Good Morning Fellow FJR Owners and Lords of Engine Nomenclature... Doug and I got busy with the engine this past Saturday. Um ok, not in THAT way.

BUT some of you may consider the following to be Engine pR0n - er something like that.

The conditions were just right. I am very blessed with the real estate (basement) to do this project. But I'm doubly blessed to have a friend like Doug! I'll explain as I go.

So Let's GO!

When I left you last, Doug was applying my feeble air tire inflater on the the stuck bolt. The pinch bolt was taken care of and the PB Blaster was applied over multiple days. A week went by. It's Saturday and my thoughts are on motorcycles (like always), specifically my naked and ailing FJR in the basement. But! I'm doing my household duties and am at the grocery store. Taking care of the weeks shopping. I get a text from the Wife "Hey how far r u out? Doug is here." My response is "about 10 minutes... just ready to check out." Well, the lunch meat lady was taking her time and it was more like 15 before I got home.

Doug and my wife were chatting it up mostly on work stuff (we work at the same place). Wife says "I'll put away the groceries, you and Doug do downstairs."

OK!

We head downstairs and I see.....

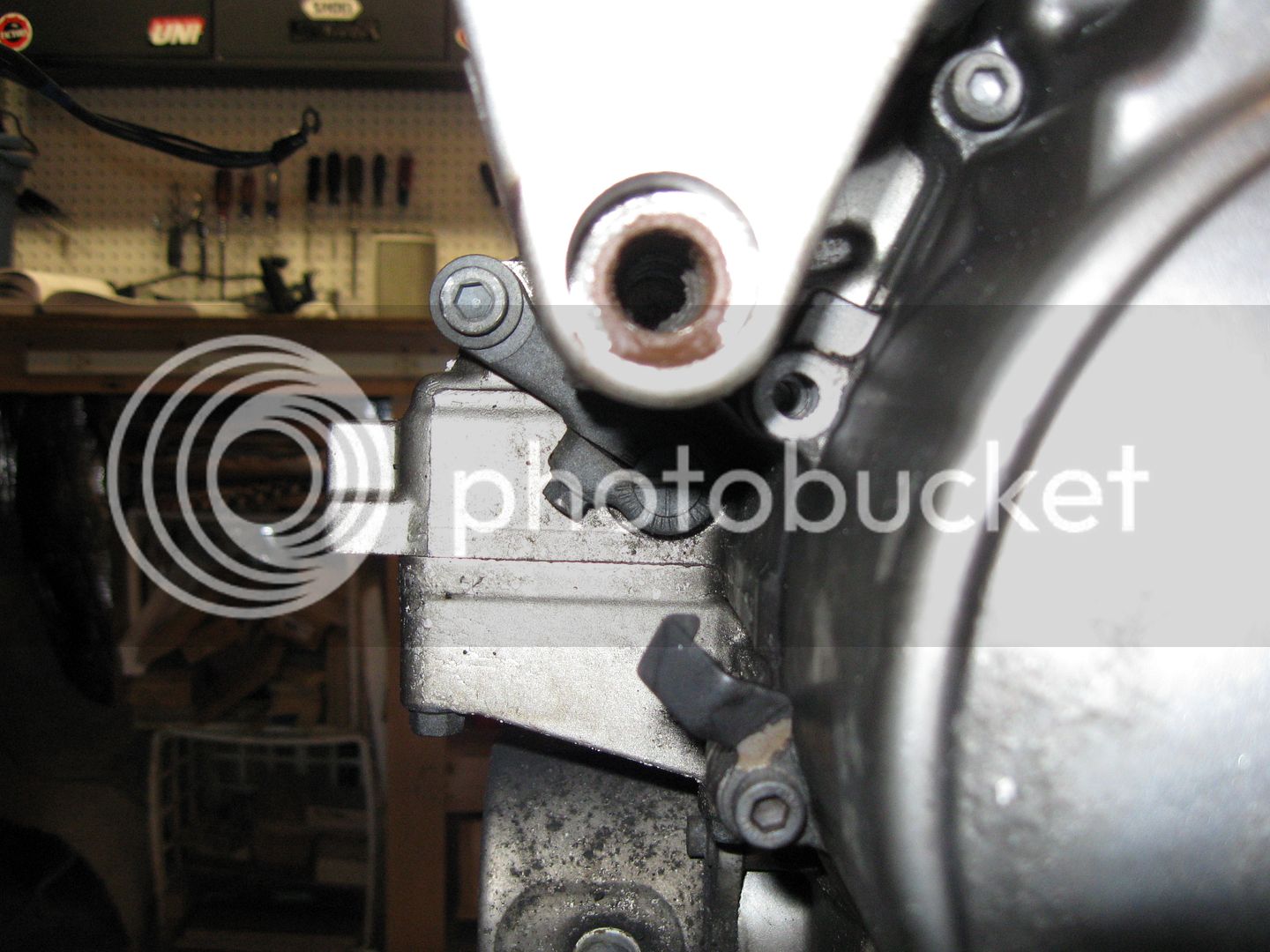

Doug's grinning and now so am I! He heated it up some more and just kept applying pressure and it started to give. Back slightly and forward more.... He's thinking "It's either coming out or it's going to break!" Thankfully it was coming out!

That's all the help Doug could render that day. He had a wedding to attend to.

Here's the offending member in it's all of it's Grungy Splendor!

A little wire wheel loving on that guy with some appropriate grease and it'll be good as new! I still have yet to separate the spacer, bolt and slider.

Fast forward another weekend to this past Saturday.....

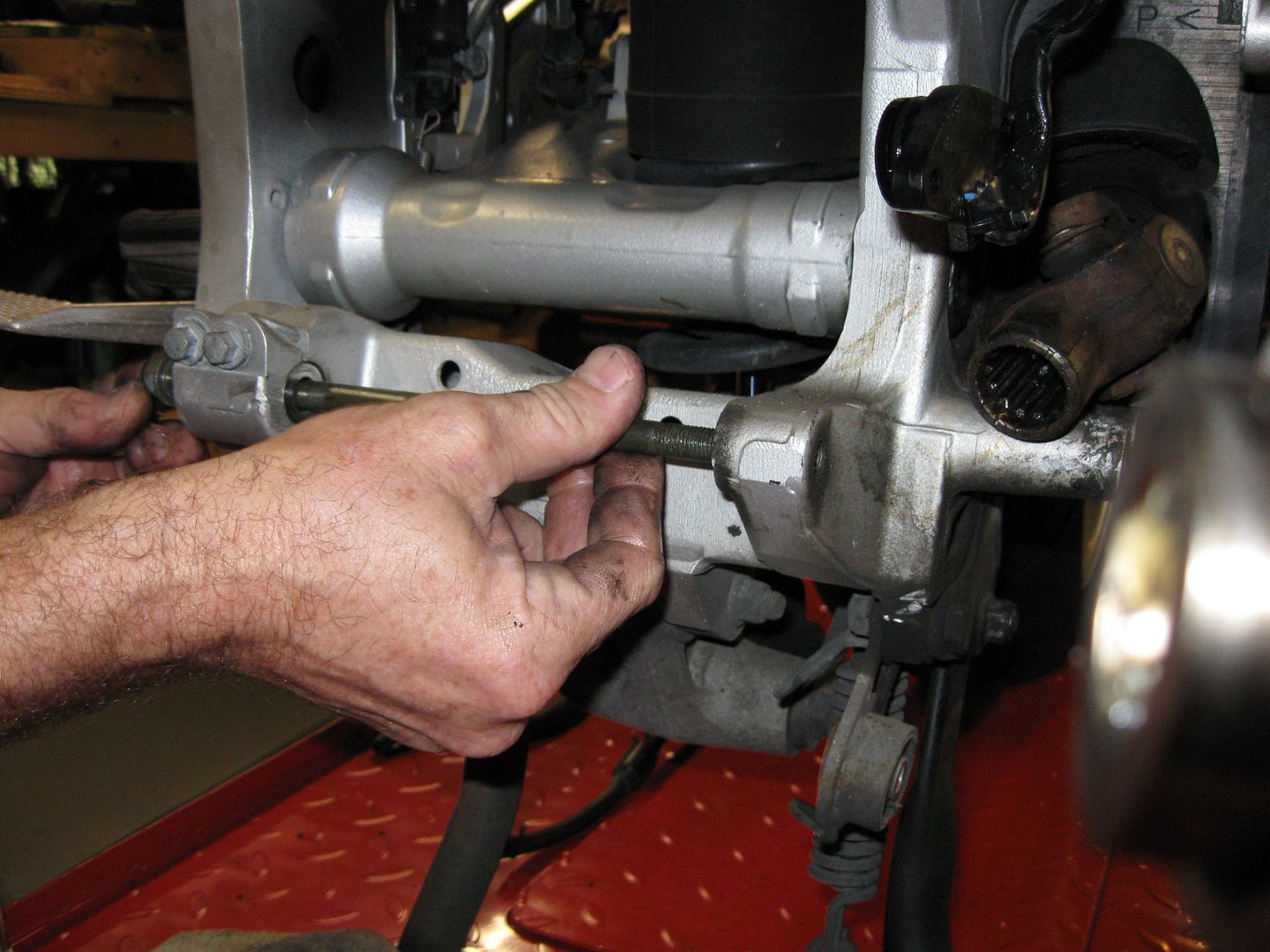

Whoa now. We have movement!

Here's where Shutterbug Streethawk has put down the camera and help! We had to get my wife involved as well. She's a Tropper and was more than willing to move the jack out the way while Doug and I lifted the engine and carried it over to it's resting place. (note: I offered the bench but Doug said "Floor is good. That way if something falls, it won't have far to go."

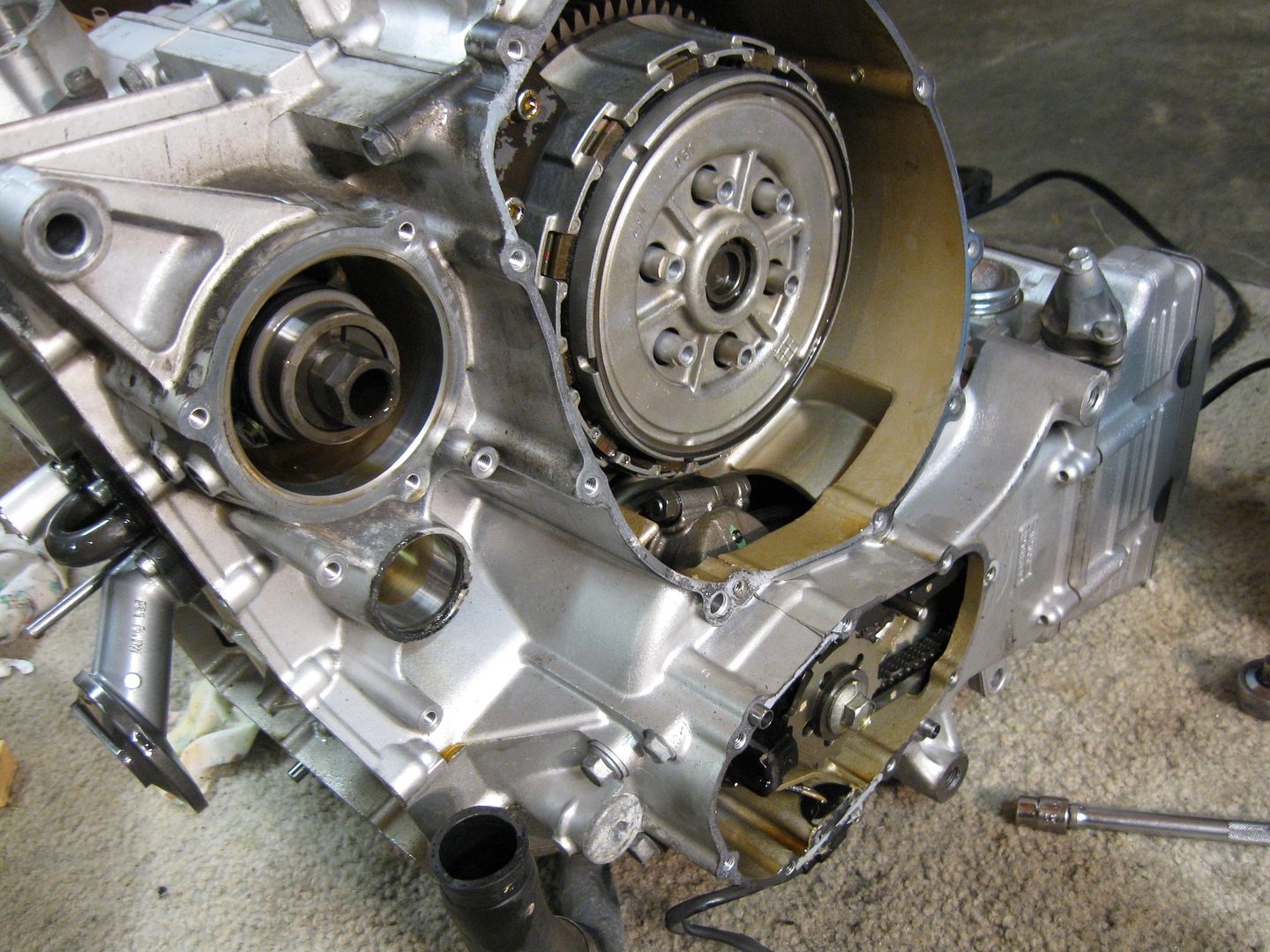

So without further fanfare (because there wasn't any):

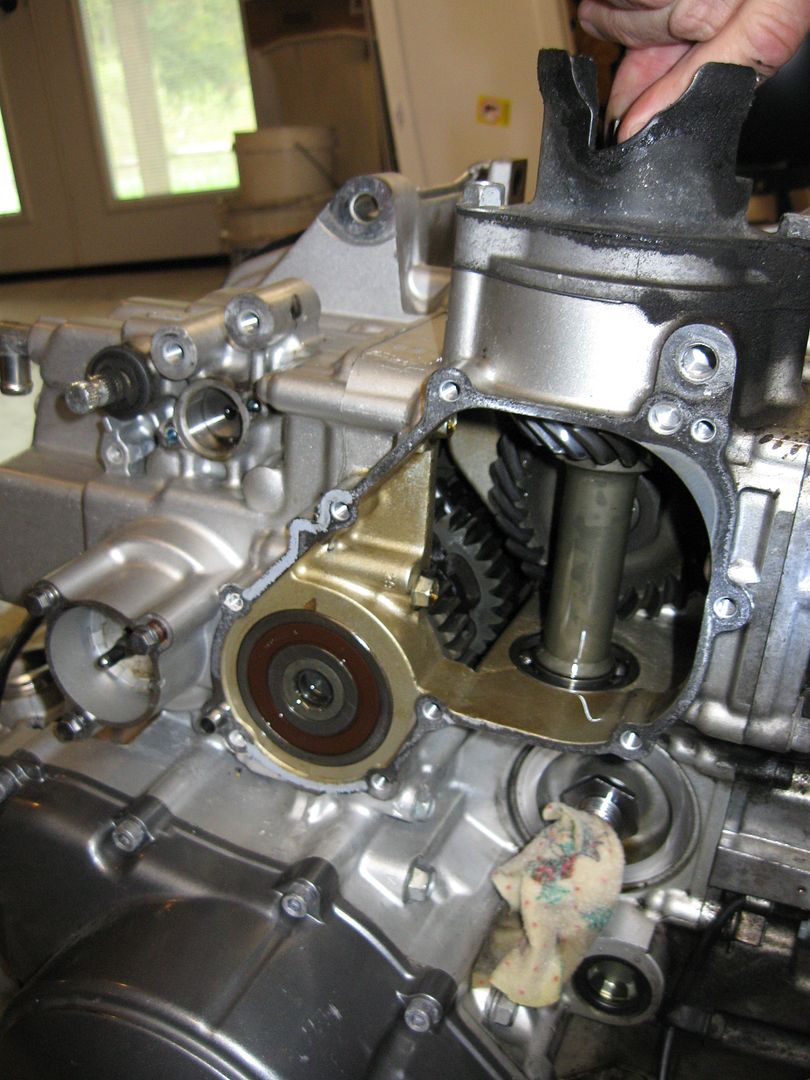

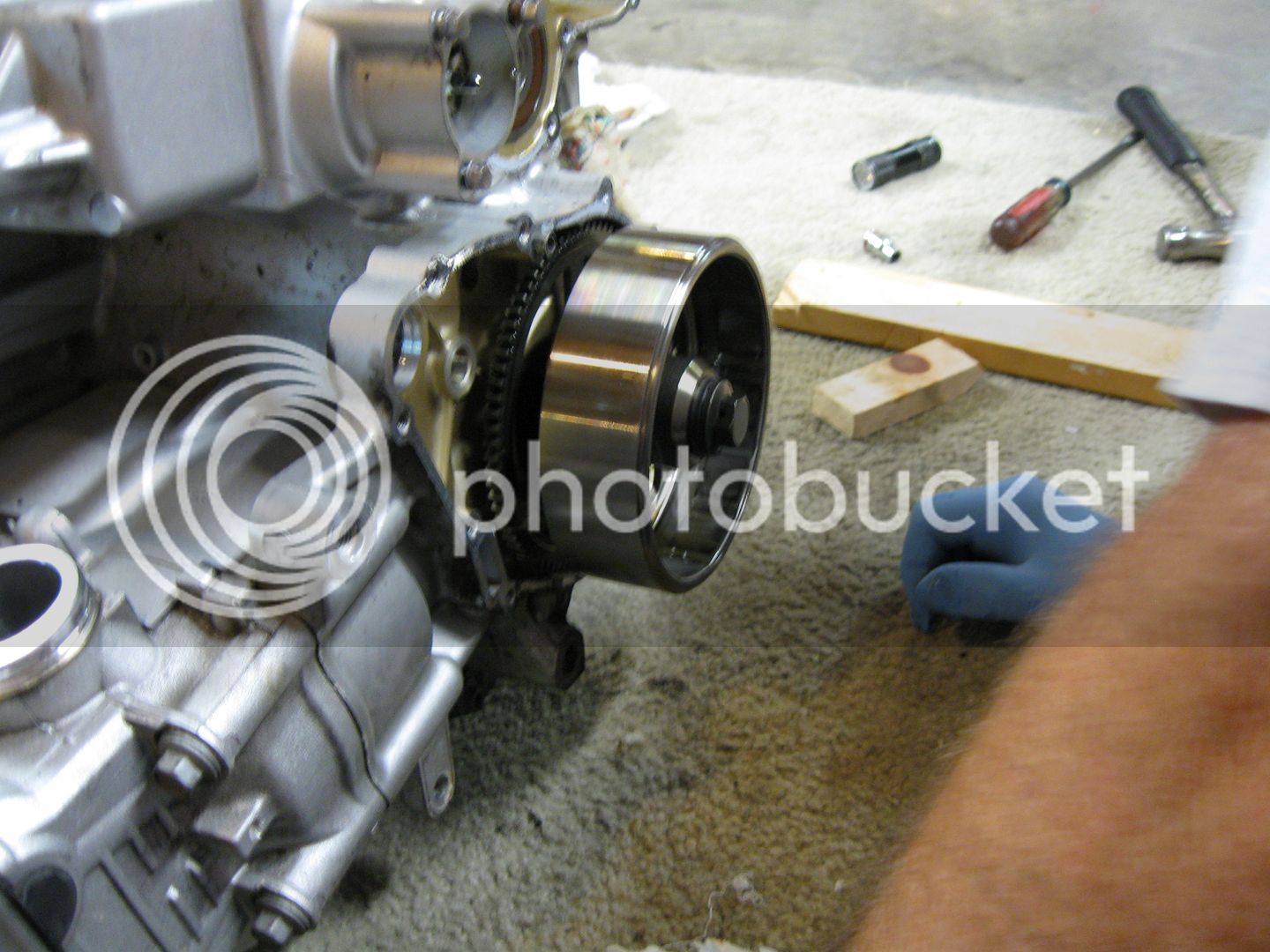

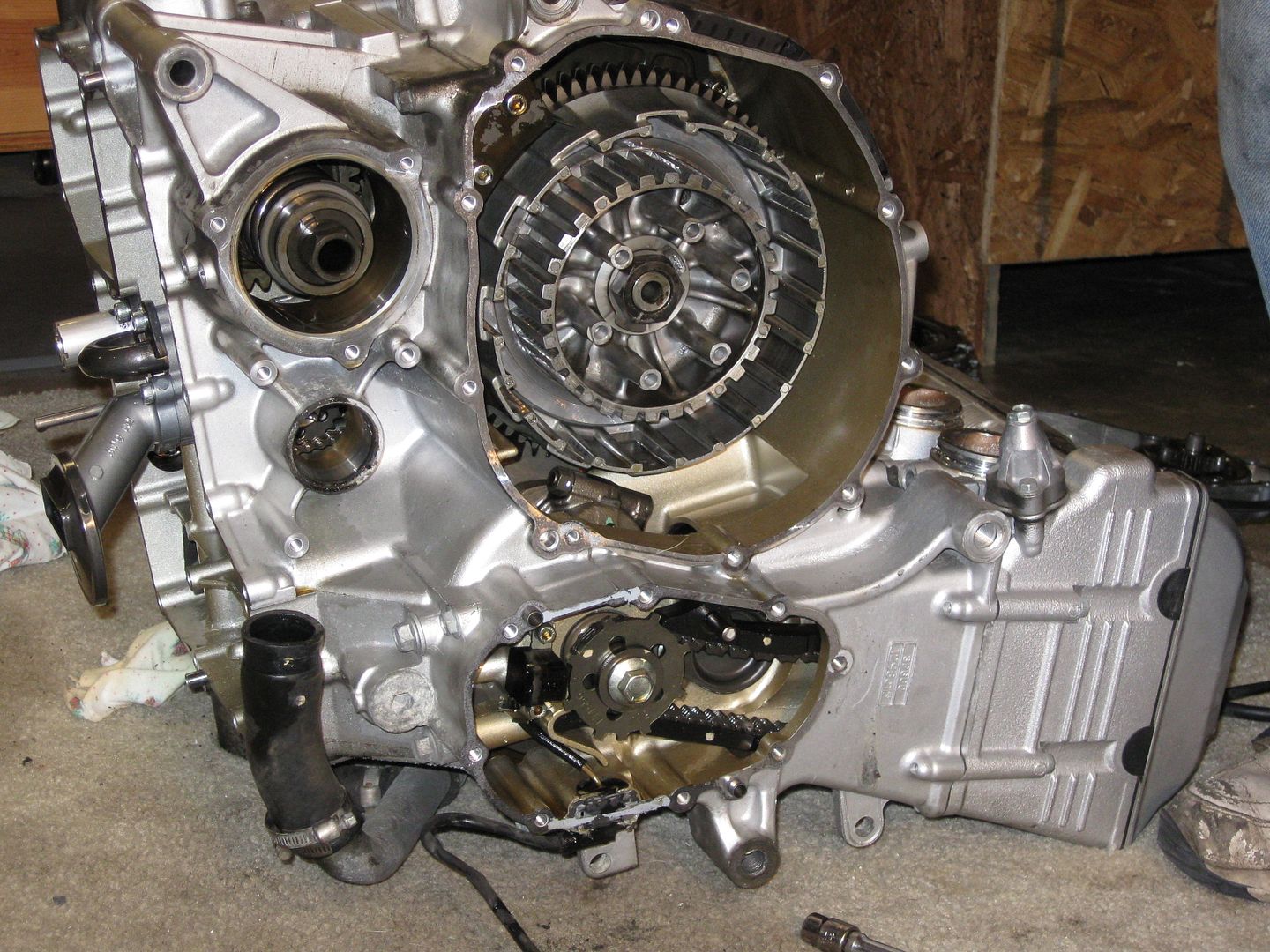

There she is! 1300 CCs and the heart of the FJR Goodness!!

Now some shots of the frame and mounting areas etc... Most of this is displayed for Academics. Besides that annoying bolt, there's no damage, issues or any other problems outside the engine.

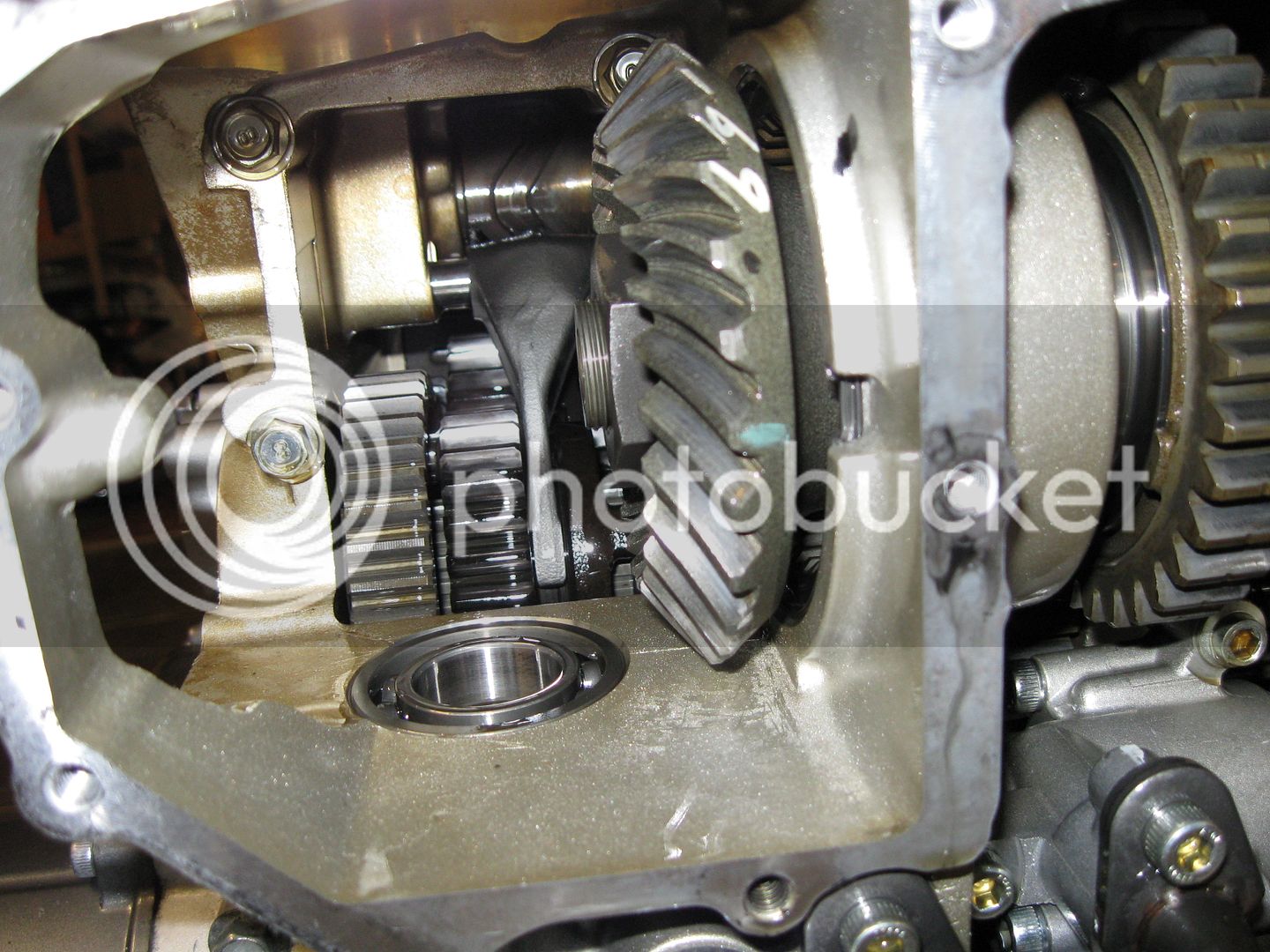

Lower mount area.

This bolt is threaded on one side.

Upper frame. It's interesting how they pad the spars to keep the engine and other stuff from scraping.

My Wife had a cool comment about the frame. "It's amazing how far they've come on the design of motorcycle frames. (Then the more Stereotypical follow up) They're quite pretty!" Wive's have their moments!

Mine is smarter than me AND rides, so I consider myself Lucky!

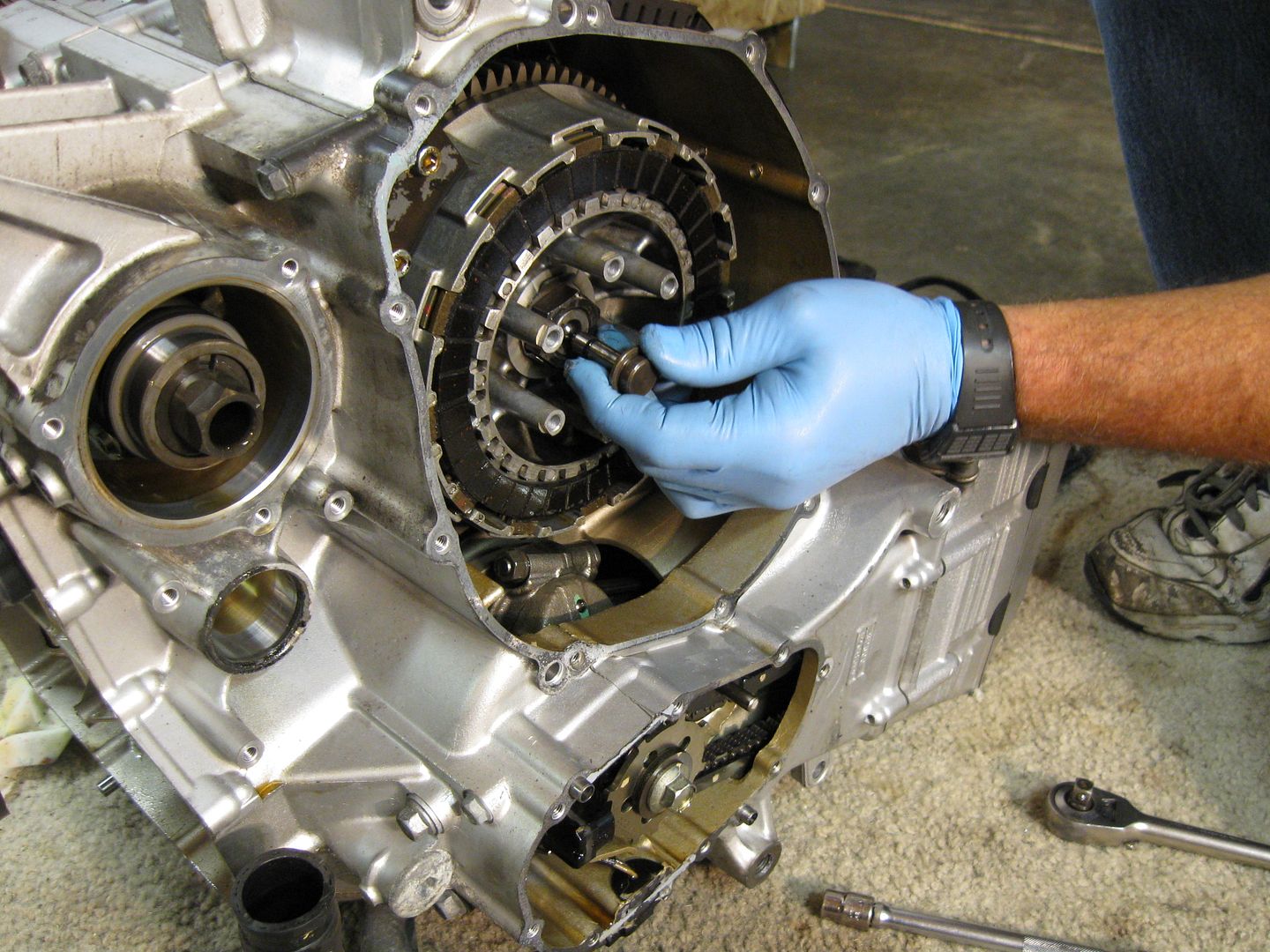

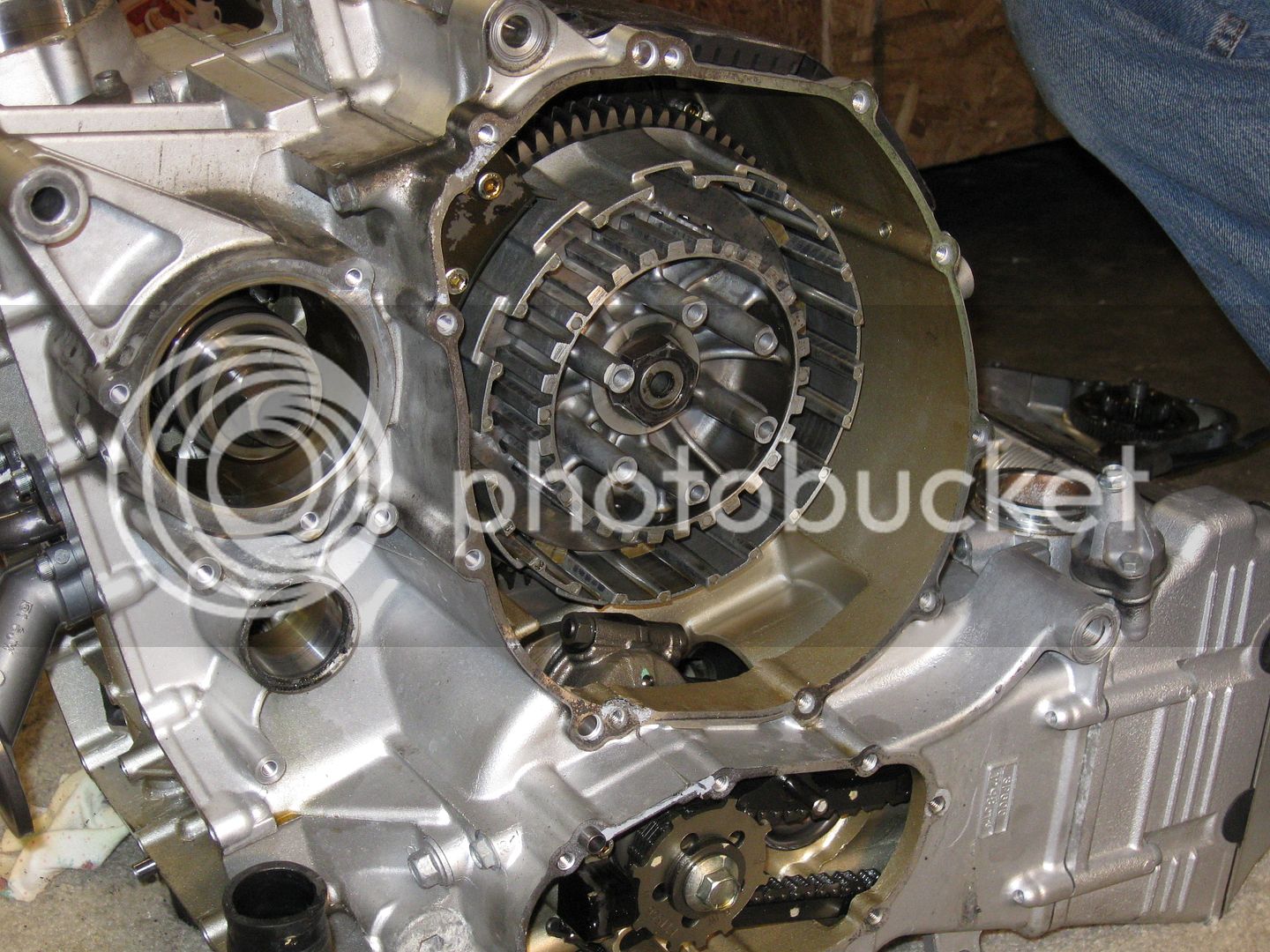

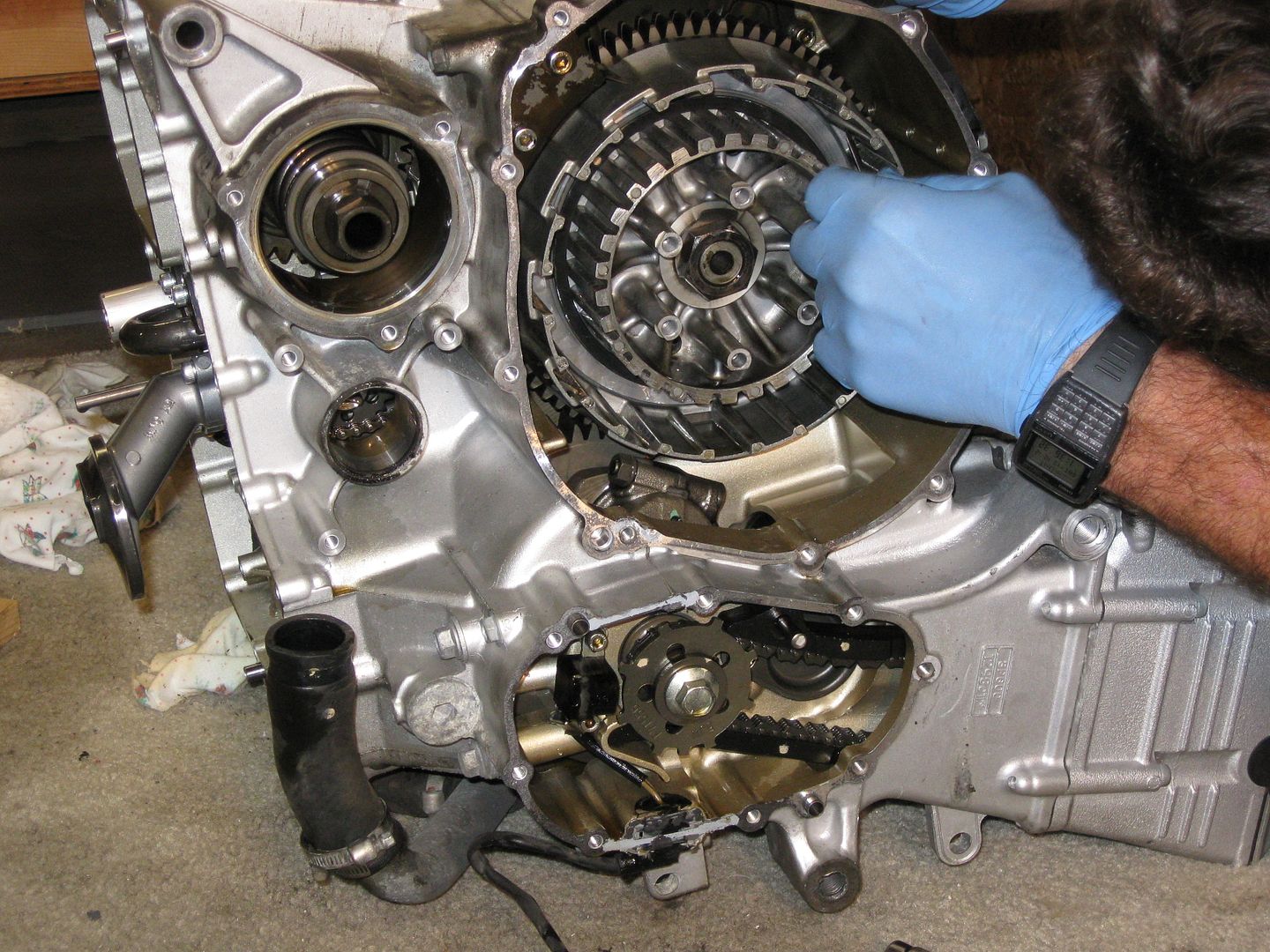

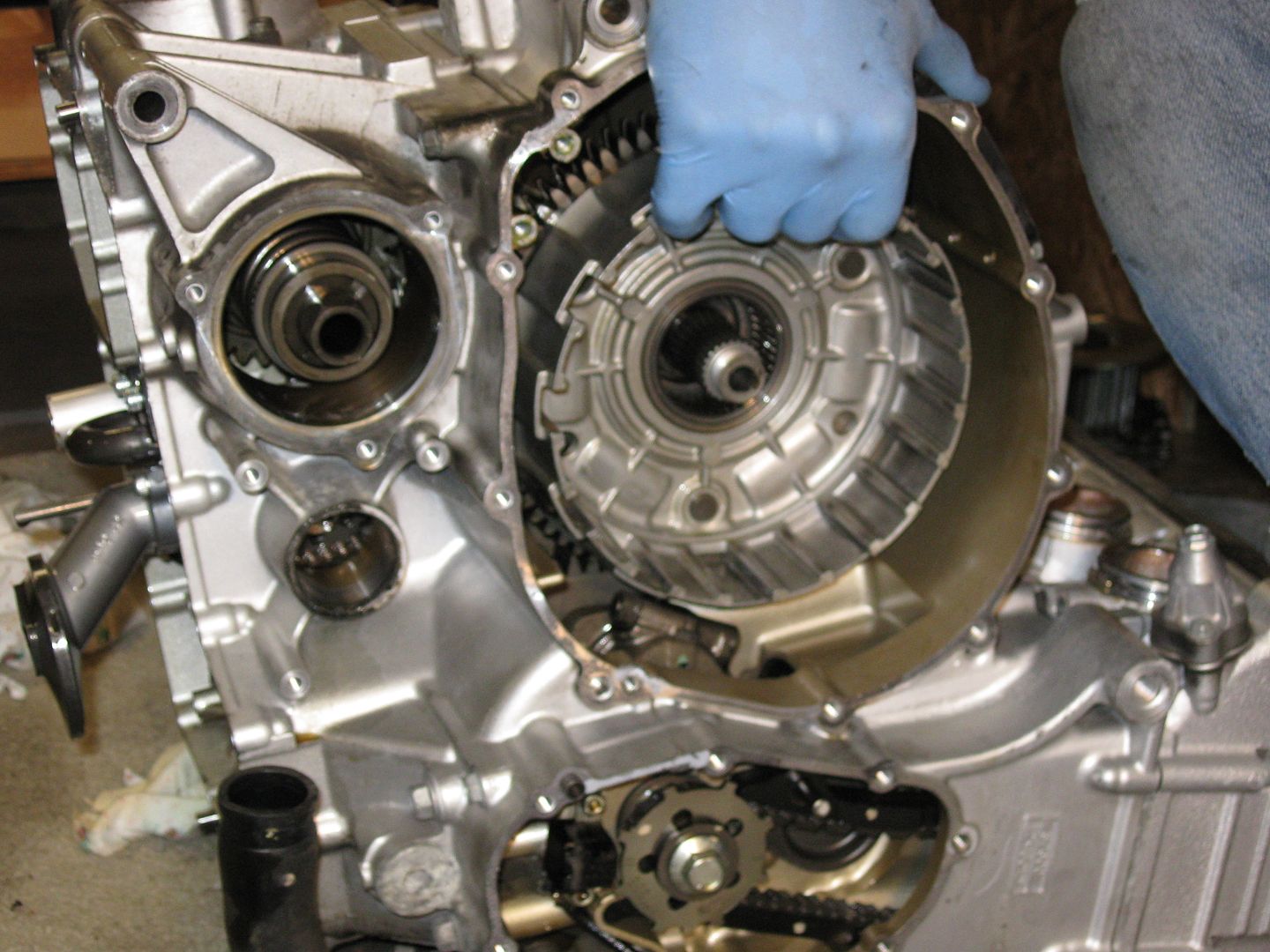

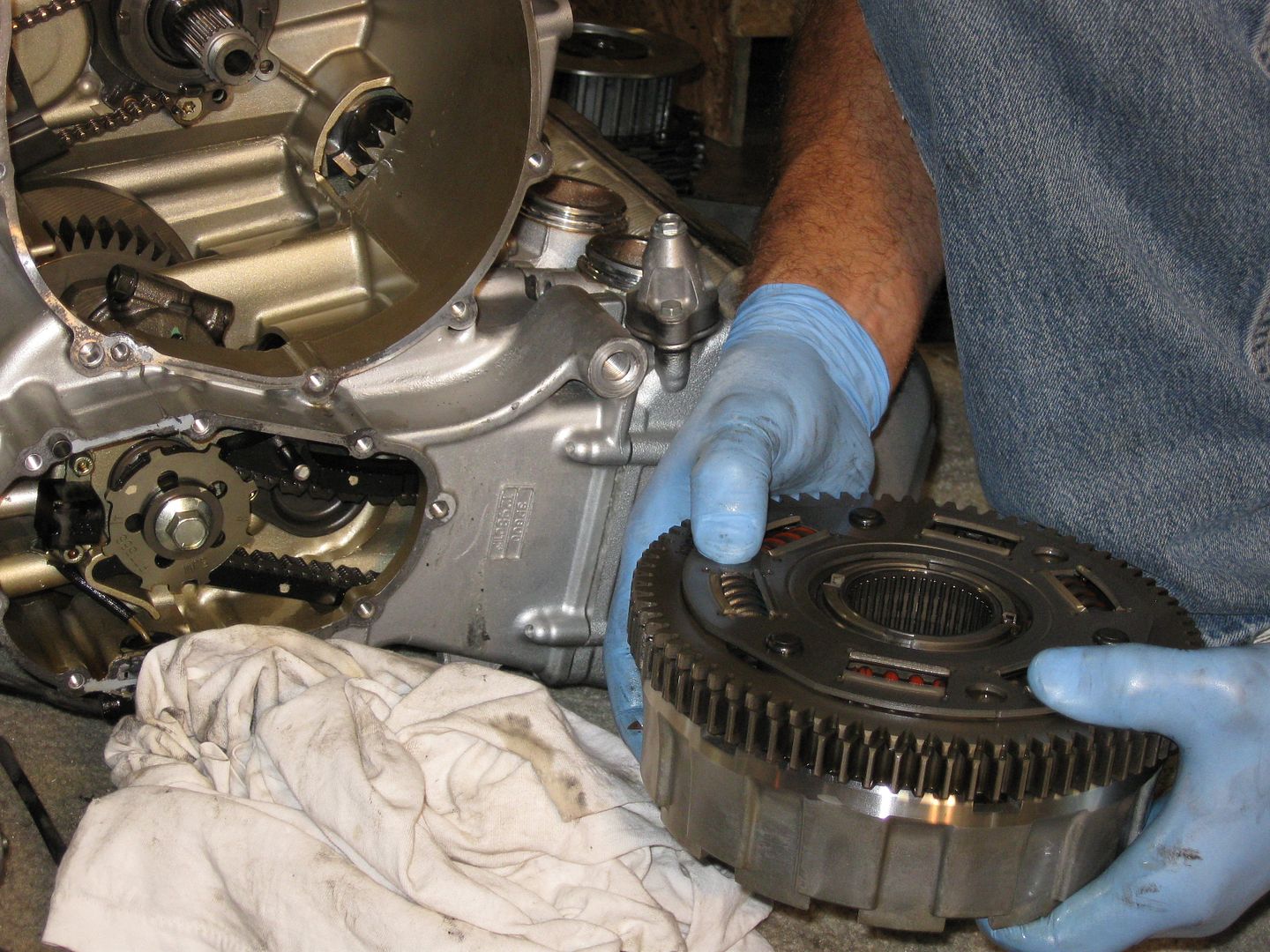

Now things get interesting and ..........