Slonishku

Well-known member

I started fitting my TAT to my FJR last week. The plan was to get it done in time to give it a local road test of a few miles, then a dozen or so miles, then ride the whole thing Bakersfield-Oakland-Concord-Bakersfield over the weekend, as I had Naval Reserve duty this weekend. I ran out of time looking for parts last week, so the Oakland ride didn't pan out.

I got home sunday and finished assembly of the main tank bulkhead fitting, got everything set-up, and took the TAT on its maiden vooyage this morning (to work). I'm at work now, and everything seemed to go well this morning.

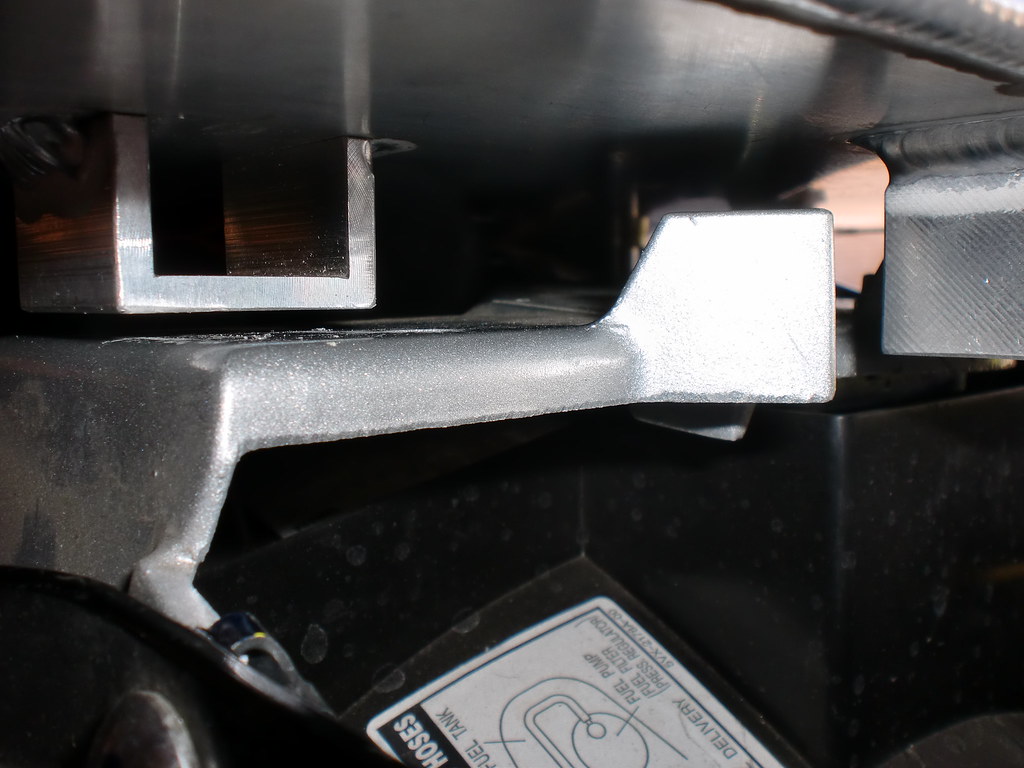

Here are some pictures from the process. I won't go into excruciating detail- just some of the more salient points.

I got home sunday and finished assembly of the main tank bulkhead fitting, got everything set-up, and took the TAT on its maiden vooyage this morning (to work). I'm at work now, and everything seemed to go well this morning.

Here are some pictures from the process. I won't go into excruciating detail- just some of the more salient points.