Ok Ok Ok So it's a complete waste of time. the manufacturing process has advanced to the stage we are now forced to accept nothing can be done to remotely give us an edge.

Guess me putting mothballs in the tank isn't worth killing the little fukers for the miniscule increase in performance then.. The tree huggers are now going to be knocking down me door!

Agreed. There is always ways to smooth out flow and increase fuel air mix.

Keep in mind, some of our bikes were cast over 15 years ago.

Well, allrighty then, the falsus nomen Flying Pig Project

How to make 650 lbs fly quicker, faster and higher.

All hot rodding items on the table. First, let's design the project (OMG, an engineering plan on which to stage a project). First, what target power level are you aiming for? What kind of Sport/Tour driving experience will the upgraded engine provide? Will the torque and HP come from more top end RPM or lower RPM breathing? What goals are there for fundamentals like piston size, rod stroke, combustion chamber volume & shape, valve size, compression ratio and cam profile? On the secondary items, how will the fuel mapping take place and how will you get an aftermarket ignition controller installed? Once all this is settled, it's time to look at air intake, intake runner length, header shape, length and exhaust system. While thinking things over, it's also time to dig out the plastigauge, micrometer and scales for a little blueprinting and balancing.

On the other hand, I'm pretty sure that an inexperienced person could do a fair amount of harm if they try to do shaping beyond just polishing. I have had the cylinder head off my '04 FJR, I've looked at the intake runners and cylinder head pockets (hardly a pocket) and decided that the 2 - 5 hp wouldn't be worth the work.

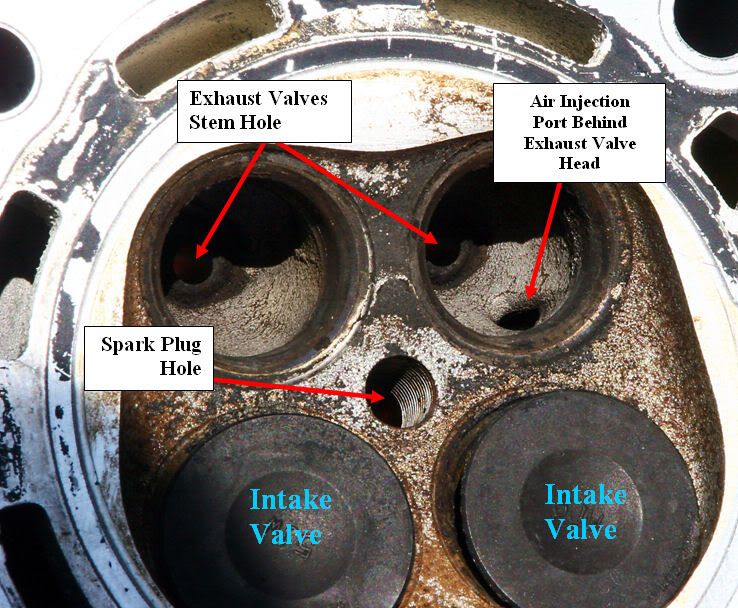

Look at all that opportunity to polish! Man, just makes ya want to break out the pneumatic hone... It sure makes a feller want to smooth, blend and knife edge ****.

Thank you for the pictures. There is clearly plenty of room for a larger intake valve, and possibly even a larger exhaust valve.

I have had plenty of flying pig projects, this should be nothing new. I've nitrous'ed Acura Legends, supercharged several trucks,

I was trying to illustrate a point with the Flying Pig, to go quick and fast the bike needs to be light. If the bike can't be light then when hot rodding the engine the power output profile will have to be favorable for moving mass, which probably won't make for a good sport/tour power profile. In my first post I was indicating that a good engine build program needs goals and engine power improvement is a system, you can't modify one element in the middle and expect the whole system to get a lot better.

Power adders are great but again, they aren't really easy to install and get dialed in for acceptable daily use. Things like NOS is really for track only WOT operation. Positive pressure solutions really need a thicker head gasket to reduce compression. Turbos come with a snakes nest of tubing. Supercharging has a lot of parasitic drag and is noisy. Electric superchargers will cook the FJRs electrical system. But most of all, the FJR's spark timing is not accessible and you would have to install an aftermarket ignition system to take advantage of most of the power adders.

The sport touring profile isnt ideal, but as you stated, the engine is a system, and there are clearly some weak points restricting it.

Power adders are an afterthought for a bike. If you can't do it with engine, you are doing it wrong. I have considered a turbo for one of my bikes, but not the FJR.

There is no question that it could be done. You could spend (an exorbitant amount of) time and money and make an FJR1300 engine put out upwards of around 200 hp. Any 1300 cc engine can do that given enough modifications and money. So as a design challenge it could be done.

The more salient question would be: Why bother? You could just start out with a Ninja 1400 that is already so much lighter, and more highly tuned, and isn't carrying all those expensive creature comforts that we all love on a 700 mile day, and that you'd have to throw in the trash, because they all weigh down the bike horribly.

It's really a bunch of pretty simple physics problems to solve:

If you want to be quick, you need high torque and low mass.

If you want to be fast you need good aerodynamics and high horsepower

If you want to be quick and fast you need minimum weight, maximum torque, and maximum horsepower,

And depending on how long the run is going to be, efficient aerodynamics will come into play.

Interesting point. I have a bike that can hang with a ninja 14, and its only 675, but modded to hell. I have built and run/raced the following:

Texas top sportsman: 400 smallblock with 300-200 dual stage nitrous on top, 4.70 1/8 mile breakouts.

586 Supercharged, no nitrous

Street: Grand prix GTP , ported supercharger, full build of a GM 3600, 12.4

Acura legend, headers, chip, 125 shot nitrous, 13.1 (best mod was timing, advance of 31 degrees over stock gave an extra 70 hp)

Chevy 5.3L with supercharger

Corvette LT1, all motor, stock bottom end 420 hp, full suspension, built for road racing (still own)

Ford Lightning, upgraded supercharger, 6 speed conversion

Triumph street triple, daytona cams, full exhaust, weight reduction, custom tune

I have built and raced everything from 6200 lb trucks to 370 lbs bikes. In my mind, the FJR is not a pig.

So, yes, I do have specific goals for a build. I would use the '16 6 speed, with the longer rear gearing spline.

I dont need to hit 1/4 mile times with the FJ, I can do 10 flats or high 9s with my triumph street triple build.

I would like to cruise at 90, at about 4k. I would like it to need minimal maintenance. And be the meanest sport touring on the block

An engine is an air pump. Thermodynamics says you can ignore irrelevant aspects such as fuel when designing. Cam, Intake, Exhaust, or cam mods can only produce more air flow, and more air flow is more power. After that, it is just adding the right fuel quantities and timing the spark.

Polishing the places where air flows sure looks nice, but the results may not be what you expect. A little turbulence can sometimes increase flow volume due to a lot of things that I don't want to understand. Enlarging the ports may help if there is enough material to allow for that, but without a change in valves and/or cams you won't gain much. IMHO, a turbo charger is the best way to go even with all the plumbing. Modern turbo technology has gotten to the point where lag is barely noticeable and the cost is almost reasonable.

Exactly Geezer. I have never seen a quality p&p not result in a gain in HP. Its all about flow control and adding a little turbulence can increase power to a large extent.

Also, I already have some friends working on a new cam profile for me. So there is that.