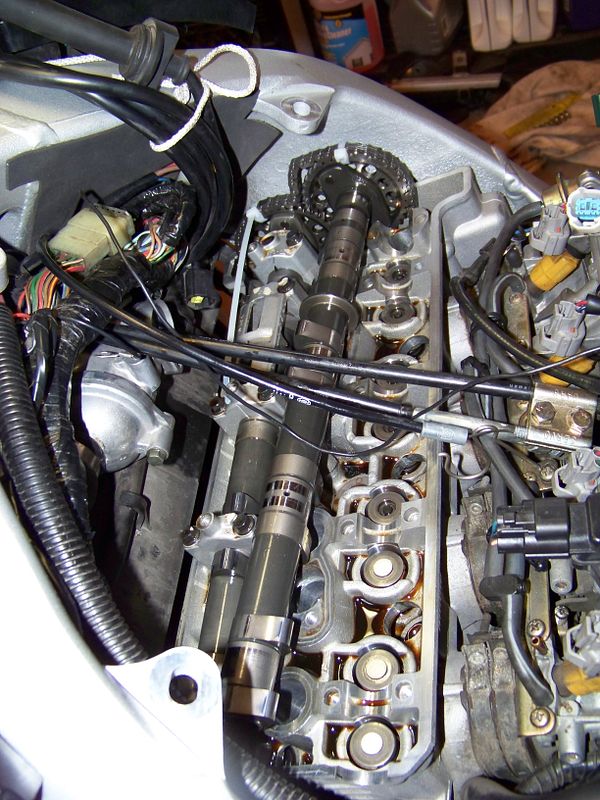

So I went ahead and did the valve check on my own. SO freaked out that I invited a "bunch of bikers" to the house so I cancelled the tech section I had planned. Valve-check proceeded without incident except that everything is kinda tight. All exhaust valves are .200 except for cylinder 4 which is .180. Intakes are all .150 again except for cylinder 4 which is .138. I tried to lift the intake cam, but since cylinder 4 is next to the crank (and I didn't want to let the cam chain loose) I couldn't get enough clearance to remove the riser and change the shim. I'm gonna find me a local mechanic and make him let me participate in the operation. I changed the CCT, but the original was perfect. 46000 miles and the engine was always quiet.

So everything is kinda tight. I'd like the exhausts to be around .220 and the intakes at .180. So yea, I'd like to re-shim the entire freaking thing.

Questions: the CCT I bought is a green dot (not blue). It doesn't lock into a retracted position. I don't think it matters, but what'd a y'all think. 2. Is it horrible that I continue to ride with the intake on 4 so tight? Am I going to do any damage if I run the motor for a week or two before I change the shims?

Dats it. Thanks all! Baz

So everything is kinda tight. I'd like the exhausts to be around .220 and the intakes at .180. So yea, I'd like to re-shim the entire freaking thing.

Questions: the CCT I bought is a green dot (not blue). It doesn't lock into a retracted position. I don't think it matters, but what'd a y'all think. 2. Is it horrible that I continue to ride with the intake on 4 so tight? Am I going to do any damage if I run the motor for a week or two before I change the shims?

Dats it. Thanks all! Baz

![fjackets Real Lambskin Leather Biker Jacket — Quilted Cafe Racer Zip Up Moto Leather Jackets For Men | [1100085] Johnson Brown, XL](https://m.media-amazon.com/images/I/41I7Pm1f+vL._SL500_.jpg)