ionbeam

2 FUN

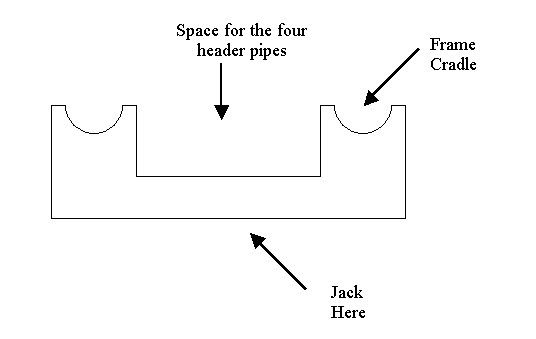

I just did a search but can't find a gem of an idea from FJRPierre, perhaps his article and pixs were lost in the First Great Hack Attack. Basically FJRPierre used a piece of lumber to create a bridge that runs perpendicular to the headers with blocks on each end that rest on the frame, you jack up using the bridging lumber. Picture a U with the bottom of the U the same width as the frame. Err, :blink: like I said, ping FJRPierre for the straight stuff and pixs.

Admin(s)? Can you find this posting?

Edited to add this poor man's sketch:

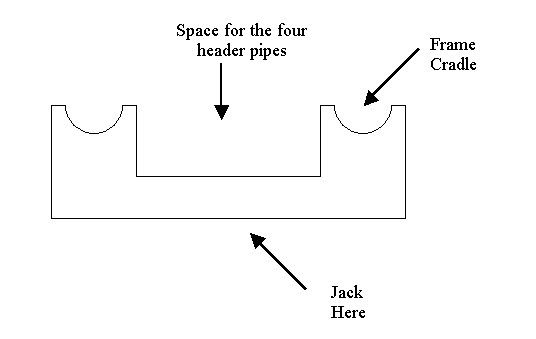

Admin(s)? Can you find this posting?

Edited to add this poor man's sketch:

Last edited by a moderator: