / 1000

The resonant frequency w, in radians per second, of a spring-mass system is:

w = sqrt( K/M )

= sqrt( AA/V * 146 kg / sec2 * 1000 / 1.25g AL )

= sqrt( A/VL * 146*1000*1000 / 1.25 sec2 )

= 1000 sqrt( 116.5 A/VL ) / sec

The resonant frequency is w / 2pi, and the resonant rpm is 30 * number of cylinders * f. For a V-twin, rpm = 60 * f.

f = w / 2pi = 160 sqrt( 116.5 A / VL )

resonant rpm = 4775 sqrt( 116.5 A / VL ) (single cylinder)

resonant rpm = 9550 sqrt( 116.5 A / VL ) (V-twin)

resonant rpm = 19100 sqrt( 116.5 A / VL ) (4 cylinder)

--------------------------------------------------------------------------------

Part II. Applications.

Here we'll examine a particular design, and see if we can understand the purpose of the design.

On the Suzuki V-Strom, the air box holds approximately 8 liters, about 8000 ccs. There's an inlet pipe which has a 90 degree bend in it. The two sides, inner and outer, differ in length a bit. We'll use their average, the centerline distance, as the length of the pipe. The pipe opening is about 200 square centimeters, and the length is about 20cm. Fortunately, as all these numbers appear inside a square root, our results will not depend on highly accurate measurements. Of course, if you're designing an air box you would want to be quite precise, but we're just trying to understand an existing design, so if we're off by a few percent it won't really matter. We'll also concern ourselves with the flow through the pipe and see if the mach number of the airflow is low enough to ensure linearity.

At 12,000 rpm, the V-Strom's 1 liter motor is pumping 6,000 liters per minute, 100 liters per second. The V- Strom inlet snorkel has an opening of about 200 cm2. 100 liters per second is a column of air 1000 cm 2 wide by 10 meters long, or 200 cm 2 * 50 meters long, so apparently the peak velocity through the inlet tube is less than 50 meters per second. The speed of sound at sea level is about 340 meters per second, so this is about mach .14.

Whenever air flows past something, like the walls of the inlet snorkel, the air touching the walls will stick to the walls and not flow. The air very close to the stuck air will flow, but sluggishly because the nearby air isn't moving. Thus there will be a region of air right next to the tube walls which does not flow easily. This area is called the Poisson stagnation region, named after the French physicist who first described it mathematically. The faster you try to flow air through the tube, the thicker the stagnation region gets. In a narrow tube at extremely high flow rates, the stagnation regions can grow to pretty much fill the tube and the flow through the tube can get slowed quite dramatically. However, mach .14 is not a very high flow rate. This low peak velocity guarantees the Poisson stagnation region on the tube walls will remain thin, and the tube will be substantially open for free flow. We've satisfied the engineers's prayer "Please, God, let it be linear."

The resonant rpm will be 9550 * sqrt( 116.5 A / VL ) = 9550 * sqrt( 116.5*200 / 8000*20 ) = 9550 * sqrt ( 116.5 / 800 ) = 9550 * .38 = 3650 rpm

This number is consistent with the torque dip in a 10,000 rpm v-twin with valve overlap. Remember, we only estimated the volume of the air box and the length and width of the snorkel, so 3650 rpm is just an estimate and is most likely off by a few hundred rpm. Apparently the Suzuki engineers designed an air box which would resonate at the torque dip, thereby giving essentially frictionless airflow at the rpm where the engine was having the most trouble making torque.

If you decided to make substantial modifications to your engine, like high compression pistons, new cam shafts, and re-mapped ignition and fuel injection, you would very likely change the rpm at which the mid-range torque dip happens. In this case, if you can measure the new rpm on a dyno, you could use this information and our formula to decide on a new snorkel length to change the air box resonance to match the new torque dip.

--------------------------------------------------------------------------------

Howard

Introduction.

Motorcycles have had air boxes holding their air filters for decades. However, in the last couple of decades the purpose of these air boxes has changed quite dramatically.

Originally the air box was just there to keep flying dirt, rain, and bugs from directly hitting the air cleaner. They were simply an attempt to keep the air cleaner a little cleaner a little longer.

In the '70s, the US government started making noise regulations tighter. At some point, the manufacturers realized that the noise from the air intake was part of their problem. They started to look for ways to muffle not only the exhaust, but the intake roar too. Sound waves are pressure pulses in the air. Pistons pull in air on their intake stroke, creating a low pressure pulse in the air box. Then on the compression, power, and exhaust strokes the intake valve is closed and the air box is free to return to atmospheric pressure. These alternating low pressure and normal pressure pulses are sound waves. The manufacturers needed some way to dampen them out.

Your exhaust mufflers are made of a series of open chambers connected to each other by tubes. The exhaust pressure pulses get caught in the chambers and bounce around in them, then have to leak out relatively slowly through the tubes. The math that governs mufflers can also be applied to air boxes: you need a big chamber to hold a bunch of air, and an inlet tube to let air in at a controlled rate.

The air in a box is compressible, so a box is the acoustic analog of a capacitor or spring. Air has mass - about 1kg / cubic meter, about 2 pounds per cubic yard. In a tube, the air moves back and forth as a slug, as long as the frequency of the movement is small compared to (tube length / speed of sound). So, at low frequencies a tube is a mass term. Since the speed of sound is about 1000 feet per second, a foot long tube is equivalent to 1 khz. 10,000 rpm is 160 pulses per second on a V-Twin, so "low frequency" clearly applies on an air box for any snorkel shorter than about 6 feet long. A wire screen is the acoustic analog of a resistor. It slows air motion, converting the energy into heat. The combination of a box and tube is a system with a resonance. Exactly as a child's swing has a resonant frequency, exactly as a ported speaker enclosure has a resonant frequency, so does your air box.

A system at resonance is nearly perfect - there are small frictional losses in any system, but at resonance these are the only losses. Imagine pushing a child on a swing - it takes very little energy to keep her going at the natural frequency of the swing, just a little push each swing is enough. The only thing slowing her down is air resistance and a little friction in the chains. So at resonance, air flows through a tuned air box almost without resistance. This is as close as we can get to a superconductor of air.

A modern engine with valve overlap will naturally have a dip in the torque at about a third to a half the red line rpm. If the air box is tuned to have minimum resistance to air flow at this rpm, the dip in the torque curve will be partially filled in by the ease of pulling air into the engine.

So, your air box is most likely designed to add horsepower in the mid-range. The air box will have little or no effect on peak hp.

Years ago, before airboxes were designed as resonant systems, it used to be popular to cut additional holes in the air box to allow more air flow for high rpm. This is no longer a good idea. Modern air boxes can flow much more air than the engine will ever use. Modern engines have throttle bodies or carburetors with throats that are typically about 45mm in diameter, about 16 sq.cm in area. The inlet snorkel to a modern air box will be roughly 300 to 800 sq.cm - much larger than the throttle body or carburetor throat. The idea that the snorkel makes for a significant impediment to air flow into the engine is questionable at best. Drilling holes to let in more air is exactly equivalent to drilling holes in your speaker cabinets to let out more sound. Removing the snorkel from your air box is the exact same thing as removing the port in your speakers, the tube that's carefully engineered to have just the right diameter and length to reinforce the bass on your speakers at low frequencies. By altering your air box in any significant fashion, you're most likely going to cost yourself three to five hp in the mid range, and gain nothing measurable at high rpms.

--------------------------------------------------------------------------------

Part I: Theory.

Here, from first principles we'll develop the theory of how an air box and an inlet tube form a coupled spring- mass system with a resonant frequency.

air box volume = V

inlet pipe = area * length = A * L

Air Mass = 1.25g / 1000 cc

Atmospheric Pressure = 104kg / cm sec2

PV = nkT (Ideal Gas Law)

If the air in the inlet tube moves X cm into the air box, then the volume of air inside the air box changes to:

V' = V + AX

Since Boltzman's constant and the air box volume don't change, that leaves only the temperature and the pressure. The gamma for air is 1.4, so

T' / T = (V' / V)^.4

T' / T = (1 + AX/V)^.4

We'll presume AX/V is small, so (1 + AX/V)^.4 = 1 + .4AX/V

The number of atoms in the air box changes to n' = (1 + AX/V)n. So, the new pressure is:

P'V = (1+AX/V) nk (1+.4AX/V) T

P' = (1 + AX/V) (1 + .4AX/V) P

P' = (1 + 1.4 AX/V) P

Now we can find the spring constant of the air box, K:

Force = Pressure*Area = Kx

Kx = 1.4 AX/V * A * 104 kg cm / sec2

K = AA/V * 146 kg / sec2

The mass of air in the inlet tube is

M = AL * 1.25g / 1000

The resonant frequency w, in radians per second, of a spring-mass system is:

w = sqrt( K/M )

= sqrt( AA/V * 146 kg / sec2 * 1000 / 1.25g AL )

= sqrt( A/VL * 146*1000*1000 / 1.25 sec2 )

= 1000 sqrt( 116.5 A/VL ) / sec

The resonant frequency is w / 2pi, and the resonant rpm is 30 * number of cylinders * f. For a V-twin, rpm = 60 * f.

f = w / 2pi = 160 sqrt( 116.5 A / VL )

resonant rpm = 4775 sqrt( 116.5 A / VL ) (single cylinder)

resonant rpm = 9550 sqrt( 116.5 A / VL ) (V-twin)

resonant rpm = 19100 sqrt( 116.5 A / VL ) (4 cylinder)

--------------------------------------------------------------------------------

Part II. Applications.

Here we'll examine a particular design, and see if we can understand the purpose of the design.

On the Suzuki V-Strom, the air box holds approximately 8 liters, about 8000 ccs. There's an inlet pipe which has a 90 degree bend in it. The two sides, inner and outer, differ in length a bit. We'll use their average, the centerline distance, as the length of the pipe. The pipe opening is about 200 square centimeters, and the length is about 20cm. Fortunately, as all these numbers appear inside a square root, our results will not depend on highly accurate measurements. Of course, if you're designing an air box you would want to be quite precise, but we're just trying to understand an existing design, so if we're off by a few percent it won't really matter. We'll also concern ourselves with the flow through the pipe and see if the mach number of the airflow is low enough to ensure linearity.

At 12,000 rpm, the V-Strom's 1 liter motor is pumping 6,000 liters per minute, 100 liters per second. The V- Strom inlet snorkel has an opening of about 200 cm2. 100 liters per second is a column of air 1000 cm 2 wide by 10 meters long, or 200 cm 2 * 50 meters long, so apparently the peak velocity through the inlet tube is less than 50 meters per second. The speed of sound at sea level is about 340 meters per second, so this is about mach .14.

Whenever air flows past something, like the walls of the inlet snorkel, the air touching the walls will stick to the walls and not flow. The air very close to the stuck air will flow, but sluggishly because the nearby air isn't moving. Thus there will be a region of air right next to the tube walls which does not flow easily. This area is called the Poisson stagnation region, named after the French physicist who first described it mathematically. The faster you try to flow air through the tube, the thicker the stagnation region gets. In a narrow tube at extremely high flow rates, the stagnation regions can grow to pretty much fill the tube and the flow through the tube can get slowed quite dramatically. However, mach .14 is not a very high flow rate. This low peak velocity guarantees the Poisson stagnation region on the tube walls will remain thin, and the tube will be substantially open for free flow. We've satisfied the engineers's prayer "Please, God, let it be linear."

The resonant rpm will be 9550 * sqrt( 116.5 A / VL ) = 9550 * sqrt( 116.5*200 / 8000*20 ) = 9550 * sqrt ( 116.5 / 800 ) = 9550 * .38 = 3650 rpm

This number is consistent with the torque dip in a 10,000 rpm v-twin with valve overlap. Remember, we only estimated the volume of the air box and the length and width of the snorkel, so 3650 rpm is just an estimate and is most likely off by a few hundred rpm. Apparently the Suzuki engineers designed an air box which would resonate at the torque dip, thereby giving essentially frictionless airflow at the rpm where the engine was having the most trouble making torque.

If you decided to make substantial modifications to your engine, like high compression pistons, new cam shafts, and re-mapped ignition and fuel injection, you would very likely change the rpm at which the mid-range torque dip happens. In this case, if you can measure the new rpm on a dyno, you could use this information and our formula to decide on a new snorkel length to change the air box resonance to match the new torque dip.

--------------------------------------------------------------------------------

slapnpop

Rest in Peace our Forum Founder

Why does resonance mean perfect air flow?

Resonance occurs when a sound wave is the proper frequency for the volume and shape to establish a standing wave. (shape is a VERY important part of this equation, with overall length being a more important factor than diameter)

In an engine these two are indeed tied together, but the flow rate is determined by displacement too, so every Vtwin isn't going to have the same resonance frequency/airflow intersection.

At any rate, what does the intake pressure resonance have to do with the flowrate? What would the difference in negative pressure required for a given flowrate do with a varying resonance frequency?

I'm not saying they aren't, I just don't understand how they are. I also didn't see this part in your article above.

Resonance occurs when a sound wave is the proper frequency for the volume and shape to establish a standing wave. (shape is a VERY important part of this equation, with overall length being a more important factor than diameter)

In an engine these two are indeed tied together, but the flow rate is determined by displacement too, so every Vtwin isn't going to have the same resonance frequency/airflow intersection.

At any rate, what does the intake pressure resonance have to do with the flowrate? What would the difference in negative pressure required for a given flowrate do with a varying resonance frequency?

I'm not saying they aren't, I just don't understand how they are. I also didn't see this part in your article above.

HIGHLANDER

naewittyshitepostedeere

TWN is correct !Ya think the Yamaha engineers missed that detail? Leave them alone. I think Joos screwed around for a long time messin' with the air box to no avail...

Joos and staff ( bikejohnny ) played with the airbox for months trying to redesign / modify the airbox. After months of trying / designing / dyno tests it was decided there was nothing to gain trying to modify what the jap engineers already designed for the FJR

MCRIDER007

Well-known member

I think what Joos and staff demonstrated was that the FJR's airbox delivers as much air as required to the FJR's engine in its current configuration. The FJR currently makes about 100 rear wheel HP per liter, which is almost mild in comparison for the 150+ HP per liter being generated by the late model sport bikes. If Yamaha or anyone else wanted to boost the FJR's HP (with hotter cams, higher compression pistons, larger valves, or a redesigned combustion chamber) then they are also going to have to redesign the airbox to flow more air but until then there is not any reason to modify the airbox.Joos and staff ( bikejohnny ) played with the airbox for months trying to redesign / modify the airbox. After months of trying / designing / dyno tests it was decided there was nothing to gain trying to modify what the jap engineers already designed for the FJR

Howardrg

Well-known member

Air flow follows the same basic laws as all other flows, including water and electricity. There is an analog to resistance for air flow, it's the coefficient of drag. However, here we're talking about something which is more like AC current, not DC current - a car going a constant 60 mph is more like DC current. Anyway, for AC circuits there are also resonance's, and at certain resonance the resistance is a minimum.

For example, nearly all electric motors, which are basically large inductors, have capacitors attached to them to resonate out the impedance. This is why large factories have large capacitors buried outside at the power terminals.

The frequency in the air box is proportional to the RPM. The inductance is made by the inlet tubes. The capacitance is made by the air box volume. By carefully selecting tube length and width and box volume, we can make the air flow at a particular RPM be nearly perfect.

Even though the air is pulsing at the motor inlet valves, it's a smooth constant flow at the tube inlet.

Should you alter in any way the air box size, drill holes, shorten the intake tube or do any modification, you will possibly do more harm than good. This is to say on modern Motorcycles. Air box design is a science in itself.

Sorry, I know this is very hand waving and probably not very satisfying. The real topic is handled in about a junior or senior course in electrical engineering, and involves complex numbers and LaPlace transforms, which is the complex analog of the Fourier transform.

None of this is very intuitive because in our normal lives everything we're accustomed to working with is DC flow - water in a hose, air from a fan, power from a battery. The only place we see this in our day to day lives is in speaker cabinets, which have a carefully selected box volume and normally a port of carefully selected width and length. The math is pretty much identical to the air box maths

Hope this helps

Howard

For example, nearly all electric motors, which are basically large inductors, have capacitors attached to them to resonate out the impedance. This is why large factories have large capacitors buried outside at the power terminals.

The frequency in the air box is proportional to the RPM. The inductance is made by the inlet tubes. The capacitance is made by the air box volume. By carefully selecting tube length and width and box volume, we can make the air flow at a particular RPM be nearly perfect.

Even though the air is pulsing at the motor inlet valves, it's a smooth constant flow at the tube inlet.

Should you alter in any way the air box size, drill holes, shorten the intake tube or do any modification, you will possibly do more harm than good. This is to say on modern Motorcycles. Air box design is a science in itself.

Sorry, I know this is very hand waving and probably not very satisfying. The real topic is handled in about a junior or senior course in electrical engineering, and involves complex numbers and LaPlace transforms, which is the complex analog of the Fourier transform.

None of this is very intuitive because in our normal lives everything we're accustomed to working with is DC flow - water in a hose, air from a fan, power from a battery. The only place we see this in our day to day lives is in speaker cabinets, which have a carefully selected box volume and normally a port of carefully selected width and length. The math is pretty much identical to the air box maths

Hope this helps

Howard

zorkler

Ave U !!!!

nice stuff . but it does not work on my 1975 z1 900 . wow have we come a long way

Similar threads

- Replies

- 2

- Views

- 529

- Replies

- 10

- Views

- 843

- Replies

- 23

- Views

- 3K