hppants

Well-known member

It's time to check, re-grease, and re-torque my sterring stem assy. I don't have any notchy feeling in the bars, but at 11K it's never been done to my knowledge, and that makes it past due.

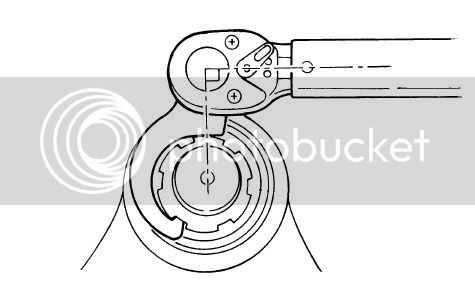

Buying the Yamaha spanner wrench for the lower nut will be both expensive and time consuming. Surely, someone has bought this tool from a readily available supplier? If so, would you share your source?

I've read the "How to" on FJRinfo.com. Seems pretty straight forward, but any other tips/suggestions would be appreciated.

Buying the Yamaha spanner wrench for the lower nut will be both expensive and time consuming. Surely, someone has bought this tool from a readily available supplier? If so, would you share your source?

I've read the "How to" on FJRinfo.com. Seems pretty straight forward, but any other tips/suggestions would be appreciated.