SockMonkey

Makin' Some Noise

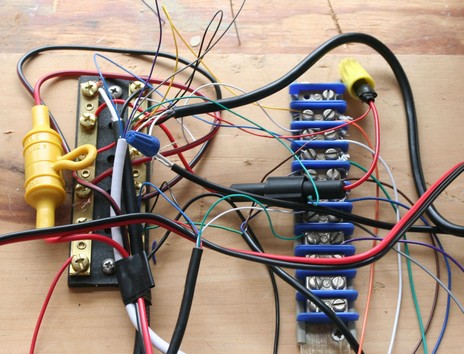

Pics of a drop-in electrical panel for various accessories that I built Saturday afternoon:

This panel supplies power and switching for the following:

1) PIAA 1100X Driving Lights (isolated circuit; AutoSwitch controls);

2) Power: Sat. Radio power supply (switched circuit thru FuzeBlock);

3) Power: AutoSwitch (switched circuit thru FuzeBlock);

Note: Primary from battery and Powerlet outlet connect directly to barrier strip

I opted to use the tray below the seat for this panel for accessability and serviceability reasons. There are still plenty of spaces elsewhere on the bike for other boxes should I choose to add additional accessories in the future. I'll finish routing the remaining cabling thru the bike today and post up pics of the completed project later.

This panel supplies power and switching for the following:

1) PIAA 1100X Driving Lights (isolated circuit; AutoSwitch controls);

2) Power: Sat. Radio power supply (switched circuit thru FuzeBlock);

3) Power: AutoSwitch (switched circuit thru FuzeBlock);

Note: Primary from battery and Powerlet outlet connect directly to barrier strip

I opted to use the tray below the seat for this panel for accessability and serviceability reasons. There are still plenty of spaces elsewhere on the bike for other boxes should I choose to add additional accessories in the future. I'll finish routing the remaining cabling thru the bike today and post up pics of the completed project later.