7/6/2015 - It has been reported that reading all of the comments and discussion in the replies to this thread can be a bit confusing. All of the information required to perform the RDCUA TBS procedure is contained in this first post, or at the procedure linked to immediately below. This post has been updated to reflect the best working procedure for first and second gen FJRs.

(note that the RDCUA TBS cannot be performed on 3rd Gen FJRs)

3/2013 - I have captured and compiled a complete html version of this procedure and am hosting t at my fjr.nerds web space for posterity here: The Really, Definitely, Completely Un-Authorized Throttle Body Sync (TBS)

Re-edited 10/2012

This version of the UnAuthorized TBS procedure is based on a premise; that the ideal throttle synchronization is when the throttle plates are aligned with each other and parallel.

After a large number of uses, this procedure has been found to be very effective. Nobody who has used this procedure has ever said that it made their bike run worse. Most people say that their bike ran smoother (less vibration at ~4k-5k rpm ranges.

You will see some discussion in other posts about alternate ways to adjust the throttle plates. Some folks believe that you need to rev the engine. Some think that you need to load the engine and rev it. None of these other methods have been shown to be any more effective than doing it the way detailed here. And this way is a lot easier to do.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

For those just tuning in, what's going on here is that the "official" throttle body sync procedure, the one called out in the Factory Service Manual (FSM) and specified as a "required" procedure at 4k mi. intervals (what?) is simply an adjustment of the air bypass screws at idle speed. These bypass screws have their primary effect on vacuum at idle speed, and have very little to do with how smoothly the engine runs at anything other than at idle or just above. As the throttle butterfly plates open, the tiny amount of air contributed to the total intake by the bypass circuit becomes increasingly less significant so that by the time you are at 3-4k rpm these screws are pretty insignificant. What is significant at larger throttle openings would be the relative angles of the throttle plates.

The problem is that the FSM doesn't specify a procedure for properly aligning the throttle plates. They just say that the plates are set at the factory and to leave em the hell alone...

Being gearhead dweebs, we know that to achieve the smoothest possible running engine it is our goal for each of the 4 cylinders to contribute the identical amount of power per stroke. With Electronic Fuel Injection and Electronic Ignitions, the likelihood of balanced fueling a nd perfect ignition timing is much better than in the days of carburetors and points of the past. So our best tuning opportunity is to try to balance the air intakes, which can be best measured by the intake vacuums.

Being gearhead dweebs, we know that to achieve the smoothest possible running engine it is our goal for each of the 4 cylinders to contribute the identical amount of power per stroke. With Electronic Fuel Injection and Electronic Ignitions, the likelihood of balanced fueling a nd perfect ignition timing is much better than in the days of carburetors and points of the past. So our best tuning opportunity is to try to balance the air intakes, which can be best measured by the intake vacuums.

Prior "Unauthorised" TBS procedures suggested that you just open the throttle while observing the vacuum gauges and make the mechanical adjustments to the throttle linkage quickly. Surely that will work, but at what rpm do we need to go before the air from those bypass screws is nullified? And how sadistic is it to continually rev your engine while making these fine adjustments? (hint - they aren't all that quick)

Enter the RDC (Really Definitely Completely) Un-Authorized TBS.

The concept here is pretty simple. To align the throttle plates and eliminate the air contribution from the air by-pass screws, we just close them all the way before starting. Yep... it's just that simple.

So, to prove the concept I documented my most recent RDC UA TBS using a new (to me) Gunson Carb-tune vacuum gauge that I picked up over the winter:

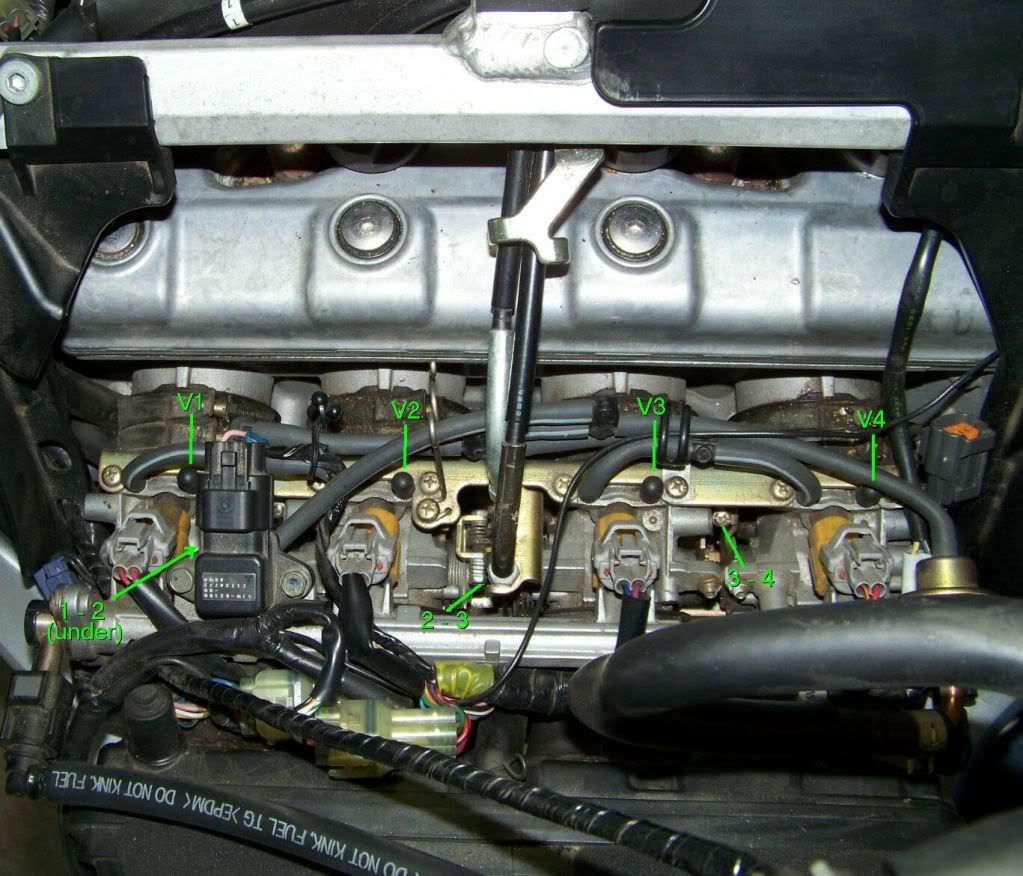

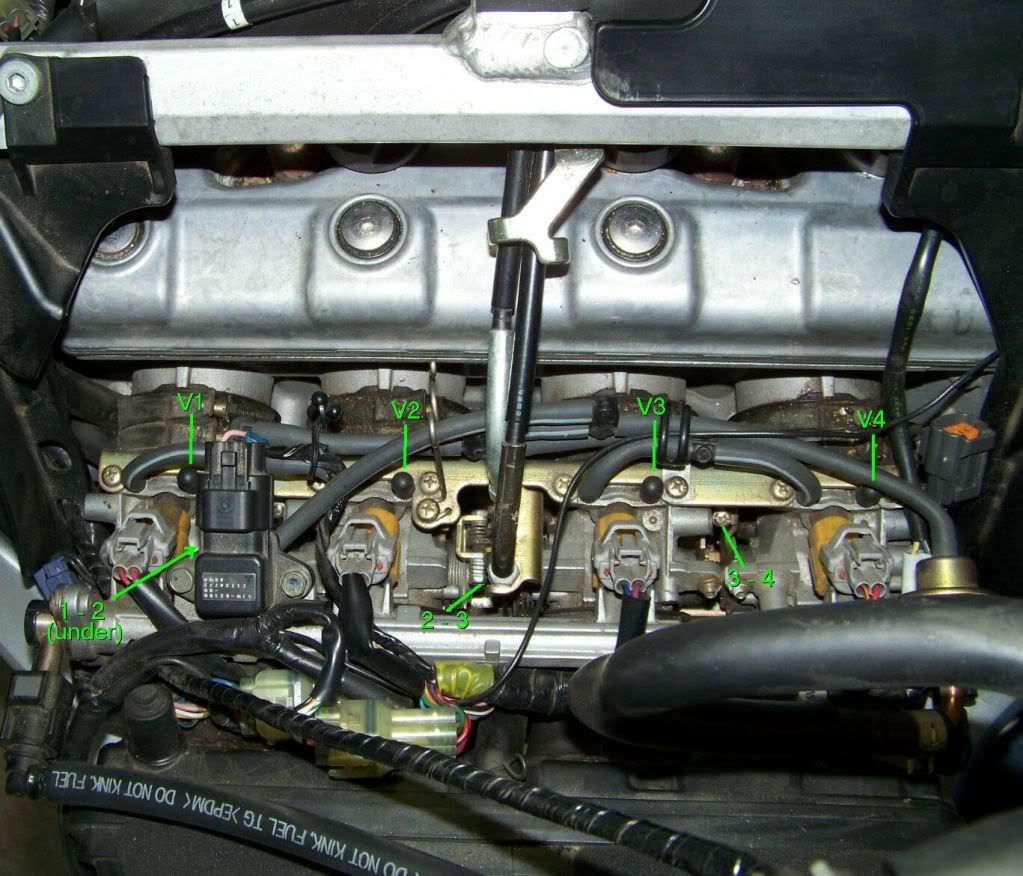

After propping the tank up out of the way, here are the important adjustment points

(note - your under tank could look this uncluttered after installing the WynPro PAIR Block-Off plates and removing all the PAIR crap):

V1 thru V4 are the 4 standard vacuum take-off points for hooking your vacuum gauge of choice to.

1-2, 2-3, and 3-4 are the mechanical linkage adjustment screws to adjust the relative angles of each cylinder's throttle butterfly plate.

Before I began, I documented what I had for vacuum at idle:

Not bad. Notice that #1 is a bit low and #4 is a bit high. Now, without making any adjustment I then revved the engine to ~3-4k rpm and used my Vista Cruise to hold it long enough to snap a picture:

Hello! What's that? Now cyl #1 is high and #4 is low!! This is not good. No, not good at all...

(well really these aren't all that bad, but you get the idea...)

Procedure:

Close down (lightly) all 4 of the Air Bypass screws:

Depending on how open they were before, your engine may not want to idle. You can either crank the idle adjustment (under the right side of the tank) or use your Vista Cruise to hold a reasonable idle, like I did.

Now that the air screws are out of the picture, you can adjust the throttle plate linkage screws (at idle, not while winding the piss out of your poor engine) and balance the vacuums with the throttle plates angles.

Important: Start by balancing cyl 2-3 since 1 and 4 are effected by that adjustment. The only tricky part is if 2-3 needs adjustment you can't get a screwdriver on the adjustment screw. So, take a guess, shut the engine off, and open the throttle enough to get at the screw head. Adjust it one way and then restart the bike to see if you guessed right.

Once 2-3 is good, the 1-2 and 3-4 adjustments can easily be made invivo. If you want to rev the engine to various RPMs to see how much things vary (or don't), knock yourself out (I did). In fact I was a bit nervous of running the engine in the garage for so long, even with water cooling.

When you are completely happy with the balance, I suggest shutting the engine down, and then dialing in ~ 1 turn CCW (open) into each air bypass screw. Restart the engine and adjust your idle to ~1100rpm.

Now recheck your vacuum gauge. Since the throttle plates are now aligned, if there is any mis-balance simply adjust the bypass screws until it is balanced at idle.

When I completed this procedure I had dead nutz balance at idle, and it varied very, very little at any throttle opening. I have not ridden the bike yet after adjusting. It may not amount to a hill of beans, but at least I now know that, unequivocally the throttle has been fully balanced and any vibration that remains is not being caused by an intake mis-balance.

(note that the RDCUA TBS cannot be performed on 3rd Gen FJRs)

3/2013 - I have captured and compiled a complete html version of this procedure and am hosting t at my fjr.nerds web space for posterity here: The Really, Definitely, Completely Un-Authorized Throttle Body Sync (TBS)

Re-edited 10/2012

This version of the UnAuthorized TBS procedure is based on a premise; that the ideal throttle synchronization is when the throttle plates are aligned with each other and parallel.

After a large number of uses, this procedure has been found to be very effective. Nobody who has used this procedure has ever said that it made their bike run worse. Most people say that their bike ran smoother (less vibration at ~4k-5k rpm ranges.

You will see some discussion in other posts about alternate ways to adjust the throttle plates. Some folks believe that you need to rev the engine. Some think that you need to load the engine and rev it. None of these other methods have been shown to be any more effective than doing it the way detailed here. And this way is a lot easier to do.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

The Really Definitely Completely UnAuthorized Throttle Body Sync

I decided to start a new thread to document this procedure. Not because it is so much different than any of the other UA TBS procedures, but because there are so many Throttle Body Sync threads. I'm hoping that this procedure becomes the new standard non-standard. The concept for this TBS procedure came from a thread / discussion I had with a short duration forum member from Maine, Alekso last year. The idea was to make a procedure that wasn't so convoluted and difficult to follow and understand as the original Unauthorized sync procedure.For those just tuning in, what's going on here is that the "official" throttle body sync procedure, the one called out in the Factory Service Manual (FSM) and specified as a "required" procedure at 4k mi. intervals (what?) is simply an adjustment of the air bypass screws at idle speed. These bypass screws have their primary effect on vacuum at idle speed, and have very little to do with how smoothly the engine runs at anything other than at idle or just above. As the throttle butterfly plates open, the tiny amount of air contributed to the total intake by the bypass circuit becomes increasingly less significant so that by the time you are at 3-4k rpm these screws are pretty insignificant. What is significant at larger throttle openings would be the relative angles of the throttle plates.

The problem is that the FSM doesn't specify a procedure for properly aligning the throttle plates. They just say that the plates are set at the factory and to leave em the hell alone...

Prior "Unauthorised" TBS procedures suggested that you just open the throttle while observing the vacuum gauges and make the mechanical adjustments to the throttle linkage quickly. Surely that will work, but at what rpm do we need to go before the air from those bypass screws is nullified? And how sadistic is it to continually rev your engine while making these fine adjustments? (hint - they aren't all that quick)

Enter the RDC (Really Definitely Completely) Un-Authorized TBS.

The concept here is pretty simple. To align the throttle plates and eliminate the air contribution from the air by-pass screws, we just close them all the way before starting. Yep... it's just that simple.

So, to prove the concept I documented my most recent RDC UA TBS using a new (to me) Gunson Carb-tune vacuum gauge that I picked up over the winter:

After propping the tank up out of the way, here are the important adjustment points

(note - your under tank could look this uncluttered after installing the WynPro PAIR Block-Off plates and removing all the PAIR crap):

V1 thru V4 are the 4 standard vacuum take-off points for hooking your vacuum gauge of choice to.

1-2, 2-3, and 3-4 are the mechanical linkage adjustment screws to adjust the relative angles of each cylinder's throttle butterfly plate.

Before I began, I documented what I had for vacuum at idle:

Not bad. Notice that #1 is a bit low and #4 is a bit high. Now, without making any adjustment I then revved the engine to ~3-4k rpm and used my Vista Cruise to hold it long enough to snap a picture:

Hello! What's that? Now cyl #1 is high and #4 is low!! This is not good. No, not good at all...

(well really these aren't all that bad, but you get the idea...)

Procedure:

Close down (lightly) all 4 of the Air Bypass screws:

Depending on how open they were before, your engine may not want to idle. You can either crank the idle adjustment (under the right side of the tank) or use your Vista Cruise to hold a reasonable idle, like I did.

Now that the air screws are out of the picture, you can adjust the throttle plate linkage screws (at idle, not while winding the piss out of your poor engine) and balance the vacuums with the throttle plates angles.

Important: Start by balancing cyl 2-3 since 1 and 4 are effected by that adjustment. The only tricky part is if 2-3 needs adjustment you can't get a screwdriver on the adjustment screw. So, take a guess, shut the engine off, and open the throttle enough to get at the screw head. Adjust it one way and then restart the bike to see if you guessed right.

Once 2-3 is good, the 1-2 and 3-4 adjustments can easily be made invivo. If you want to rev the engine to various RPMs to see how much things vary (or don't), knock yourself out (I did). In fact I was a bit nervous of running the engine in the garage for so long, even with water cooling.

When you are completely happy with the balance, I suggest shutting the engine down, and then dialing in ~ 1 turn CCW (open) into each air bypass screw. Restart the engine and adjust your idle to ~1100rpm.

Now recheck your vacuum gauge. Since the throttle plates are now aligned, if there is any mis-balance simply adjust the bypass screws until it is balanced at idle.

When I completed this procedure I had dead nutz balance at idle, and it varied very, very little at any throttle opening. I have not ridden the bike yet after adjusting. It may not amount to a hill of beans, but at least I now know that, unequivocally the throttle has been fully balanced and any vibration that remains is not being caused by an intake mis-balance.

Last edited by a moderator: