wfooshee

O, Woe is me!!

From my recent findings in my transmission, which I never would have found had the weld not broken on my star cam, I have formed some opinions about the common "fix" of undercutting the dogs to keep a gear from being able to jump out.

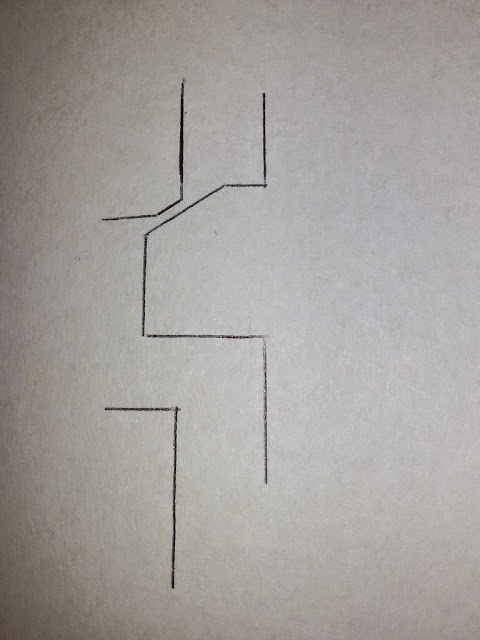

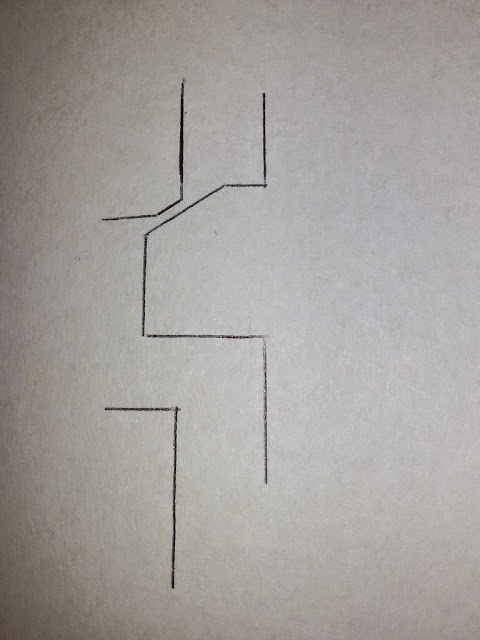

The issue is that the engaging surfaces of the dogs exhibit wear over time, and the corners round off or even form an angle. Here's a diagram of what I found on my 4th-gear set. The wheel with the dog pins is on the right, and moves to the left to engage 4th gear. That gear has holes in its wheel to accept the dog pins. On mine there was severe wear showing an angle on both the dogs and the edges of the holes.

The effect of that angle is the production of an axial force to the right, resisted only by the shift fork. The result of that was:

It's a self-feeding failure, as the worn shift fork means that the 4th gear engagement gets weaker and weaker over time, using less and less of the surface of the dog pins, wearing them down harder and creating more axial force into the shift fork, wearing the shift fork even more, ad infinitum.

I had the issue on 2nd gear as well, enough so that I had the second gear skip issue that's been discussed several times elsewhere, and that's what made me decide to actually go into the transmission when this happened, rather than just replace the shift drum where the star cam broke. My 2nd gear showed similar wear but nowhere near this bad. In use, 4th gear never skipped or jumped out of gear, but I got a false neutral when shifting to 4th several times. Another thing that just feeds the wear rate.....

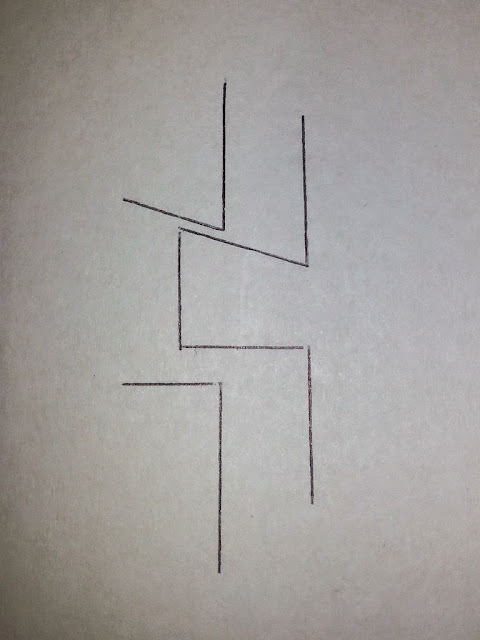

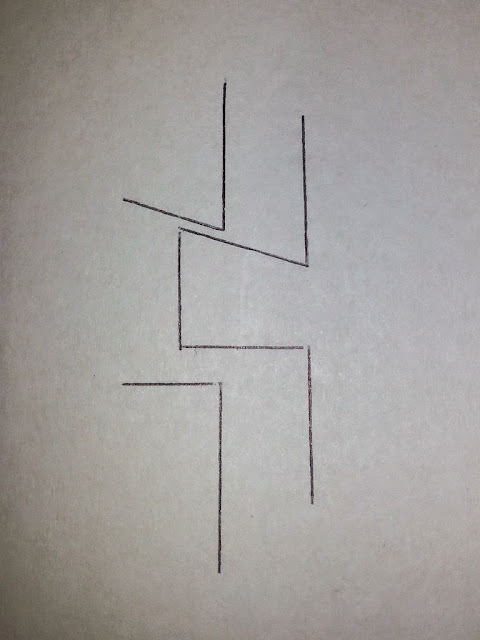

So the "common wisdom" is to either machine the dogs on the parts, or get new parts and machine those, so that an angle is intentionally placed the other direction, effectively locking the engagement while under thrust. Quick-and-dirty diagram:

Now the angled cut of the dogs pulls the wheels together, preventing skipping and jumping out of gear. Eureka!!!

But wait...... hold on a minute there........

When a gear is engaged, those facing surfaces of adjacent wheels don't actually touch. There is still space between the wheels, and the only touchy-feelie parts is where the dogs and holes mate. Undercutting the dogs will pull the sliding wheel towards the other wheel, as intended, but what stops that axial movement first? Do the wheels touch, or does the moving wheel run against the shift fork first and start grinding there????? Basically the same issue I had but on the opposite side of the fork.

Motorcycle transmissions are extraordinarily simply things, mechanically speaking. Compared to manual car transmissions there are no synchronizer rings, the dogs are on the gear wheels themselves rather than separate collars, the gears are straight-cut so there are no thrust bearings needed.

That last piece is the problem. When you undercut the dogs, you introduce axial force on the shaft and something has to become a thrust bearing. It's probably going to be a shift fork.

The issue is that the engaging surfaces of the dogs exhibit wear over time, and the corners round off or even form an angle. Here's a diagram of what I found on my 4th-gear set. The wheel with the dog pins is on the right, and moves to the left to engage 4th gear. That gear has holes in its wheel to accept the dog pins. On mine there was severe wear showing an angle on both the dogs and the edges of the holes.

The effect of that angle is the production of an axial force to the right, resisted only by the shift fork. The result of that was:

It's a self-feeding failure, as the worn shift fork means that the 4th gear engagement gets weaker and weaker over time, using less and less of the surface of the dog pins, wearing them down harder and creating more axial force into the shift fork, wearing the shift fork even more, ad infinitum.

I had the issue on 2nd gear as well, enough so that I had the second gear skip issue that's been discussed several times elsewhere, and that's what made me decide to actually go into the transmission when this happened, rather than just replace the shift drum where the star cam broke. My 2nd gear showed similar wear but nowhere near this bad. In use, 4th gear never skipped or jumped out of gear, but I got a false neutral when shifting to 4th several times. Another thing that just feeds the wear rate.....

So the "common wisdom" is to either machine the dogs on the parts, or get new parts and machine those, so that an angle is intentionally placed the other direction, effectively locking the engagement while under thrust. Quick-and-dirty diagram:

Now the angled cut of the dogs pulls the wheels together, preventing skipping and jumping out of gear. Eureka!!!

But wait...... hold on a minute there........

When a gear is engaged, those facing surfaces of adjacent wheels don't actually touch. There is still space between the wheels, and the only touchy-feelie parts is where the dogs and holes mate. Undercutting the dogs will pull the sliding wheel towards the other wheel, as intended, but what stops that axial movement first? Do the wheels touch, or does the moving wheel run against the shift fork first and start grinding there????? Basically the same issue I had but on the opposite side of the fork.

Motorcycle transmissions are extraordinarily simply things, mechanically speaking. Compared to manual car transmissions there are no synchronizer rings, the dogs are on the gear wheels themselves rather than separate collars, the gears are straight-cut so there are no thrust bearings needed.

That last piece is the problem. When you undercut the dogs, you introduce axial force on the shaft and something has to become a thrust bearing. It's probably going to be a shift fork.

Last edited by a moderator: