Yes. The OE spanner must be used at a 90 degree angle so it doesn't add to the length (and therefore alter the torque results) of the wrench.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Homemade Steering Bearing Socket

- Thread starter PhilJet09

- Start date

Help Support Yamaha FJR Motorcycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

kurbennett64

Active member

Thanks Fred.

PhilJet09

Nondescript FJR Hierarchy Displayed

Queensland Ken

Well-known member

I had a C spanner that I cut, welded a socket & made two tools from one.

Works a treat.

Works a treat.

bigjohnsd

2021 BMW R1250GSA

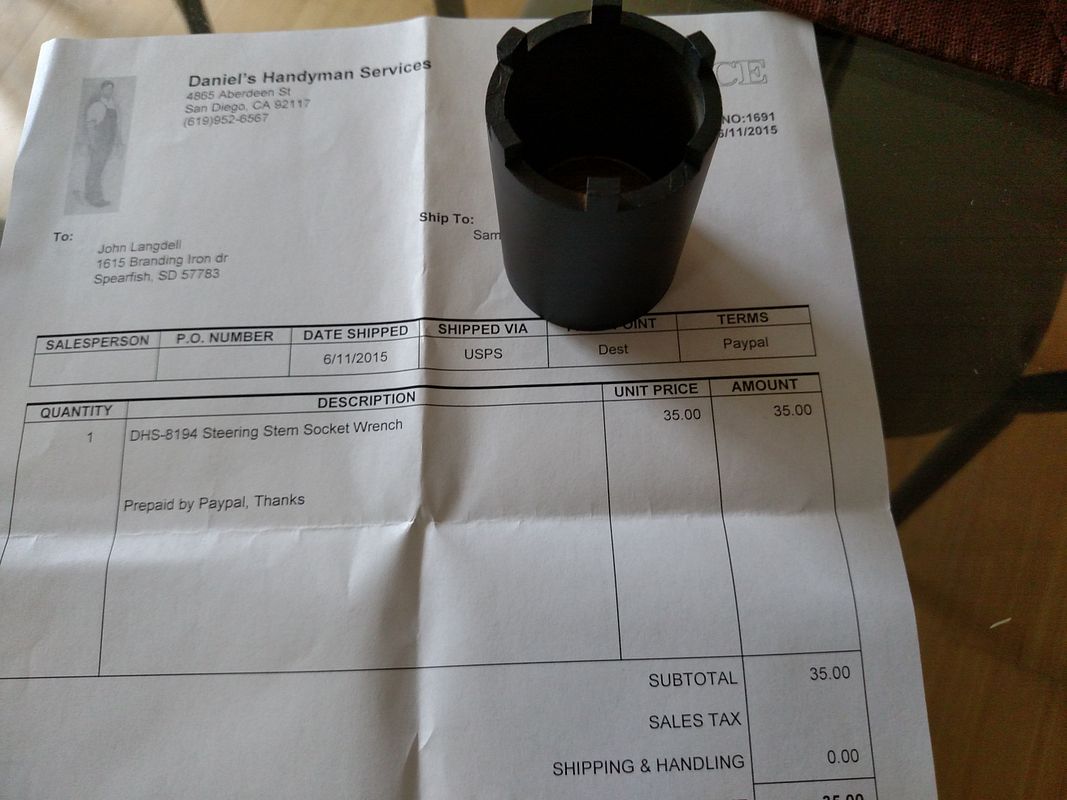

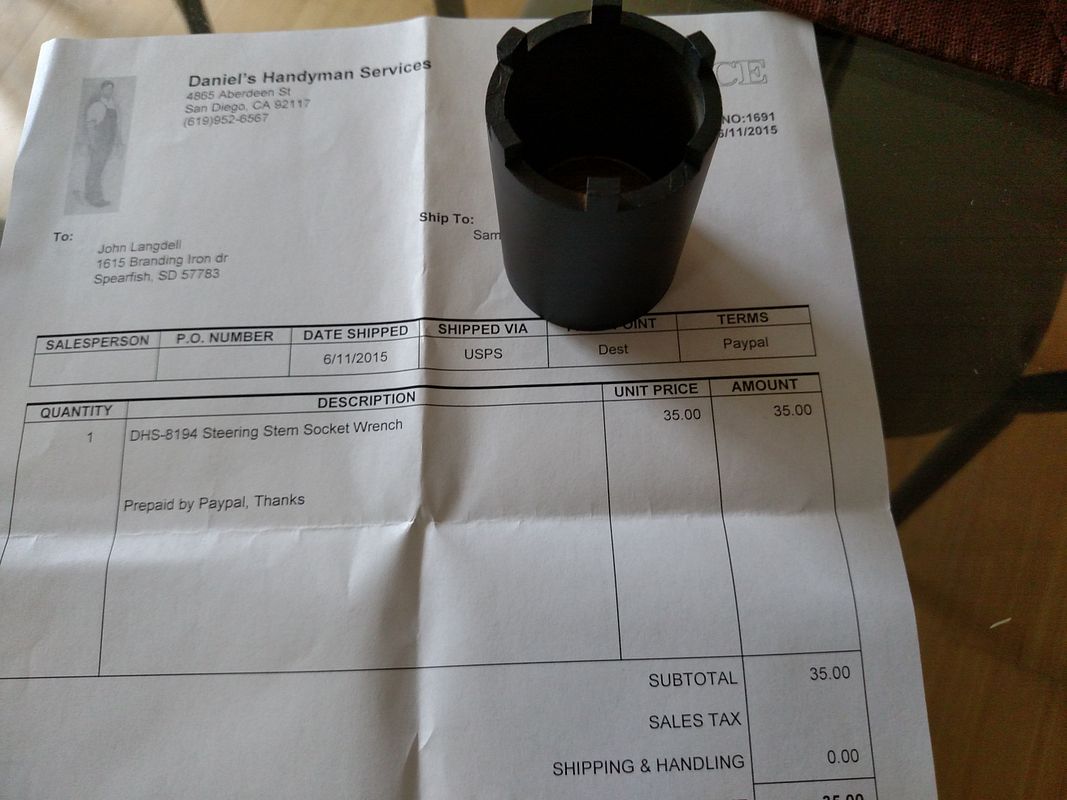

1/2" Drive Special socket,

1/2" drive 36mm socket purchased at Sears for $8.00

Last edited by a moderator:

08FJR4ME

-WYNPRO-

John, are you saying this is just a modified sears 36mm socket? I will have to check this out since I seem to be feeling something slightly clunking in the handle bars. It seems to be more noticeable as of lately. With almost 75K it may be time to check the bearing adjustment and do some lubrication.

1/2" Drive Special socket,

1/2" drive 36mm socket purchased at Sears for $8.00

https://www.sears.com/craftsman-36mm-easy-to-read-socket-12-pt/p-00950752000P?prdNo=1&blockNo=1&blockType=G1

Dave

Last edited by a moderator:

$159.99

FLAVOR Men Brown Leather Motorcycle Jacket with Removable Hood (Large (US standard), Brown)

FLAVOR Leather

$91.99

Edwards Maintenance Kit fits 2003-2020 Yamaha FJR1300 Sport Touring

Edwards Motorsports & RV's

$79.95

Harley-Davidson Water-Resistant Travel Hybrid Duffel Bag/Backpack - Black

Wisconsin Harley-Davidson

$19.99

MOREOK Winter Gloves -10°F 3M Thinsulate Warm Gloves Bike Gloves Cycling Gloves for Driving/Cycling/Running/Hiking-Black-L

MOREOK-US (Ships from USA)

$64.99

Edwards Oil Change Kit fits 2003-2020 Yamaha FJR1300 Sport Touring

Edwards Motorsports & RV's

$89.45

No Cutting Motorcycle Frame Slider Anti-collision Drop For Yamaha FJR1300 FJR 1300 2006-2011 motorcycle crash pad(Carbon Fiber Look)

dengzhoushijiushuncaishangmaoyouxiangongsi

$197.39

$209.99

Milwaukee Leather SH1408 Men's Sporty Crossover Vented Black Motorcycle Leather Scooter Jacket - Large

Amazon.com

$24.37

Fuel Tank Sticker Motorcycle Stickers for Yam&aha FJR1300 FJR 1300 Tank Pad Protector Decal Emblem Side Fairing Symbol Adventure

nanyangshixianpushangmaohanggerenduzi

$98.16

25-1775 Replacement for All Balls Wheel Bearing Kit (25-1775) for Yamaha FJR1300 03-16 FJR1300ES 14-18

Otisdelilah Auction

bigjohnsd

2021 BMW R1250GSA

No Dave, the tool appears to have been machined from bar stock, the 36mm socket is what I believed/believe I need to remove the nut off the top of the steering stem, which is covered up by my MV Motorad Riser setup.

08FJR4ME

-WYNPRO-

O.K. I still plan on making my own. Just looking for a short cut and I still might look for the right size socket to cut up to make this happen. I believe you are correct that It is a 36mm nut.

Thanks,

Dave

Thanks,

Dave

bigjohnsd

2021 BMW R1250GSA

I was going to go the DIY route then after I figured out the socket to modify was going to cost $8-10 and that it was likely that I'd have 3-5 hours into grinding the socket and no guarantee of success, I cheaped out and bought the $35 special.O.K. I still plan on making my own. Just looking for a short cut and I still might look for the right size socket to cut up to make this happen. I believe you are correct that It is a 36mm nut.

Thanks,

Dave

Dave,O.K. I still plan on making my own. Just looking for a short cut and I still might look for the right size socket to cut up to make this happen. I believe you are correct that It is a 36mm nut.

Per the 1st post of this thread, a 1 1/4" 12 point was a good starting socket for grinding down.

Also, if you wanted to make the job quicker and easier you could leave just two of the six nubs on the socket. That would be plenty strong enough for the torque values involved in this job, no doubt. The Yamaha spanner tool manages it on just one tab.

Or if you want really easy you could just borrow my JustRoy socket.

08FJR4ME

-WYNPRO-

Fred,

Thanks for the offer and info. You have to remember I like to tinker too.

Dave

Thanks for the offer and info. You have to remember I like to tinker too.

Dave

Just use some slip-joint pliers and tighten the ring nuts by calibrated feel.

I can't believe the shop techs use a torque wrench for this application.

I can't believe the shop techs use a torque wrench for this application.

TomInPA

Well-known member

When working on your own bike, it's your choice. A commercial shop doing this would be using a torque wrench for liability avoidance. Considering the critical nature of the steering components, I would want to document it was done right in case the customer had an issue and wanted to get rich on my alleged negligence.Just use some slip-joint pliers and tighten the ring nuts by calibrated feel.

I can't believe the shop techs use a torque wrench for this application.

I just did the maintenance using a spanner wrench, and the torque values worked pretty good. I have done it by "feel" on other bikes in the past. Before starting I was surprised to find my steering head nut that is supposed to be at 85 ft-lbs was not even finger tight.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 11

- Views

- 842