RossKean

Well-known member

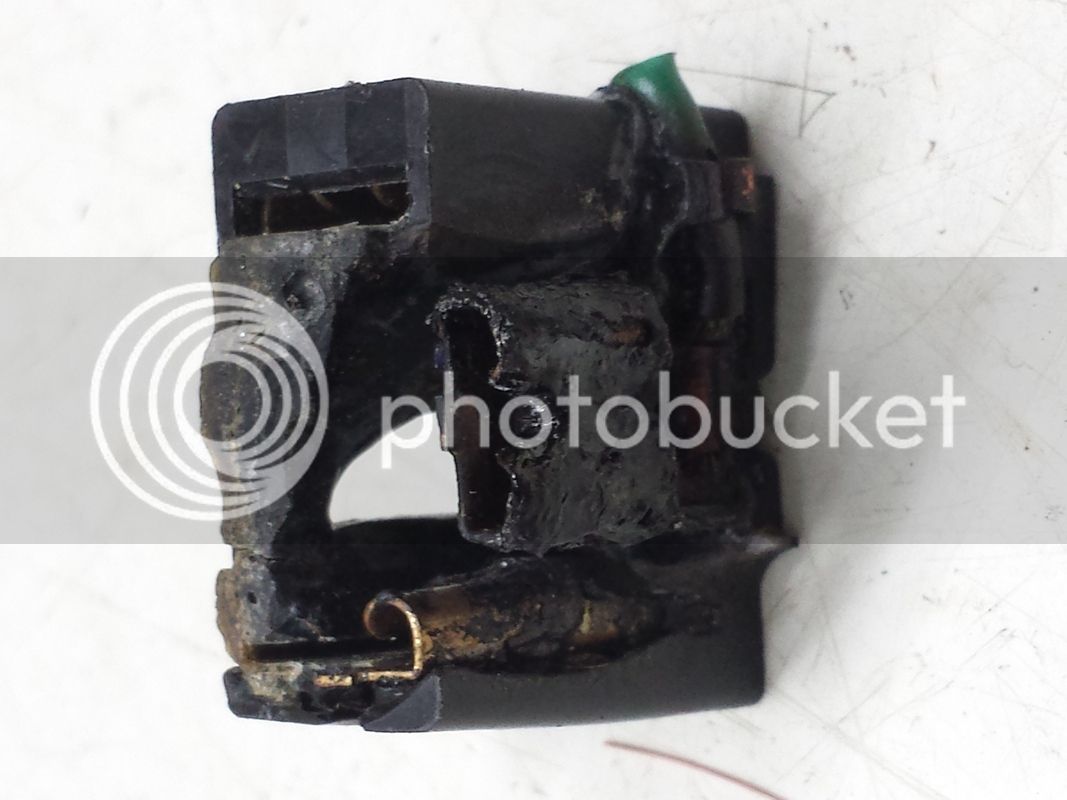

I changed both headlight bulbs about a month (and 10,000 miles) ago. I noticed, today, that my left headlight was out. Oh well, it was a cheap bulb so I just got another to replace it. It was a ***** getting the socket off the bulb and I noticed that the middle tab on the bulb looked burnt. Not good! So I looked at the socket and it is pretty much toasted. I am assuming that the bulb base overheated and cooked things.

Anyway, has this happened to anyone before and how did you fix it? Parts fiche only lists the complete sub-harness for $200+. I wonder if a standard H4 automotive socket is the same size as the Yamaha one? Obviously, the tabs line up with the H4 but I don't know about physical dimensions of the case. Do they come with wires to splice into the harness or are the wires crimped to the terminals? I am concerned that there may not be enough working room without pulling the nose off. I probably need to cut the wires back an inch or so since they are probably cooked and somewhat oxidized.

Crap!

Anyway, has this happened to anyone before and how did you fix it? Parts fiche only lists the complete sub-harness for $200+. I wonder if a standard H4 automotive socket is the same size as the Yamaha one? Obviously, the tabs line up with the H4 but I don't know about physical dimensions of the case. Do they come with wires to splice into the harness or are the wires crimped to the terminals? I am concerned that there may not be enough working room without pulling the nose off. I probably need to cut the wires back an inch or so since they are probably cooked and somewhat oxidized.

Crap!

Last edited by a moderator: