FatNakedGuy

Well-known member

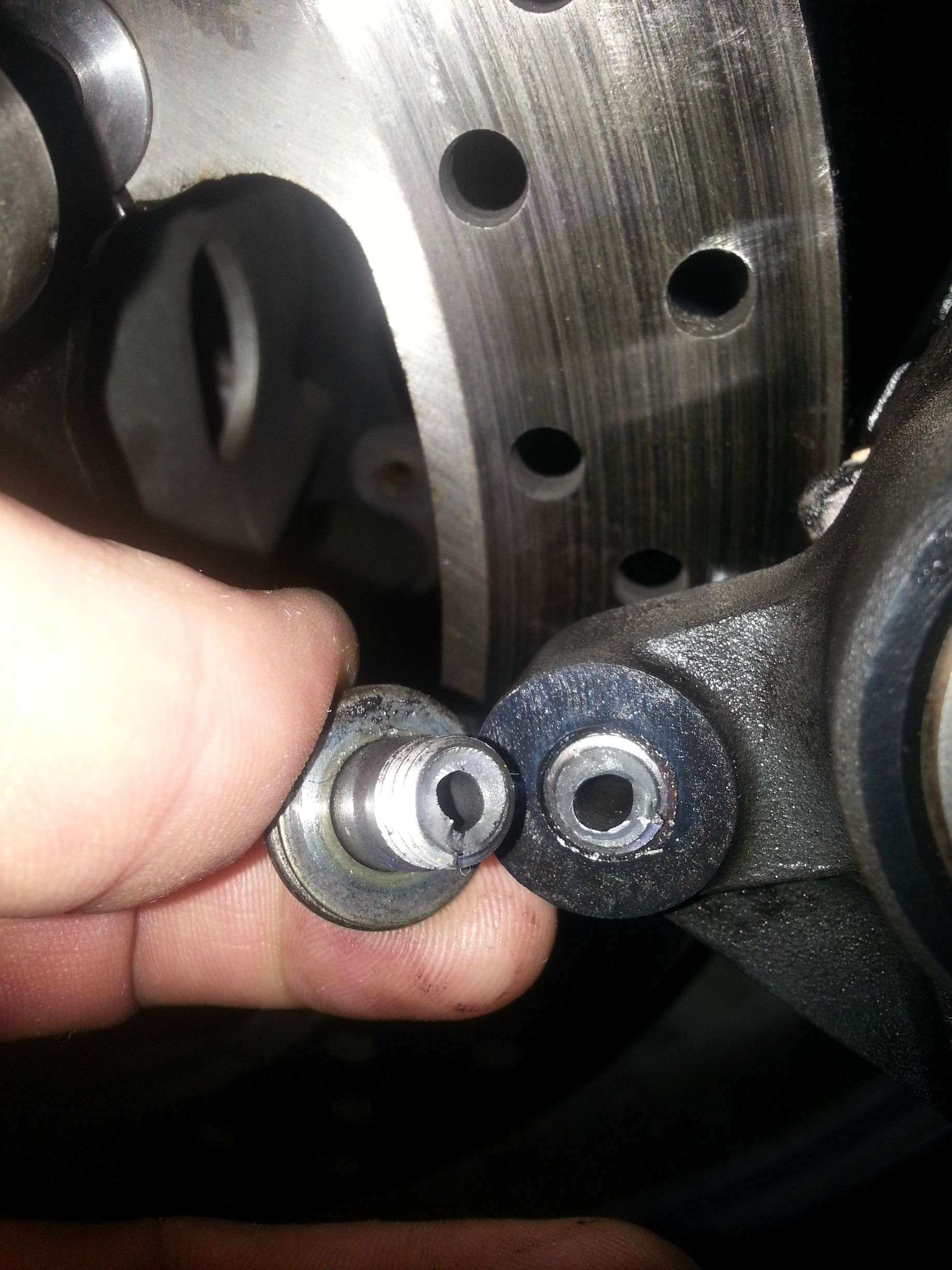

well damn.. caliper bolt just snapped while using a torque wrench at 29lbs. The other three went in fine. Snapped in two where the two caliper pieces joint, and was able to remove the caliper

I searched the threads here and found people saying to use an easy out? what is that, and what brand/where to buy?

thanks!

p.s.

why are the brake bolts hollow?

<a href="https://imgur.com/2iVFyts"><img src="https://i.imgur.com/2iVFyts.jpg" title="Hosted by imgur.com" /></a>

I searched the threads here and found people saying to use an easy out? what is that, and what brand/where to buy?

thanks!

p.s.

why are the brake bolts hollow?

<a href="https://imgur.com/2iVFyts"><img src="https://i.imgur.com/2iVFyts.jpg" title="Hosted by imgur.com" /></a>