UselessPickles

Making Grand Canyon replicas from air boxes...

If you don't know what the "Wicked Webby" air box mod is, read this: https://www.fjrforum.com/forum/index.php?showtopic=114873

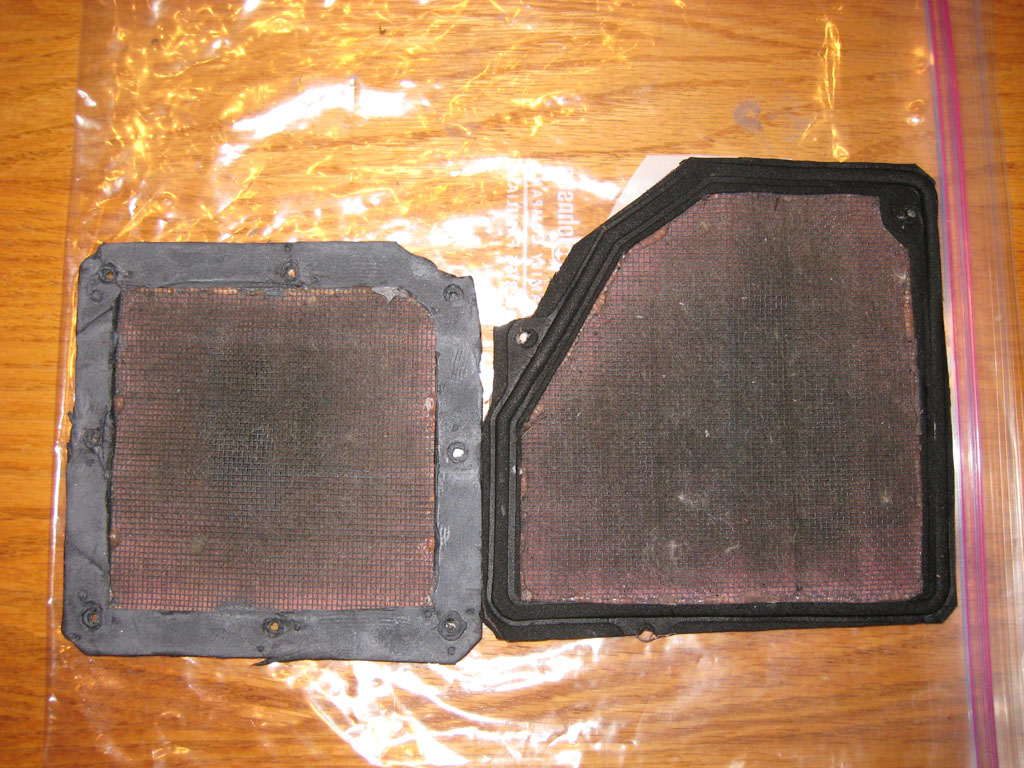

So here's my custom air filters after about 4,000 miles:

That's the outside facing sides of the filters. Pretty dirty, but it was to be expected that I'd have to clean them fairly often (I was going with every oil change). Now let's check out the inside facing sides...

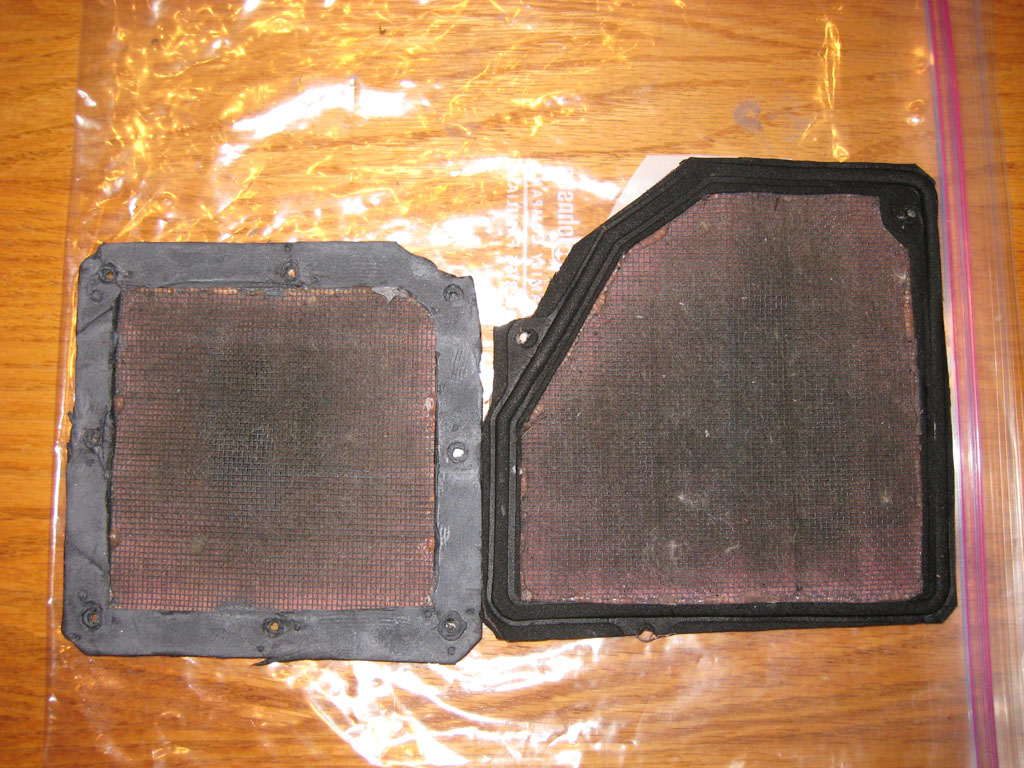

OH CRAP! That doesn't look good. In case you miss it, there's a chunk of the aluminum wire mesh missing from one of the filters. My guess is that the creases in the wire mesh were weakened when I flattened the pleats, and the engine sucked it off.

I took my air box off and searched everywhere in the air box, the intake tubes and throttle bodies hoping to find it lodged somewhere. It was nowhere to be found. One of my butterfly valves has a light scrape on it, and one of the intake valves for the same cylinder had some black gunk on it (looked at it through the fuel injection port while shining a flashlight in through the throttle body). The rest of my intake valves were spotless (sorry; no pics). My guess is that the wire mesh got trapped by the valve until it melted.

So how bad could this be? My engine has been running just as good as always with no unusual sounds, vibrations or loss of power. I assume that any damage has already been done by now. I'll be ordering a new air box and only modify it partially so that a stock-style air filter can still be used to prevent my engine from eating any more air filters.

Any suggestions on how to assess the possible damage? How likely is it that I got away with insignificant damage?

So here's my custom air filters after about 4,000 miles:

That's the outside facing sides of the filters. Pretty dirty, but it was to be expected that I'd have to clean them fairly often (I was going with every oil change). Now let's check out the inside facing sides...

OH CRAP! That doesn't look good. In case you miss it, there's a chunk of the aluminum wire mesh missing from one of the filters. My guess is that the creases in the wire mesh were weakened when I flattened the pleats, and the engine sucked it off.

I took my air box off and searched everywhere in the air box, the intake tubes and throttle bodies hoping to find it lodged somewhere. It was nowhere to be found. One of my butterfly valves has a light scrape on it, and one of the intake valves for the same cylinder had some black gunk on it (looked at it through the fuel injection port while shining a flashlight in through the throttle body). The rest of my intake valves were spotless (sorry; no pics). My guess is that the wire mesh got trapped by the valve until it melted.

So how bad could this be? My engine has been running just as good as always with no unusual sounds, vibrations or loss of power. I assume that any damage has already been done by now. I'll be ordering a new air box and only modify it partially so that a stock-style air filter can still be used to prevent my engine from eating any more air filters.

Any suggestions on how to assess the possible damage? How likely is it that I got away with insignificant damage?