fastpappy

Well-known member

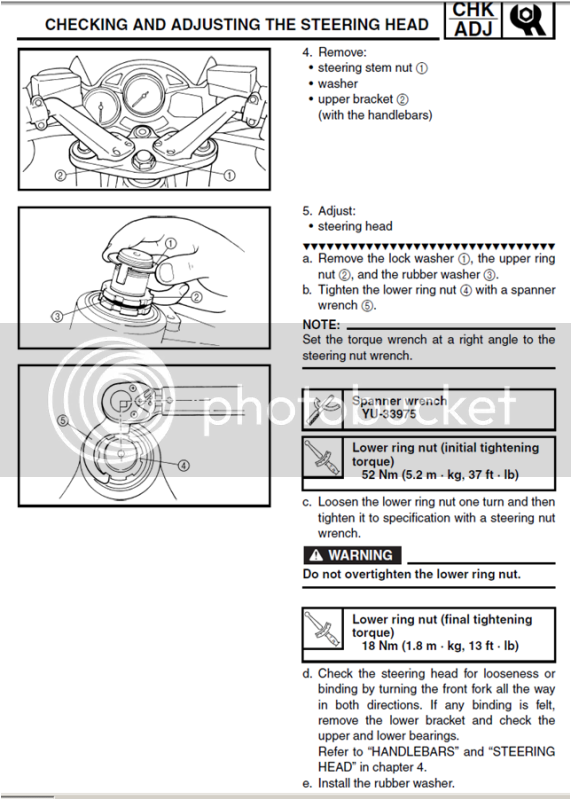

Ok it's official I must be an ***** since I can't seem to find it though I've tried all the searchs. And I know I must have read it a half dozen times but I can't find the step by step on torqueing the steering head bearing. Anyone got a link?? :dribble: