I'm fairly sure there are a few pilot and aircraft mechanic/builder types on the forum, and they might find my latest project amusing or interesting.

I've been flying since late '84, and airplane ownership has always been a dream of mine. Being just a regular working guy, for all these years I haven't been able to justify or afford the actual purchase of an airplane. And now, I could afford maybe a small single-engine Cessna or Piper...but living in the desert, anything I bought would need to be hangared. Available hangars in this area are hard to find and the monthly rental rates are about the same as my mortgage payment. That's just not going to happen. So my hobby for the past 20 years has been motorcycles, and three of them keep me quite busy with riding and maintenance.

My brother lives in the Houston area and is quite into general aviation, having built his own Vans RV-8. He's also involved in the local Commemorative Air Force wing, where he's the Operations Officer and flies the PT-19 Cornell, T-6 Texan, C-60A Lodestar, and the B-17G Flying Fortress. Outside of the Wing, he's a part owner of a North American T-28A Trojan. It's a cool old airplane, and I've been up in it a few times. It's a bit underpowered with only 800hp to propel 6800 pounds gross weight. He and the other partners have been throwing around the idea of selling the A model and acquiring a big-engine B/C/D model, which has 1425hp to propel 8600 pounds gross weight. It's a significant increase in performance. Also, one of the other partners was a bit of a problem child, and he wasn't going to be invited to participate in the upgrade. They needed a replacement partner to help fund the "new" plane. I raised my hand and said "pick me, pick me!" My brother asked if I was serious or insane...but I had done some math and figured it was do-able. Owning an old warbird is WAY, WAY out of my price range, but when you split the costs among five partners, the cost drops considerably. When I tried to sell my wife on the whole idea, however, she wasn't impressed. She actually said no...I'm already away from home too much with work and motorcycle road trips. If I got in on this deal, she was afraid I'd be gone even more. So I begged and pleaded, and compromises were made. Instead of two week moto tours every spring and fall, I'll just do a fall tour. I can still do shorter rides scattered throughout the year, but no two week spring ride. And I have to take her somewhere for a week or two every July or August just to get away from the oppressive desert heat. Done...she gave me her blessing. I think she should qualify for sainthood.

So we looked around and found a suitable beast:

It's a T-28F Fennec. It started life as a T-28A Trojan, USAF #51-7632, rolling off the production line in 1951. After service with the USAF, it spent some time in storage at the boneyard in Tucson AZ. Meanwhile, in the late '50s, France was involved in a colonial war in Algeria. The French Air Force needed an airplane in a counter-insurgency role, providing air support for French troops on the ground fighting the Algerian resistance. The FAF wanted to purchase big-engine T-28Bs from North American, but the production line was tied up with a large order for the US Navy. The FAF then learned of a company called Pacific Airmotive, which owned the rights to convert T-28As to T-28B configuration, replacing the 800hp Wright R-1300 with the 1425hp Wright R-1820-86B engine, along with various structural modifications. The FAF purchased 148 surplus T-28As out of the boneyard and contracted with Pacific Airmotive to build two prototype conversions. The FAF replaced the Trojan name with Fennec, a small Algerian desert fox. The remaining airframes were shipped to Sud Aviation in St. Nazaire France in 1959. 51-7632 was the first production Fennec to roll off the Sud conversion line.

The airplanes entered combat in late 1960, based in Batna, northern Algeria. Combat operations were short lived, however, and by the end of 1962, the FAF halted further operations and most of the Fennecs returned to France. A total of 23 T-28Fs were lost to accidents or in combat. 51-7632 and 24 others ended up with the Royal Moroccan Air Force in 1965. The RMAF used the T-28s to patrol the troubled border between Morocco and Algeria, occasionally seeing combat during flare-ups along the border. After retirement by the RMAF, 51-7632 and several other Fennecs were sold to the Honduran Air Force. The airplanes weren't shipped by sea, however. They were flown from Morocco to Honduras across the North Atlantic. The guys that flew those old planes across the Atlantic had Big. Brass. Balls. Check out this story of two other Fennecs (not 7632) being ferried across...great story with a lot of great photos: https://www.fightercontrol.co.uk/forum/viewtopic.php?f=18&p=786632 How they navigated at low-level across the water in the days before GPS is beyond me. 51-7632 arrived in Honduras in 1978. I really haven't been able to find what Honduras used the T-28s for, but in 1986, the aircraft was shipped back to the United States. It was reassembled/overhauled and given a desert camouflage paint scheme. The paint job isn't quite authentic for Fennecs in service in Algeria. During their time in combat, the Fennecs were bare metal with a black anti-glare panel painted on the nose. The airplane then traded hands between several owners around the US, and in 2000 it ended up with an owner based in Ramona CA, northeast of San Diego. He last flew it in 2011 before he lost his medical certificate and couldn't fly anymore. He passed away in 2012 and the airplane just sat in a hangar at Ramona collecting dust. Finally, the owner's widow decided that it needed to be sold so someone else could fly and enjoy it.

My brother and I looked at it back in October. It was towed out of the hangar and John started it up. It hadn't flown since 2011 and there was no telling when the last engine run occurred. It needs a lot of work (and $$) to be made airworthy again, but overall it appeared to be a sound airframe. The engine? Well, R-1820s don't like to sit for long periods of time, but hopefully an inspection would turn up no serious issues. Fast forward to January, and the widow called John. She'd had several phone calls about it, mostly tire-kickers. Only one other potential buyer actually came out to look at the plane. The offer he made was a serious lowball. She asked John for a reasonable counter-offer. A deal was made, money was sent as a deposit, and the rest of the partners contributed our funds to an escrow account. In mid-February, the escrow company transferred the funds and I suddenly owned 20% of a T-28. Very strange, but very cool. Actually, I guess I own 20% of the LLC that the plane is now registered to.

Hooking up external power to start the engine:

It's got a really nice cockpit for an old warbird, with 1986 state-of-the-art King avionics. It has a 1997 vintage Garmin GPS mounted on top of the glareshield. The Argus 5000 moving map display is no longer supported and will make a nice paperweight on a desk somewhere.

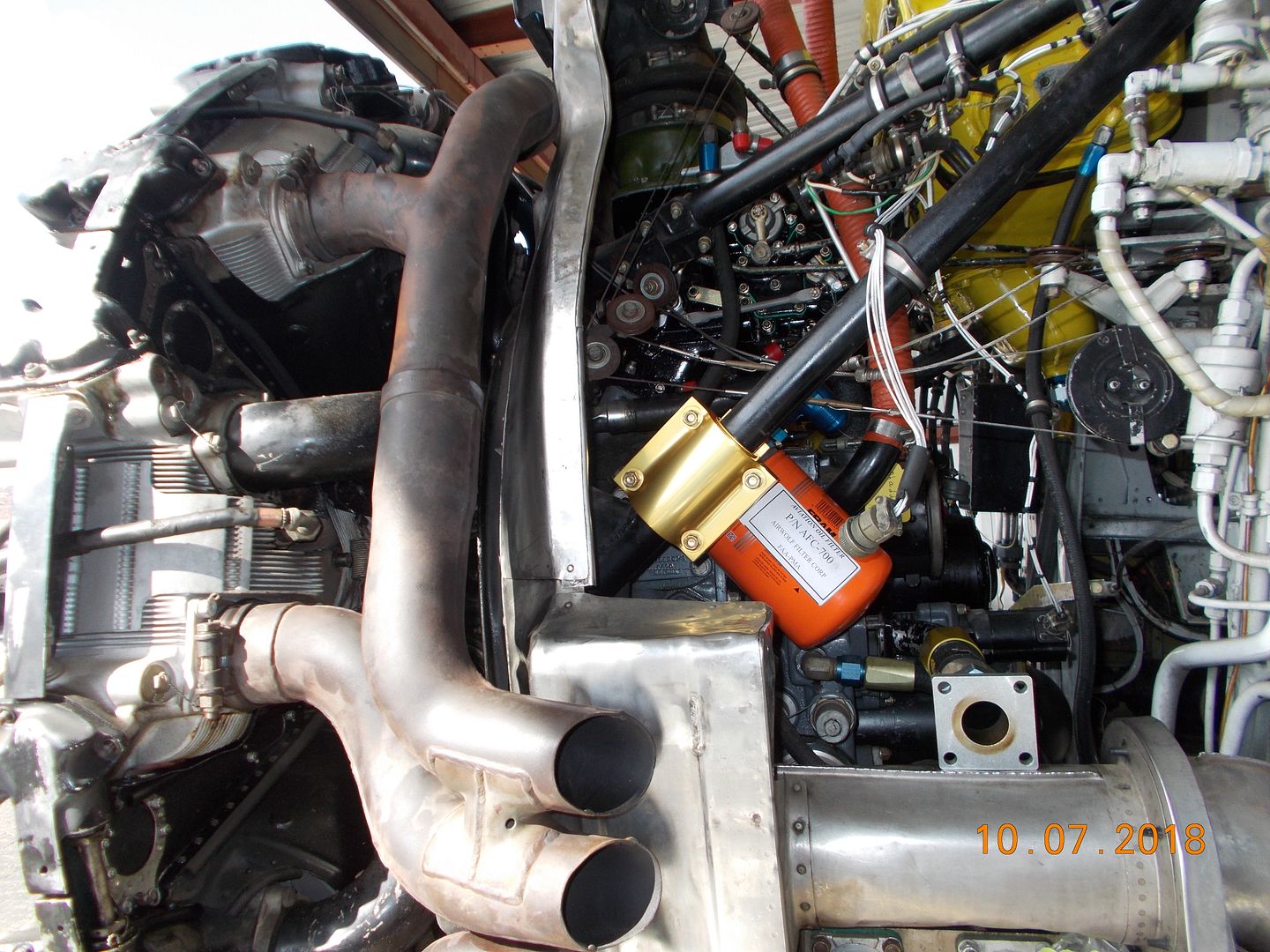

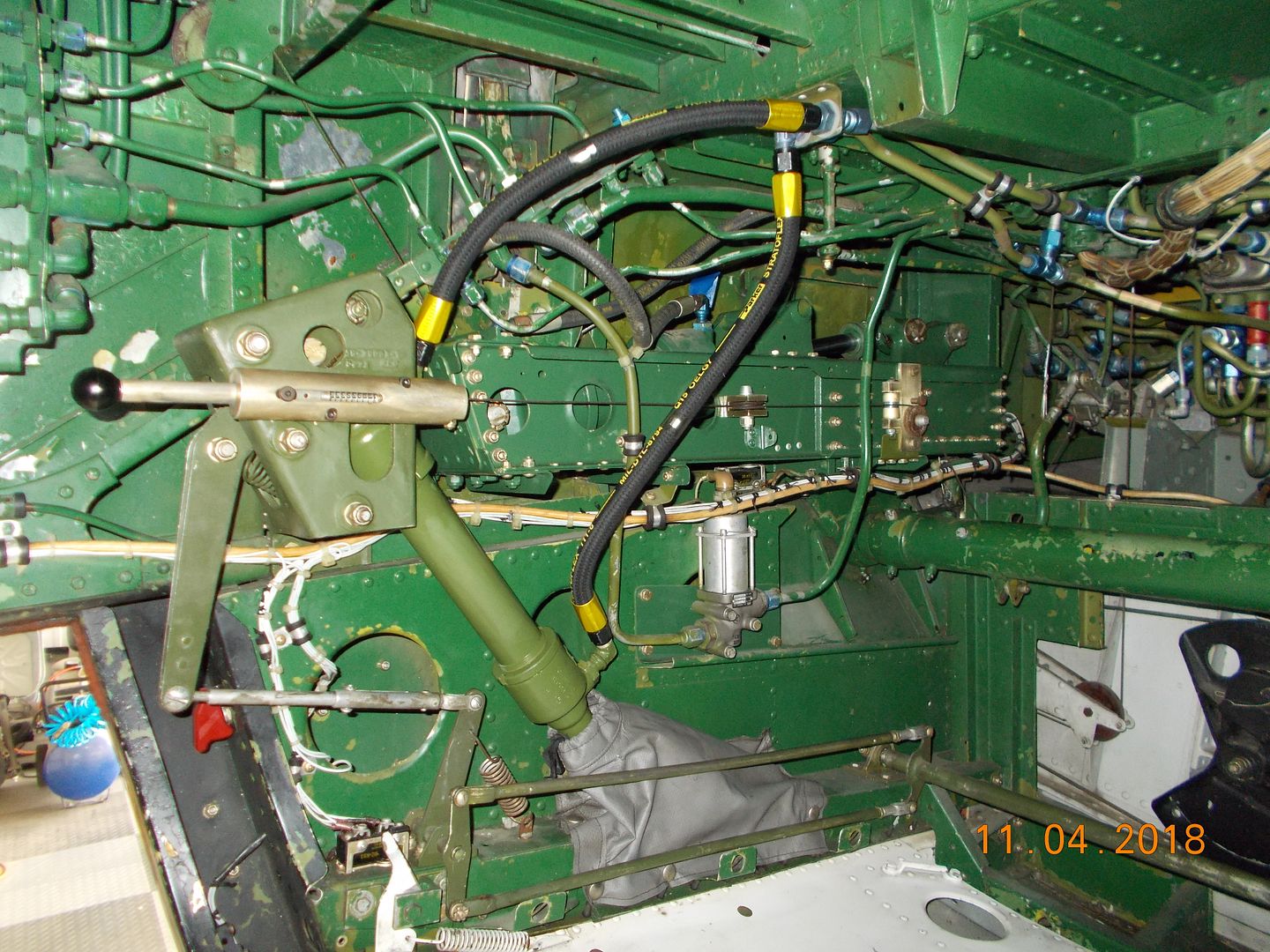

It's been in the shop since mid-February, and we really have no idea when it'll be finished. The guy working on it really knows his stuff, but he's not attacking the problems with as much gusto as we would prefer. The squawk list is pretty long...the prop has to come off for a corrosion inspection/overhaul ($3800), the carburetor needs to be pulled and overhauled ($5600!), new battery and battery conversion kit ($1300), new hoses firewall-forward, oil filter kit installation ($1500), gear struts resealed and pumped up, brake lines replaced, nose gear fork xray/crack inspection, crew oxygen and canopy nitrogen bottles pulled and inspected, fire bottles inspected, and several other smaller items. When it's finished, I'll ride in the back seat while John circles Ramona for a few hours with occasional stops to check the engine oil screens to make sure the engine isn't making metal. If all that goes well, there will be another oil change (8.8 GALLONS of oil, or 35.2 quarts...and it burns 45-50 gallons of avgas per hour, depending on how hard you run it. It ain't cheap to operate), and we'll fly the airplane back to Houston. Then I have to figure out how to get checked out in it. Since it's over 800hp, I'll need a checkride with an FAA designated examiner for the equivalent of a type-rating.

It'll be based in Houston, and I live in California. This is the biggest downside to the whole thing. I'll only get to fly it a few times per year, and that will be around the Houston area and maybe some local airports with a café on the field. If John and I split the flying/expenses, we can take it to Oshkosh. I figure I'll need at least two, preferably three days off each time I head over to fly it. If John is out on a trip, I'll need Uber/car rental to get to the hangar, and a hotel room nearby. That **** adds up quickly! There's absolutely no way to justify the cost vs how much I'll fly it...but, but, it's a T-28!! There's absolutely no other way for me to get into a warbird cockpit where I live, so this is absolutely worth it to me. Like I said before, it's been a dream since I was a little kid.

Thanks Kristi!

I've been flying since late '84, and airplane ownership has always been a dream of mine. Being just a regular working guy, for all these years I haven't been able to justify or afford the actual purchase of an airplane. And now, I could afford maybe a small single-engine Cessna or Piper...but living in the desert, anything I bought would need to be hangared. Available hangars in this area are hard to find and the monthly rental rates are about the same as my mortgage payment. That's just not going to happen. So my hobby for the past 20 years has been motorcycles, and three of them keep me quite busy with riding and maintenance.

My brother lives in the Houston area and is quite into general aviation, having built his own Vans RV-8. He's also involved in the local Commemorative Air Force wing, where he's the Operations Officer and flies the PT-19 Cornell, T-6 Texan, C-60A Lodestar, and the B-17G Flying Fortress. Outside of the Wing, he's a part owner of a North American T-28A Trojan. It's a cool old airplane, and I've been up in it a few times. It's a bit underpowered with only 800hp to propel 6800 pounds gross weight. He and the other partners have been throwing around the idea of selling the A model and acquiring a big-engine B/C/D model, which has 1425hp to propel 8600 pounds gross weight. It's a significant increase in performance. Also, one of the other partners was a bit of a problem child, and he wasn't going to be invited to participate in the upgrade. They needed a replacement partner to help fund the "new" plane. I raised my hand and said "pick me, pick me!" My brother asked if I was serious or insane...but I had done some math and figured it was do-able. Owning an old warbird is WAY, WAY out of my price range, but when you split the costs among five partners, the cost drops considerably. When I tried to sell my wife on the whole idea, however, she wasn't impressed. She actually said no...I'm already away from home too much with work and motorcycle road trips. If I got in on this deal, she was afraid I'd be gone even more. So I begged and pleaded, and compromises were made. Instead of two week moto tours every spring and fall, I'll just do a fall tour. I can still do shorter rides scattered throughout the year, but no two week spring ride. And I have to take her somewhere for a week or two every July or August just to get away from the oppressive desert heat. Done...she gave me her blessing. I think she should qualify for sainthood.

So we looked around and found a suitable beast:

It's a T-28F Fennec. It started life as a T-28A Trojan, USAF #51-7632, rolling off the production line in 1951. After service with the USAF, it spent some time in storage at the boneyard in Tucson AZ. Meanwhile, in the late '50s, France was involved in a colonial war in Algeria. The French Air Force needed an airplane in a counter-insurgency role, providing air support for French troops on the ground fighting the Algerian resistance. The FAF wanted to purchase big-engine T-28Bs from North American, but the production line was tied up with a large order for the US Navy. The FAF then learned of a company called Pacific Airmotive, which owned the rights to convert T-28As to T-28B configuration, replacing the 800hp Wright R-1300 with the 1425hp Wright R-1820-86B engine, along with various structural modifications. The FAF purchased 148 surplus T-28As out of the boneyard and contracted with Pacific Airmotive to build two prototype conversions. The FAF replaced the Trojan name with Fennec, a small Algerian desert fox. The remaining airframes were shipped to Sud Aviation in St. Nazaire France in 1959. 51-7632 was the first production Fennec to roll off the Sud conversion line.

The airplanes entered combat in late 1960, based in Batna, northern Algeria. Combat operations were short lived, however, and by the end of 1962, the FAF halted further operations and most of the Fennecs returned to France. A total of 23 T-28Fs were lost to accidents or in combat. 51-7632 and 24 others ended up with the Royal Moroccan Air Force in 1965. The RMAF used the T-28s to patrol the troubled border between Morocco and Algeria, occasionally seeing combat during flare-ups along the border. After retirement by the RMAF, 51-7632 and several other Fennecs were sold to the Honduran Air Force. The airplanes weren't shipped by sea, however. They were flown from Morocco to Honduras across the North Atlantic. The guys that flew those old planes across the Atlantic had Big. Brass. Balls. Check out this story of two other Fennecs (not 7632) being ferried across...great story with a lot of great photos: https://www.fightercontrol.co.uk/forum/viewtopic.php?f=18&p=786632 How they navigated at low-level across the water in the days before GPS is beyond me. 51-7632 arrived in Honduras in 1978. I really haven't been able to find what Honduras used the T-28s for, but in 1986, the aircraft was shipped back to the United States. It was reassembled/overhauled and given a desert camouflage paint scheme. The paint job isn't quite authentic for Fennecs in service in Algeria. During their time in combat, the Fennecs were bare metal with a black anti-glare panel painted on the nose. The airplane then traded hands between several owners around the US, and in 2000 it ended up with an owner based in Ramona CA, northeast of San Diego. He last flew it in 2011 before he lost his medical certificate and couldn't fly anymore. He passed away in 2012 and the airplane just sat in a hangar at Ramona collecting dust. Finally, the owner's widow decided that it needed to be sold so someone else could fly and enjoy it.

My brother and I looked at it back in October. It was towed out of the hangar and John started it up. It hadn't flown since 2011 and there was no telling when the last engine run occurred. It needs a lot of work (and $$) to be made airworthy again, but overall it appeared to be a sound airframe. The engine? Well, R-1820s don't like to sit for long periods of time, but hopefully an inspection would turn up no serious issues. Fast forward to January, and the widow called John. She'd had several phone calls about it, mostly tire-kickers. Only one other potential buyer actually came out to look at the plane. The offer he made was a serious lowball. She asked John for a reasonable counter-offer. A deal was made, money was sent as a deposit, and the rest of the partners contributed our funds to an escrow account. In mid-February, the escrow company transferred the funds and I suddenly owned 20% of a T-28. Very strange, but very cool. Actually, I guess I own 20% of the LLC that the plane is now registered to.

Hooking up external power to start the engine:

It's got a really nice cockpit for an old warbird, with 1986 state-of-the-art King avionics. It has a 1997 vintage Garmin GPS mounted on top of the glareshield. The Argus 5000 moving map display is no longer supported and will make a nice paperweight on a desk somewhere.

It's been in the shop since mid-February, and we really have no idea when it'll be finished. The guy working on it really knows his stuff, but he's not attacking the problems with as much gusto as we would prefer. The squawk list is pretty long...the prop has to come off for a corrosion inspection/overhaul ($3800), the carburetor needs to be pulled and overhauled ($5600!), new battery and battery conversion kit ($1300), new hoses firewall-forward, oil filter kit installation ($1500), gear struts resealed and pumped up, brake lines replaced, nose gear fork xray/crack inspection, crew oxygen and canopy nitrogen bottles pulled and inspected, fire bottles inspected, and several other smaller items. When it's finished, I'll ride in the back seat while John circles Ramona for a few hours with occasional stops to check the engine oil screens to make sure the engine isn't making metal. If all that goes well, there will be another oil change (8.8 GALLONS of oil, or 35.2 quarts...and it burns 45-50 gallons of avgas per hour, depending on how hard you run it. It ain't cheap to operate), and we'll fly the airplane back to Houston. Then I have to figure out how to get checked out in it. Since it's over 800hp, I'll need a checkride with an FAA designated examiner for the equivalent of a type-rating.

It'll be based in Houston, and I live in California. This is the biggest downside to the whole thing. I'll only get to fly it a few times per year, and that will be around the Houston area and maybe some local airports with a café on the field. If John and I split the flying/expenses, we can take it to Oshkosh. I figure I'll need at least two, preferably three days off each time I head over to fly it. If John is out on a trip, I'll need Uber/car rental to get to the hangar, and a hotel room nearby. That **** adds up quickly! There's absolutely no way to justify the cost vs how much I'll fly it...but, but, it's a T-28!! There's absolutely no other way for me to get into a warbird cockpit where I live, so this is absolutely worth it to me. Like I said before, it's been a dream since I was a little kid.

Thanks Kristi!