timk

timk

By chance were you using those high watt bulbs?

No, just a standard store-brand (cheap) H4. Possible that it was a defective bulb that had some additional resistance (=heat) in the internal connections in the base that started things but more likely just a weak connection at the socket. Quite a few miles on the bike and I'm not shy about riding in the rain. Sometimes, **** happens!By chance were you using those high watt bulbs?

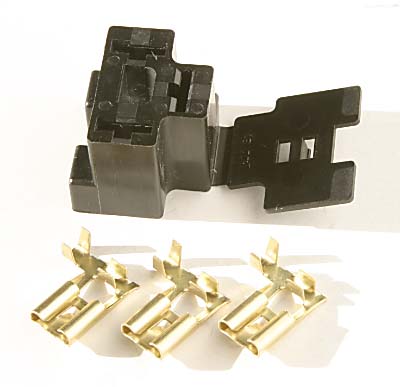

+1, you can't go wrong with the Eastern Beaver H4 Headlight Relay Kit, and your headlights will be brighter than you've ever seen them, since the EB H4 kit uses heavier gauge wiring and sources the power to the headlights via a relay directly from the battery so all the losses through the crappy thin OEM wiring (even if it is technically rated to take the load) are eliminated. I have used this kit on a few bikes before and was very pleased with the difference in brightness/performance.Eastern Beaver mark a real good bypass harness for the FJR.So long as the other H4 socket is good, ya good to go and it will reduce the load from the neutral spider connector circuit.

Just terminate the crook wiring on the burnt loom.

I would make an exception for the headlights harness and have them connect directly to the battery terminals.The FZ-1 has two separate current paths. One is for constant power and the other goes through the relay for switched power. Each circuit can handle up to 10A (120W). The total amperage used via the relay (switched power) should not exceed 30A (360W). The total amperage on the constant side should not exceed 30A (360W). The total amperage for the entire FZ-1 should not exceed 30A (360W).

Yeah, I did trim a couple of strands at the FZ-1 end but I did use the 10 ga.Check again that 10 ga. to the FZ1, as I recall from installing on a friend's bike, it will not accept 10 ga. It's likely 12 ga. or could be a 10 ga. with a couple of missing strands at the FZ1 end.......

A few years ago, I seriously considered HID replacements for the headlamps but was never happy with any of the Hi-beam solutions. Not to say they didn't work but heard about too many issues with solenoid-operated shields.This thread needs some controversy.

Get HID lights. They use just one plug to trigger the relay, only use 35 watts of power and are brighter and longer lasting.

The best H4 HID lights do not have Hi/Lo capability. They are fixed and therefore no solenoid or weird connectors. I use HID, with Clearwater Krista LED which go to full power when the highbeam is used whether the lights have a solenoid or not. Great low beam performance with clean cutoff, and the auxiliary lights do the high beam duty better than any headlight.A few years ago, I seriously considered HID replacements for the headlamps but was never happy with any of the Hi-beam solutions. Not to say they didn't work but heard about too many issues with solenoid-operated shields.This thread needs some controversy.

Get HID lights. They use just one plug to trigger the relay, only use 35 watts of power and are brighter and longer lasting.

I would forget the harness completely and go with LEDs if anyone comes up with a really good one. They have low current draw, low temperature and they are very long-lived (probably out-last the motorcycle). The best I have heard about are "almost as good" as halogens. Whiter and (arguably) brighter but beam pattern is not ideal. Most don't meet the mark when done as a side-by-side comparison with standard halogen bulbs. Also a little concerned about the cooling fans on most of these bulbs. I expect the LEDs will outlast the fans by a factor of five in the less-than-ideal environment of the nose of a motorcycle.

Seems to me that Twigg found some LEDs that made him happy and since he is a LD rider, I'm sure they get a lot of nighttime use. LEDs have come a LONG way in the past couple of years. Hopefully, someone will come up with something that works with reflector geometry designed for halogen incandescent bulbs. I may have to revisit some of the research I have done on them...