I just torqued my head bearings with the spanner (bought from Bike Johnny - it came airmail right away).

On my relatively new 06, it took about 1/3 -1/2 of a revolution for the bottom nut to torque down. So the nut was loose. I think a clunking sound in the front end is related to this being loose.

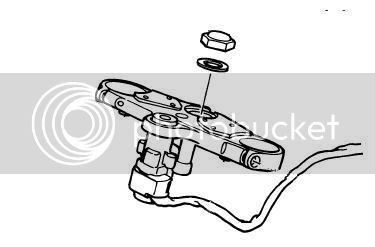

I torqued the bottom nut to 37 ft lbs. Click - no problem. But then I went to torque the top nut to 13 ft lbs and no click and the plastic washer just kept squeezing out. The plastic washer simply doesn't allow the nut to torque up to 13 ft lbs. So I had a choice, do I eliminate the plastic washer between the two nuts, or just cinch it down before the washer starts to deform. I elected to keep the plastic washer and cinch down by hand rather than torque with no washer.

I figure the lock washer that goes over top, and the 85 ft lbs from the nut above the steering stem will keep things in check and the plastic washer, might eliminate vibration, up through the triple clamp and bars.

Has anybody had this happen?