TownsendsFJR1300

Well-known member

Ok, how does lifting the tank show a clogged injector?He lifted the tank?Do you know how he found the clogged injector on the bike? TIA, Scott

Ok, how does lifting the tank show a clogged injector?He lifted the tank?Do you know how he found the clogged injector on the bike? TIA, Scott

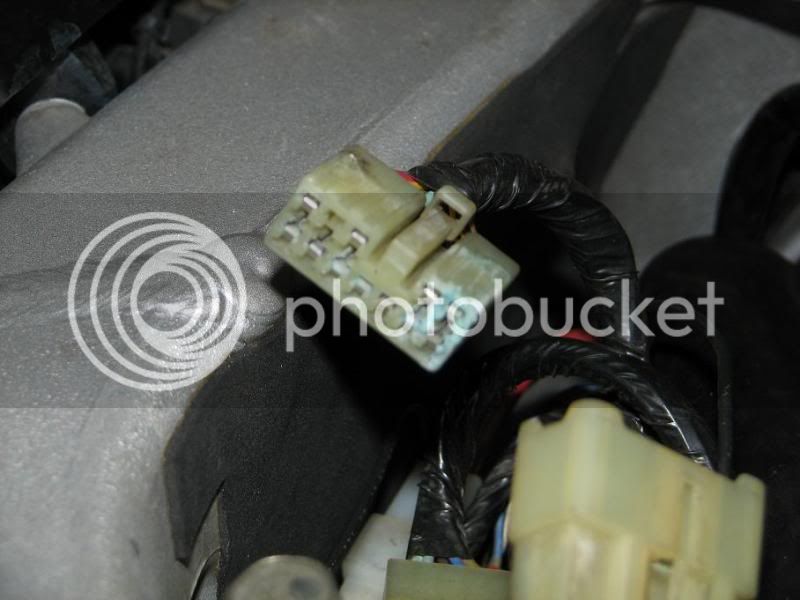

:yahoo: :yahoo: :yahoo:Faster,Did you check out your Main Wiring Harness Connector?

Looks Like Silver wins the prize

onnector A is corroded:

I'll start cleaning them tonight after work ....

Other than "scraping" with a small pick, any and all other suggestions on how to get all that crud out of my connectors would be greatly appreciated !Thats easily 3 times worse than mine when mine started acting up..... I'm surprised it still ran... Make sure you put lots of dilectric grease in there, no more corrosion after that....

Can't find the injectors unless you lift the tank. Thought that was fairly obvious. :finger:Ok, how does lifting the tank show a clogged injector?He lifted the tank?Do you know how he found the clogged injector on the bike? TIA, Scott

Get a can of spray contact cleaner from Rat Shack, then plug-unplug-plug-unplug and repeat about 2000 times, with repeat sprayings until the goop is gone.Other than "scraping" with a small pick, any and all other suggestions on how to get all that crud out of my connectors would be greatly appreciated !Thats easily 3 times worse than mine when mine started acting up..... I'm surprised it still ran... Make sure you put lots of dilectric grease in there, no more corrosion after that....

I know where the injectors are, having done several syncs myself on it as well as a throttle spring un-wind. I guess you don't know either how to ACTUALLY check an injector (IE is it done on the bike running, just removing and sending out to a shop, etc).Can't find the injectors unless you lift the tank. Thought that was fairly obvious. :finger:Ok, how does lifting the tank show a clogged injector?He lifted the tank?Do you know how he found the clogged injector on the bike? TIA, Scott

![fjackets Real Lambskin Leather Biker Jacket — Quilted Cafe Racer Zip Up Moto Leather Jackets For Men | [1100085] Johnson Brown, XL](https://m.media-amazon.com/images/I/41I7Pm1f+vL._SL500_.jpg)

As posted above pick at it, if you have an air compressor and WD40 should help loosen it. I believe I used an old tooth brush to help loosen the crud. It got into most of the nooks and crannies....Other than "scraping" with a small pick, any and all other suggestions on how to get all that crud out of my connectors would be greatly appreciated !Thats easily 3 times worse than mine when mine started acting up..... I'm surprised it still ran... Make sure you put lots of dilectric grease in there, no more corrosion after that....

That would be an incorrect guess.I guess you don't know either how to ACTUALLY check an injector

That would be an incorrect guess.I guess you don't know either how to ACTUALLY check an injector

To check the injectors for operation, you would have to pull the tank and remove each injector from the fuel rail, leaving the injectors plugged in to the wiring harness.

Then, after entering the DIAG mode through the instrument cluster, you would first put the kill switch into the OFF mode, then cycle the DIAG readout up to #36. Turn the kill switch back to the normal RUN position and fuel will come squirting out of the #1 injector. The injector will pulse and spray fuel 5 times per second until you switch the kill switch back off.

Cycle up to #37 and repeat for injector #2, #38 for injector #3 and #39 for injector #4.

Visually compare the fuel flow from each injector as you cycle up and down the DIAG codes. A clogged injector will be display an obviously different fuel flow from an un-clogged injector. Unclogged will give you a nice big spray of fuel. A clogged injector will either not flow any fuel, or just let fuel dribble out the end of the injector.

(shuffling feet, looking a bit embarassed.....)That would be an incorrect guess.I guess you don't know either how to ACTUALLY check an injector

To check the injectors for operation, you would have to pull the tank and remove each injector from the fuel rail, leaving the injectors plugged in to the wiring harness.

Then, after entering the DIAG mode through the instrument cluster, you would first put the kill switch into the OFF mode, then cycle the DIAG readout up to #36. Turn the kill switch back to the normal RUN position and fuel will come squirting out of the #1 injector. The injector will pulse and spray fuel 5 times per second until you switch the kill switch back off.

Cycle up to #37 and repeat for injector #2, #38 for injector #3 and #39 for injector #4.

Visually compare the fuel flow from each injector as you cycle up and down the DIAG codes. A clogged injector will be display an obviously different fuel flow from an un-clogged injector. Unclogged will give you a nice big spray of fuel. A clogged injector will either not flow any fuel, or just let fuel dribble out the end of the injector.

Thank you, thats what I wanted to know... I have a four stroke FI 150 HP Yamaha outboard that may have had FI problems. Short of replacing each(or sending them off for cleaning) I wanted to know.

I take it with the injector(s) disconnected from the fuel rail, there's enough fuel in them to see their performance when activated?

Look RH, somebody thought you were being serious!!!!How often does that happen??!?! You have to improve your use of smilies.

(Here it comes . . . . .)

Loose on which end - plug or coil ?Coil Wireshttps://www.fjrforum.com/forum//index.php?s...st&p=714281

Possible Loose Coil Wire to Plug Boot Wire where you could trim off about 1/4" and reinstall.

Enter your email address to join: