After hearing about ionbeam and Radiohowie, I thought for a few $$ I'm going to replace my CCT. My 2005 has over 43K on it and I've suspected CC noise from the CCT being not so robust, for the $$ why not try it.

***EDIT***The engine is now much quieter, my hunch on the noise being the CCT was correct. I'm glad I changed it.

**EDIT** 5/14/11 Other issues I ran into this time around. The lower bolt did not work well with my ratchet wrench. I had to resort to my cut 8mm socket and wobble extension, that did the trick this time. I guess not every Feej is alike. It was real easy again and much quicker since I know what I’m doing. My old CCT was weaker in the resistance department. Glad I changed it. Also it is more quite again.

I ordered all my OEM parts from mrcycles.com CCT $71, gasket about $1.70.

There are many threads on CCT issues etc, I followed this CCT thread (page two has some great pix too) and wanted to add to it, like a CCT change for dummies. I did not have the same removal/installation luck as the others and did things slightly differently.

Some other Tools to have on hand:

1. Long (3-3/4 or longer) very thin narrow blade screw driver, for retracting CCT plunger.

2. 8mm box end ratcheting wrench (your new best friend).

3. Standard 8mm box end wrench.

4. Your 1/4 inch wobble extension or wobble 8mm socket.

5. Gum.

6. Pencil thick telescoping magnet (another new best friend).

Important Hints & Notes:

1) READ THIS FIRST! **Edit** 9-11-10 (thank you HaulinAshe)

Edit 5/14/11 NOTE:1a) I just did my second CCT removal/install (I bought another 2005 FJR this time with ABS). I did the same stuff as before except.. I took haulinasche's suggestion and secured the cam chain. I removed the stator cover and tied the cam chain across both front and rear so the chain was squeezed by the tie wrap above the crank sprocket, as close to center as I could. I also used a socket as shown in this thread by others as backup if the tie wrap let go. I can now see how it could move and possibly jump a tooth. With everything off and retracting the CCT I could see the slack coming. It still has quite a ways to go, but I guess it’s possible. I absolutely recommend doing this to help prevent any aggravation. The gasket for the stator cover was under $4, not much more time for peace of mind.

2) When you feed the 1/4 extension into the hole in the frame you'll have to put your socket on after the extension is inserted thru the hole. Try not to drop it in a nasty place. I used foil to cover areas I wanted stuff to stay out of. I did drop two bolts and two sockets into the frame hole. Easily retrieved them with my small telescoping magnet device you could get at any Kragen or Harbor Freight.

3) Make sure the ratcheting wrench has a very thin wall on the box end side. If there is too much meat on it, it'll interfere with the CCT. The one in the picture does work. Other brands maybe too thick. I did buy an aftermarket brand on ebay and it worked fine also. I made sure it was a thin ring on the box ends before I bought it, and confirmed on my old one that it fit. <b>DO NOT</b> use the ratchet wrench to initially break loose the bolt, you may break the ratcheting feature of the wrench. Use a standard box end first to break the bolts loose.

Remove this connector and feed the forward (engine) side down thru the frame and let it hang there.

There was no way in HELL the CCT was coming out the top without removing part or the whole throttle body, I tried. It did however, come out thru the bottom like a greased pig, no issues, after removing the idle screw and bracket.

Remove this bolt for the idle adjuster and move the cable and bracket forward on the tranny/engine, make sure you can still retrieve it.

**EDIT** 2/4/12 Read posts #66, page 4. I'm posting this from my post #68, page 4. Thank you TomInCA!

**EDIT** 2/4/12 Read posts #66, page 4. I'm posting this from my post #68, page 4. Thank you TomInCA!

Remove the clutch cover (the big silver thing my finger is on in the photo above) per Tom's post. Much easier access to the lower bolt. Easy peasy, about 10 bolts (I didn't count) and it came right off. Like Tom mentioned no oil came out at all, the clutch is not sitting in a bath of oil like the old days, it's only getting splashed with oil. That would explain sticky clutch plates and why they don't loosen up after just sitting.

NOTE: EXTREME CAUTION! With the clutch cover off, you also have direct access to the lower end connecting rod and crank. This area leads right down to the bottom of the engine case. If anything falls in, YOU’RE HOSED!

Make sure you cover the area with something so NOTHING falls in there, we used foil, worked great.

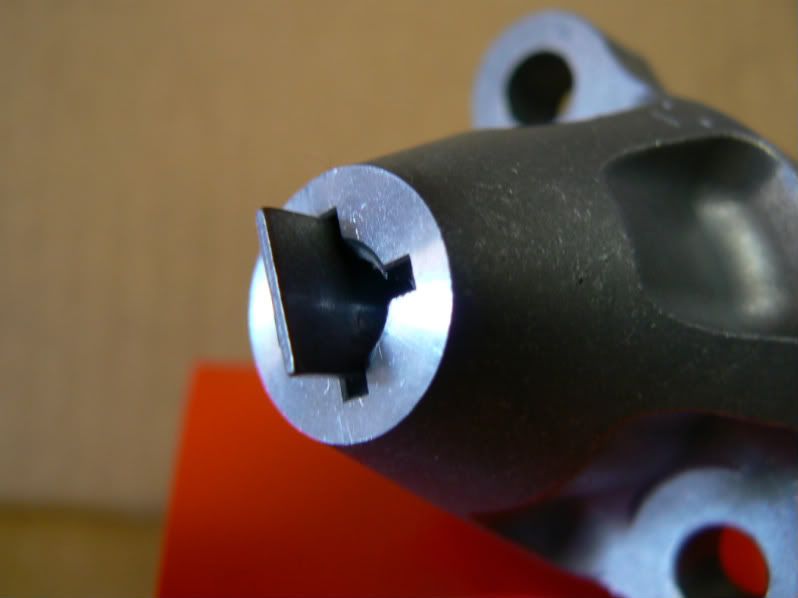

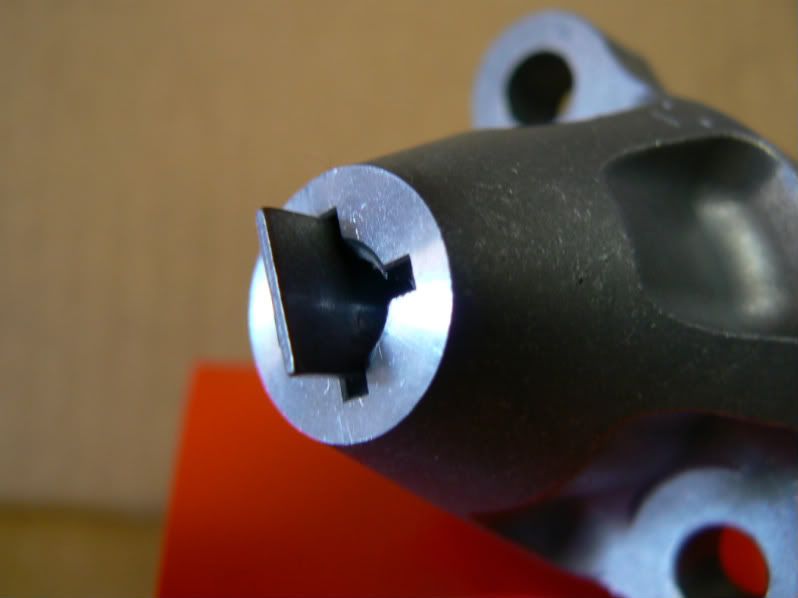

The new CCT comes with the bolt in the middle, and washer. The great thing is the CCT is already retracted and a cool little "T" like device is used as a lock to keep it that way. Let me tell you, excellent idea, made installation a breeze. I actuated the new CCT to feel the resistance, it was very good compared to mine. Mine was not bad but, it was not as good as the new one, I'd say it lost almost half (I'm guessing here) it's spring tension.

Make sure the CCT is installed with the arrow UP and the blue dot UP. The CCT gasket also has a tit on it that lines up with the arrow facing up. The gasket is not symmetrical.

I had a wobble extension and it did NOT work for me, what a PITA. I even modified it by cutting the 8mm socket in half to shorten it, no dice. The hole in the frame was too restrictive and I could not get it even close on the top and the bottom was closer but not good…I would say get this tool and you'll have no issues with funky tool modifying etc.

I used on the upper and lower bolt a trusty Craftsmen box end 8mm, BAM! Cracked it loose no issues. The top was easy once cracked and loosened it by fingers no sweat. I left the upper bolt in just after the crack loose, made sure it spun by hand, then let it be. The bottom I attacked it from the underside and I did get the little extension to partly work and it loosened it enough to get my fingers on it and that bolt came right out too. Leaving the upper bolt in (not tight, just a turn or so out) prevented the CCT from backing out and putting pressure on the lower bolt. I then went back up top and took out the upper bolt. I borrowed my neighbors Craftsmen ratcheting box end it was a dream for installing the lower bolt! Use it on removal too, it'll help huge.

I used gum (as mentioned from previous thread) to help keep the bolt in the middle of the CCT on the socket for removal and installation.

Turn the old CCT internal screw CW (clockwise) all the way and it should lock into that position, this will make it easier to remove the bolts by hand. Once the CCT is free, feed it out the bottom like the pictures show, easy.

This pix shows the CCT fully extended when removing.

Installation is just the reverse.

After CCT installation I pulled the little "T" holder with a long angled pair of needle nose pliers. I then used the screw driver to turn the internal screw CW to retract the plunger and feel the resistance to make sure the CCT extended, it did. If it doesn't extend, slightly turn it CCW to get it to extend (it could be locked closed), then retract it and do it again to make sure it's working.

Some other tricks I did are use Vaseline to keep gasket on CCT during installation.

Good luck, I hope this helps all ya'll who attempt it.

***EDIT***The engine is now much quieter, my hunch on the noise being the CCT was correct. I'm glad I changed it.

**EDIT** 5/14/11 Other issues I ran into this time around. The lower bolt did not work well with my ratchet wrench. I had to resort to my cut 8mm socket and wobble extension, that did the trick this time. I guess not every Feej is alike. It was real easy again and much quicker since I know what I’m doing. My old CCT was weaker in the resistance department. Glad I changed it. Also it is more quite again.

I ordered all my OEM parts from mrcycles.com CCT $71, gasket about $1.70.

There are many threads on CCT issues etc, I followed this CCT thread (page two has some great pix too) and wanted to add to it, like a CCT change for dummies. I did not have the same removal/installation luck as the others and did things slightly differently.

Some other Tools to have on hand:

1. Long (3-3/4 or longer) very thin narrow blade screw driver, for retracting CCT plunger.

2. 8mm box end ratcheting wrench (your new best friend).

3. Standard 8mm box end wrench.

4. Your 1/4 inch wobble extension or wobble 8mm socket.

5. Gum.

6. Pencil thick telescoping magnet (another new best friend).

Important Hints & Notes:

1) READ THIS FIRST! **Edit** 9-11-10 (thank you HaulinAshe)

Edit 5/14/11 NOTE:1a) I just did my second CCT removal/install (I bought another 2005 FJR this time with ABS). I did the same stuff as before except.. I took haulinasche's suggestion and secured the cam chain. I removed the stator cover and tied the cam chain across both front and rear so the chain was squeezed by the tie wrap above the crank sprocket, as close to center as I could. I also used a socket as shown in this thread by others as backup if the tie wrap let go. I can now see how it could move and possibly jump a tooth. With everything off and retracting the CCT I could see the slack coming. It still has quite a ways to go, but I guess it’s possible. I absolutely recommend doing this to help prevent any aggravation. The gasket for the stator cover was under $4, not much more time for peace of mind.

2) When you feed the 1/4 extension into the hole in the frame you'll have to put your socket on after the extension is inserted thru the hole. Try not to drop it in a nasty place. I used foil to cover areas I wanted stuff to stay out of. I did drop two bolts and two sockets into the frame hole. Easily retrieved them with my small telescoping magnet device you could get at any Kragen or Harbor Freight.

3) Make sure the ratcheting wrench has a very thin wall on the box end side. If there is too much meat on it, it'll interfere with the CCT. The one in the picture does work. Other brands maybe too thick. I did buy an aftermarket brand on ebay and it worked fine also. I made sure it was a thin ring on the box ends before I bought it, and confirmed on my old one that it fit. <b>DO NOT</b> use the ratchet wrench to initially break loose the bolt, you may break the ratcheting feature of the wrench. Use a standard box end first to break the bolts loose.

Remove this connector and feed the forward (engine) side down thru the frame and let it hang there.

There was no way in HELL the CCT was coming out the top without removing part or the whole throttle body, I tried. It did however, come out thru the bottom like a greased pig, no issues, after removing the idle screw and bracket.

Remove this bolt for the idle adjuster and move the cable and bracket forward on the tranny/engine, make sure you can still retrieve it.

Remove the clutch cover (the big silver thing my finger is on in the photo above) per Tom's post. Much easier access to the lower bolt. Easy peasy, about 10 bolts (I didn't count) and it came right off. Like Tom mentioned no oil came out at all, the clutch is not sitting in a bath of oil like the old days, it's only getting splashed with oil. That would explain sticky clutch plates and why they don't loosen up after just sitting.

NOTE: EXTREME CAUTION! With the clutch cover off, you also have direct access to the lower end connecting rod and crank. This area leads right down to the bottom of the engine case. If anything falls in, YOU’RE HOSED!

Make sure you cover the area with something so NOTHING falls in there, we used foil, worked great.

The new CCT comes with the bolt in the middle, and washer. The great thing is the CCT is already retracted and a cool little "T" like device is used as a lock to keep it that way. Let me tell you, excellent idea, made installation a breeze. I actuated the new CCT to feel the resistance, it was very good compared to mine. Mine was not bad but, it was not as good as the new one, I'd say it lost almost half (I'm guessing here) it's spring tension.

Make sure the CCT is installed with the arrow UP and the blue dot UP. The CCT gasket also has a tit on it that lines up with the arrow facing up. The gasket is not symmetrical.

I had a wobble extension and it did NOT work for me, what a PITA. I even modified it by cutting the 8mm socket in half to shorten it, no dice. The hole in the frame was too restrictive and I could not get it even close on the top and the bottom was closer but not good…I would say get this tool and you'll have no issues with funky tool modifying etc.

I used on the upper and lower bolt a trusty Craftsmen box end 8mm, BAM! Cracked it loose no issues. The top was easy once cracked and loosened it by fingers no sweat. I left the upper bolt in just after the crack loose, made sure it spun by hand, then let it be. The bottom I attacked it from the underside and I did get the little extension to partly work and it loosened it enough to get my fingers on it and that bolt came right out too. Leaving the upper bolt in (not tight, just a turn or so out) prevented the CCT from backing out and putting pressure on the lower bolt. I then went back up top and took out the upper bolt. I borrowed my neighbors Craftsmen ratcheting box end it was a dream for installing the lower bolt! Use it on removal too, it'll help huge.

I used gum (as mentioned from previous thread) to help keep the bolt in the middle of the CCT on the socket for removal and installation.

Turn the old CCT internal screw CW (clockwise) all the way and it should lock into that position, this will make it easier to remove the bolts by hand. Once the CCT is free, feed it out the bottom like the pictures show, easy.

This pix shows the CCT fully extended when removing.

Installation is just the reverse.

After CCT installation I pulled the little "T" holder with a long angled pair of needle nose pliers. I then used the screw driver to turn the internal screw CW to retract the plunger and feel the resistance to make sure the CCT extended, it did. If it doesn't extend, slightly turn it CCW to get it to extend (it could be locked closed), then retract it and do it again to make sure it's working.

Some other tricks I did are use Vaseline to keep gasket on CCT during installation.

Good luck, I hope this helps all ya'll who attempt it.

Last edited by a moderator: