1. Crackle and pop off-throttle when cold is an emissions system. Air is injected into the exhaust stream right where the headers meet the cylinder head, allowing unburned fuel to burn in the exhaust pipe rather than make its way out to our breathing air as actual gasoline droplets. You hear it as little tiny backfires.

2. FJRs are well-known for clunk going into first.

3. No reason to hold the clutch if you're in neutral. What's happening is the input shaft of the transmission coasts down to no rotation, and when you try to get first, the dogs can't engage. You can't shift a moto trans without moving parts in the gearbox.

4. 10 mph is WAY to slow for clutch all the way out! The bucking is driveline lash, and a little bit of that cush-drive mechanism on the middle shaft.

Stop babying the bike. 1200 RPM is no place to be running it! We'll take it away from you if that continues, ya hear??!?????!

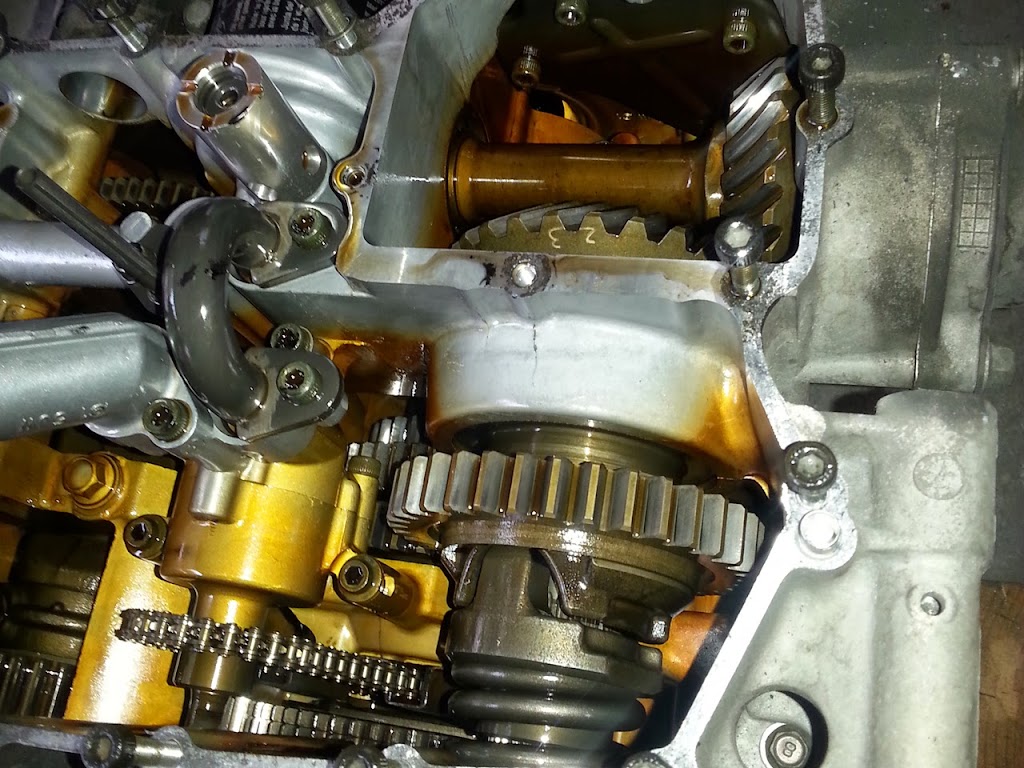

If you don't know what a cush drive is, don't worry about it. There was a time when I didn't know, either. Usually it's a set of rubber bumpers in the rear wheel, between the sprocket and the wheel. The sprocket applies drive force to the wheel through that rubber bumper, and when you let off the throttle, the wheel applies drive force to the sprocket, chain, and motor through the other side of the rubber bumper. It's softens the blows of the driveline slack being taken up hard. In the FJR, there's a weird-looking spring-loaded cam thingie on the shaft between the transmission and the bevel gear that drives the shaft to the wheel. That spring-loaded cam thingie serves that function for our bike, and with a hard driveline hit, that cam will rotate on that shaft, compressing the spring, and soaking up some of that whack that would otherwise go right out to the wheel, or back into the transmission, depending on which side of the driveline is being loaded.

I'd seen that mechanism as drawings in the shop manual but never understood its purpose until I actually met mine face to face and held it in my hands: in the picture that big gear in the middle is driven by the transmission but is not splined to that shaft. It drives the shaft through that u-shaped notch on the big pin, with the pin being pressed in by the spring. That piece with the big pin

is splined to the shaft. A hard driveline hit, like dumping the clutch, will be softened just a bit by that gear turning a few degrees around the shaft and being re-centered by spring pressure. your 10-mph bucking probably gives that a workout, too.

OK, I got carried away with number 4. Sue me....