Spud

Well-known member

I'm going to replace the Shock on my '08. I found a low-miles Gen 3 shock thanks to the forum, and it's on the way.

In looking over the procedure, I've found some helpful links (ie https://www.fjrforum.com/forum/index.php?showtopic=102533)

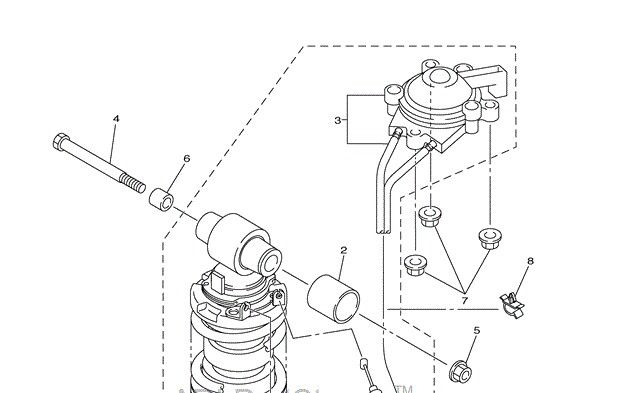

In that nice write-up, it says "there is a bushing on the right side of the bike that the head of the bolt will go against. This bushing will probably fall out but is easy to replace before mounting the new shock."

My question: Is the bushing something to be replaced? Bike has 56K miles. I've been thinking I just needed to swap shocks and didn't need any parts....

Thanks in advance.

In looking over the procedure, I've found some helpful links (ie https://www.fjrforum.com/forum/index.php?showtopic=102533)

In that nice write-up, it says "there is a bushing on the right side of the bike that the head of the bolt will go against. This bushing will probably fall out but is easy to replace before mounting the new shock."

My question: Is the bushing something to be replaced? Bike has 56K miles. I've been thinking I just needed to swap shocks and didn't need any parts....

Thanks in advance.