I'm doing a major lube service (among a lot of other things) on an 05 ABS with 73k.

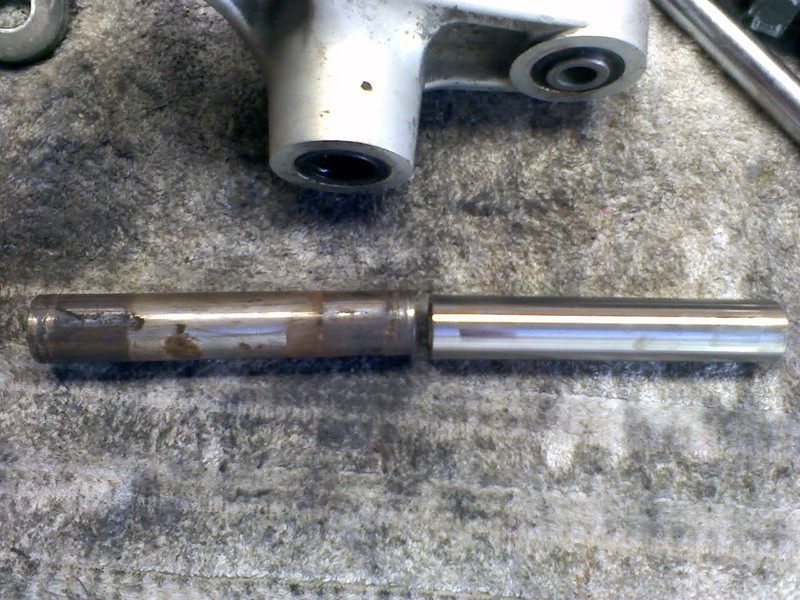

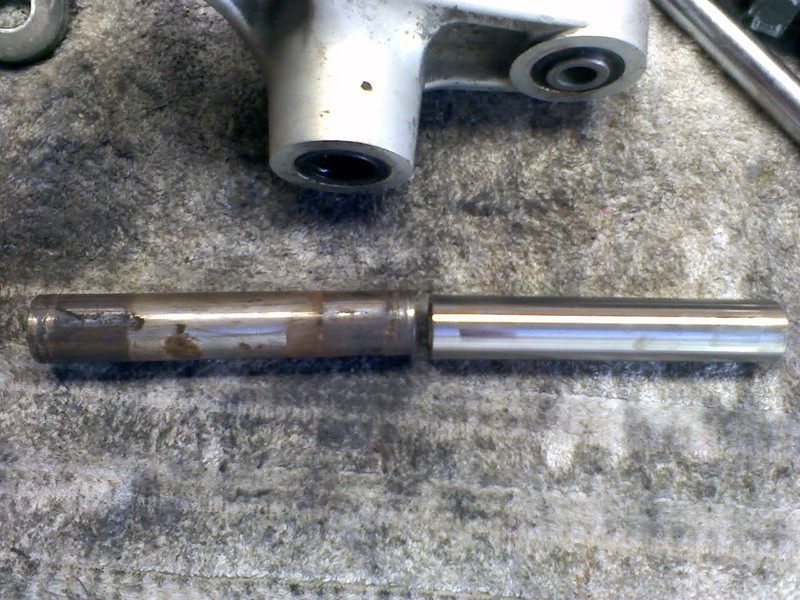

This is what the center relay arm "collar" (as Mamayama calls it, I call it a bushing) looks like when it's installed dry from the factory.

The bearings still turned - they squeeked, but amazingly, still turned! Had this not been caught and the corrosion continued, the bearings would have frozen, the bushing would no longer do the job, and the dog bones would have failed. Result? Collapse of the rear suspension. Could have been an exciting time.

On the right is a maintained bushing from an 03 relay arm with over 90k, on the left, the other.

Let this serve as a warning to the collective - the relay arm is a ***** to get to and do right, but ya'all need to do it. Do it at least once to ensure that it's actually lubed. Do it yourself, pay someone, whatever - but do it.

I've now done 4 major lube jobs and this one is the only one I found dry. And I mean dry, as in dusty. No evidence of any grease ever being used from install on. It's worrisome, to say the least.

This is what the center relay arm "collar" (as Mamayama calls it, I call it a bushing) looks like when it's installed dry from the factory.

The bearings still turned - they squeeked, but amazingly, still turned! Had this not been caught and the corrosion continued, the bearings would have frozen, the bushing would no longer do the job, and the dog bones would have failed. Result? Collapse of the rear suspension. Could have been an exciting time.

On the right is a maintained bushing from an 03 relay arm with over 90k, on the left, the other.

Let this serve as a warning to the collective - the relay arm is a ***** to get to and do right, but ya'all need to do it. Do it at least once to ensure that it's actually lubed. Do it yourself, pay someone, whatever - but do it.

I've now done 4 major lube jobs and this one is the only one I found dry. And I mean dry, as in dusty. No evidence of any grease ever being used from install on. It's worrisome, to say the least.