Joe2Lmaker

Well-known member

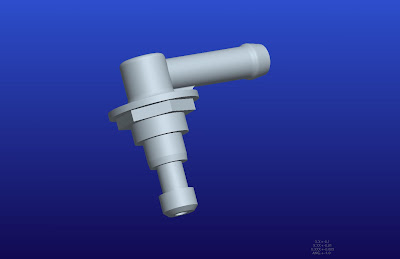

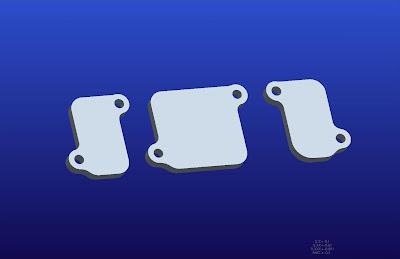

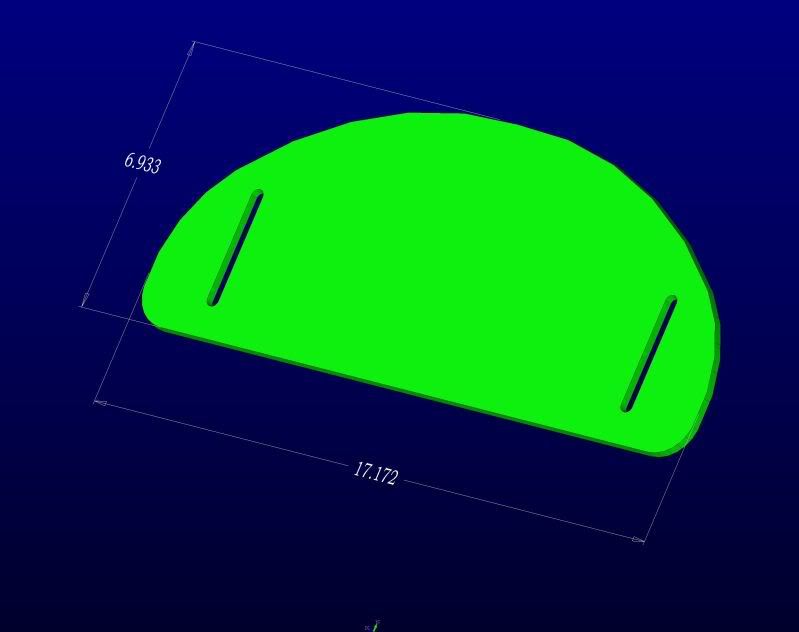

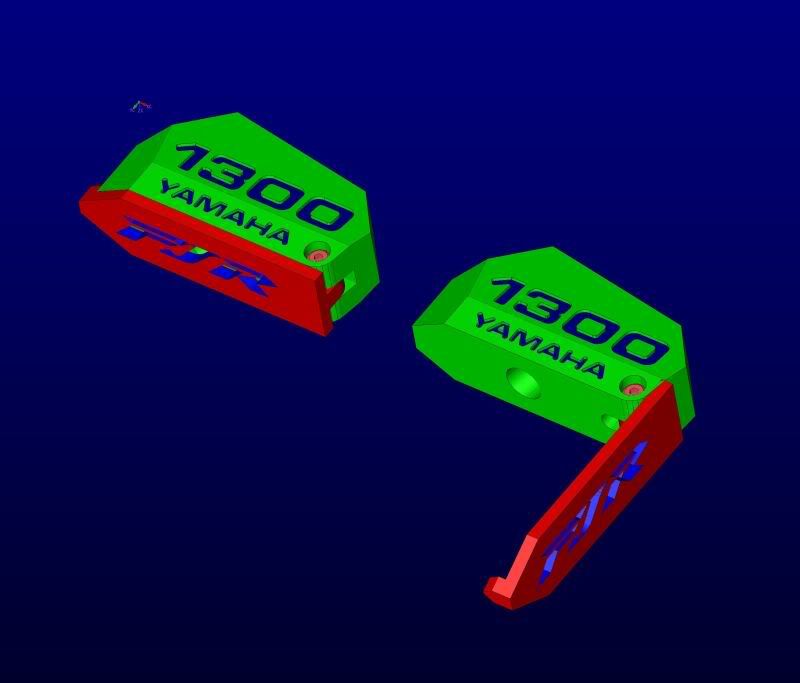

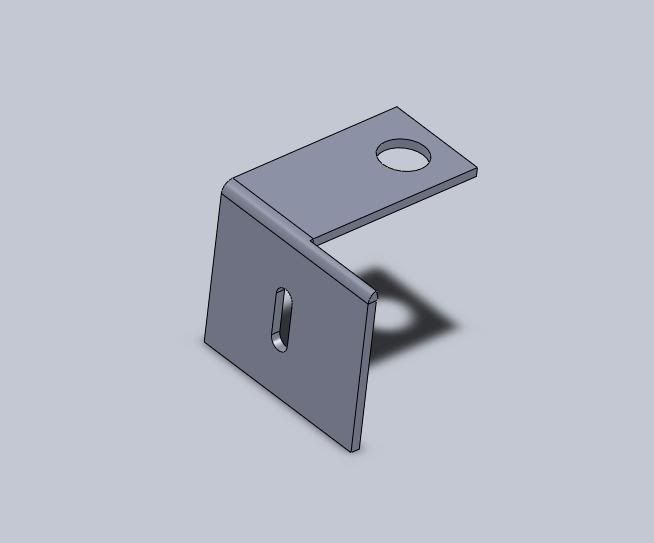

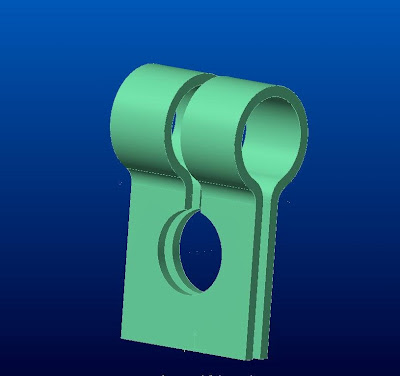

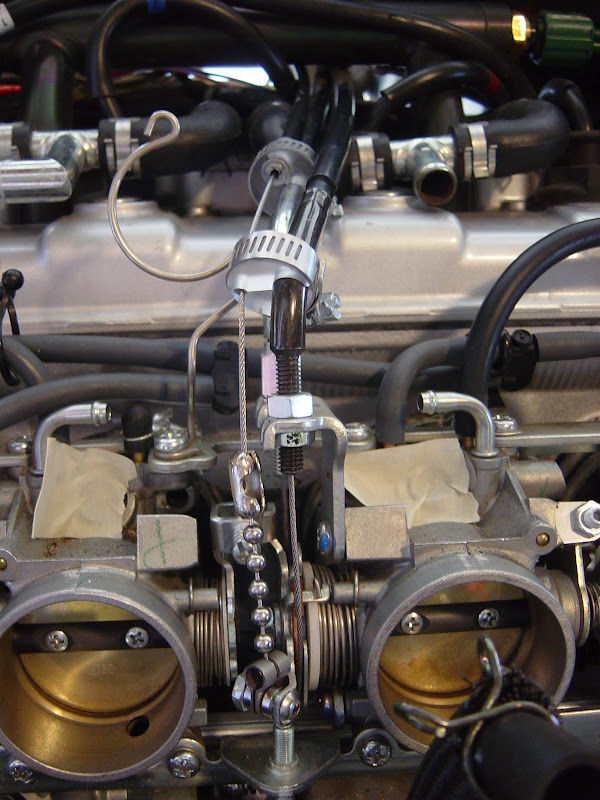

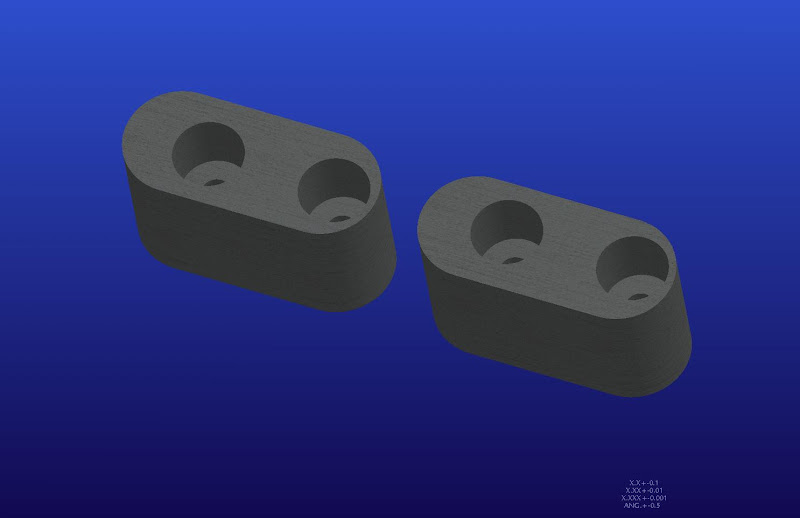

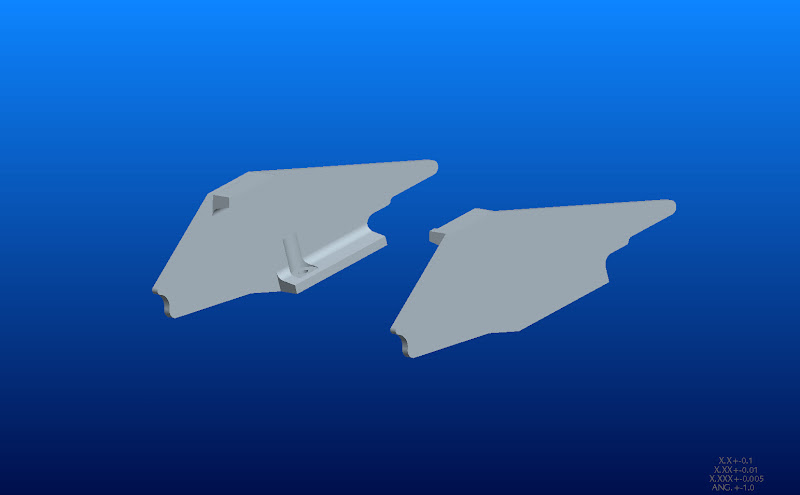

This thread is for people who use CAD tools.

People who create FJR or motorcycle related CAD models can post screen shots of their work. Anyone with the machine tools and CAD/CAM tools to reproduce that work can PM the originator and request the model in a format that will work for them. It is up to the originator to grant your request. You may want to keep in mind that this is an exchange and offer to trade.

Rules:

1.) Rules are subject to change.

2.) Time is money. Respect the time others have invested in producing their CAD models.

3.) Do not use the models to produce any parts for profit without the originator's consent.

4.) Do not share copies of the models without the originator's consent.

5.) Don't get yourself on a **** list. If you burn one of the contributors to this thread, the other's will probably find out.

People who create FJR or motorcycle related CAD models can post screen shots of their work. Anyone with the machine tools and CAD/CAM tools to reproduce that work can PM the originator and request the model in a format that will work for them. It is up to the originator to grant your request. You may want to keep in mind that this is an exchange and offer to trade.

Rules:

1.) Rules are subject to change.

2.) Time is money. Respect the time others have invested in producing their CAD models.

3.) Do not use the models to produce any parts for profit without the originator's consent.

4.) Do not share copies of the models without the originator's consent.

5.) Don't get yourself on a **** list. If you burn one of the contributors to this thread, the other's will probably find out.

Last edited by a moderator: