RadioHowie

I Miss Beemerdons!

There's been a lot of discussion about fast idles on FJRs the past few months, many of which I've participated in.

I've just finished removal of my 04's throttle bodies and disassembly of the fast idle mechanism to possibly clarify some issues that may be present.

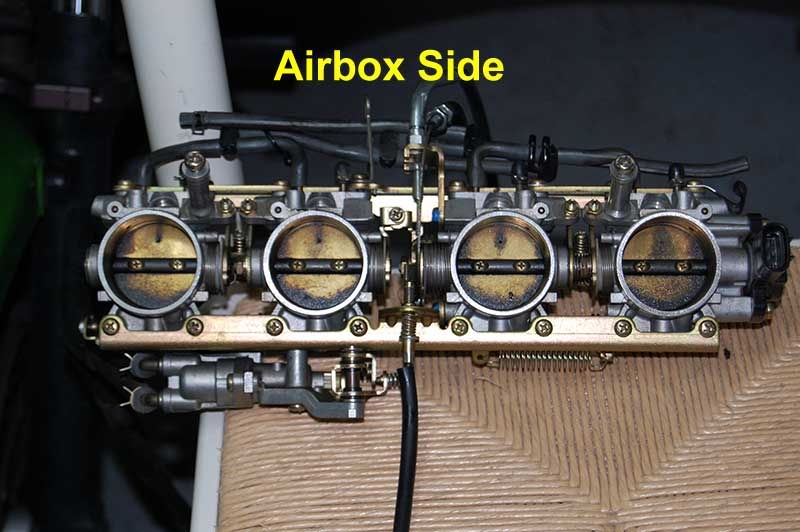

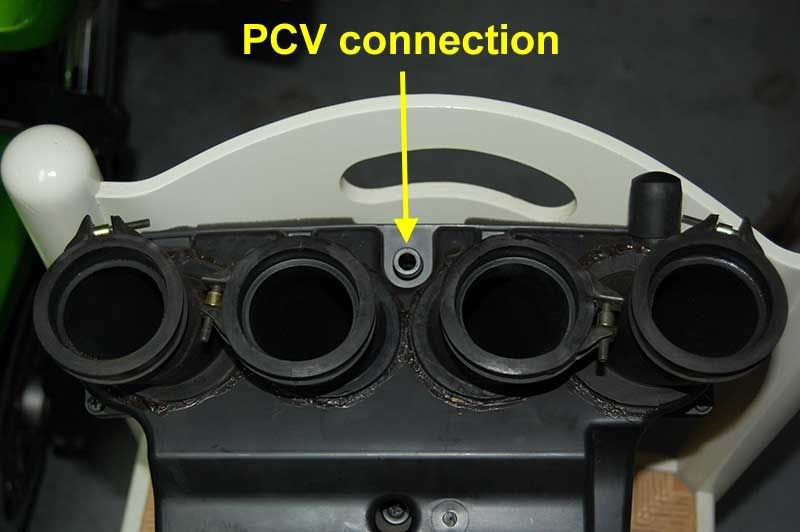

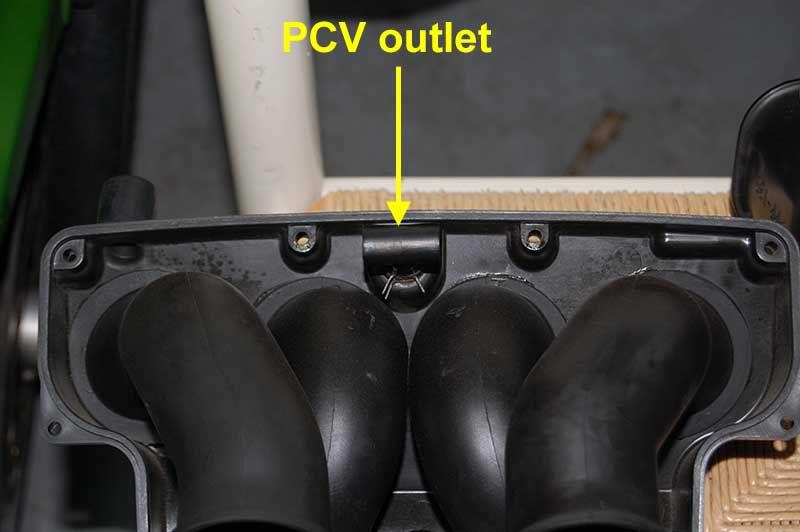

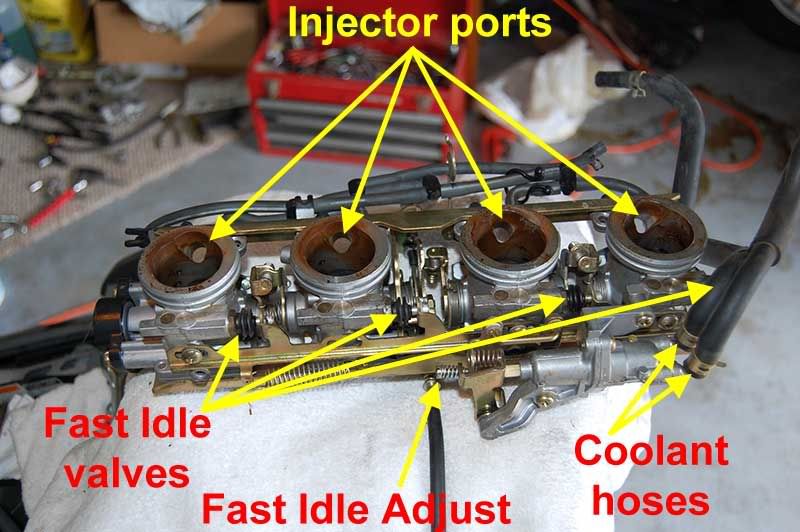

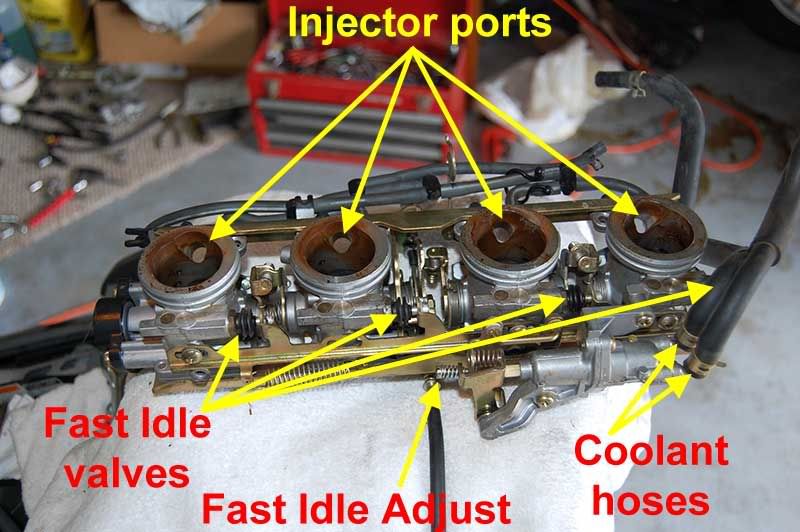

Here's the throttle bodies removed from the intake spigots, viewed from the motor side of the TBs. The Fast idle mechanism is clearly visible along with the two coolant hoses that run to the "wax motor" that controls movement of the assembly. For those just joining in on the discussion, when the motor is cold, there is a wax plug in the cylindrical area of the "wax motor" between what I've labeled "Fast Idle Adust" and "Coolant hoses." When the unit is cold and the wax has solidified, the entire assembly slides to the right (in this picture) pulling the fast idle valves OUT of the throttle bodies, allowing more air into the intake, effectively increasing the idle speed. It has been reported that Gen I motors' fast idles are in the 2000-2100rpm range, while Gen IIs typically run around 1500rpm. It is also speculated that 1500rpm may be too low, causing misfiring and "clunking" of Gen II motors when cold started.

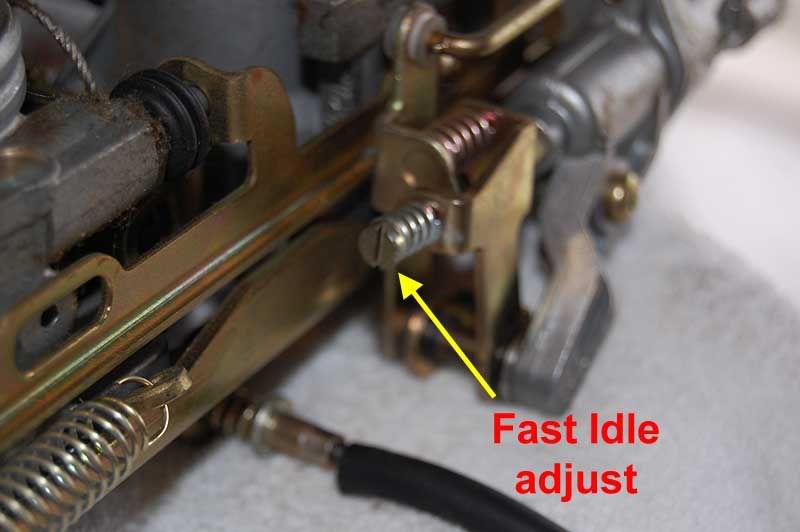

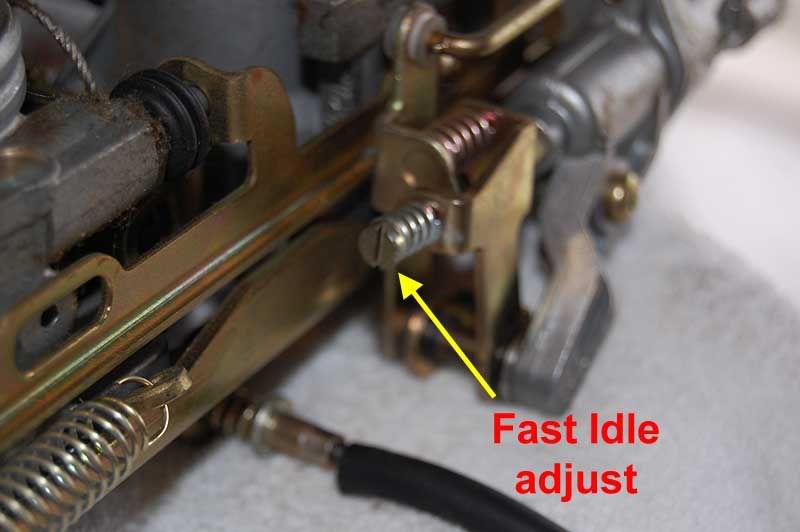

Here is a close-up of the adjusting screw on the fast idle mechanism.

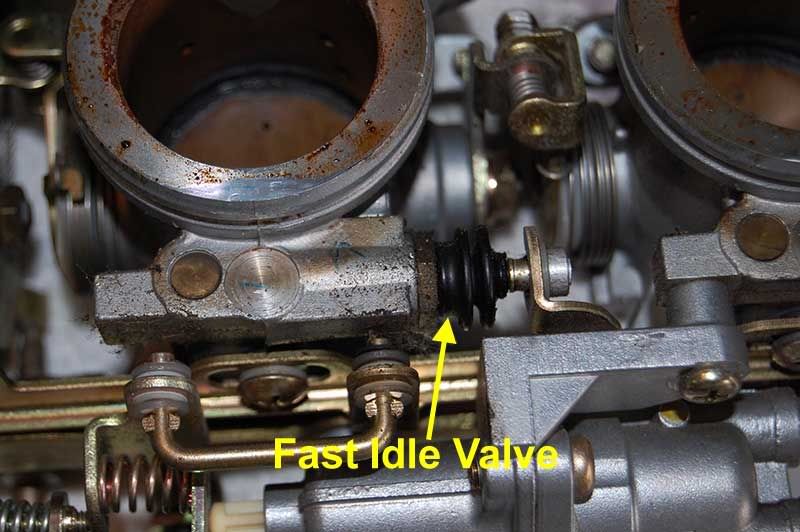

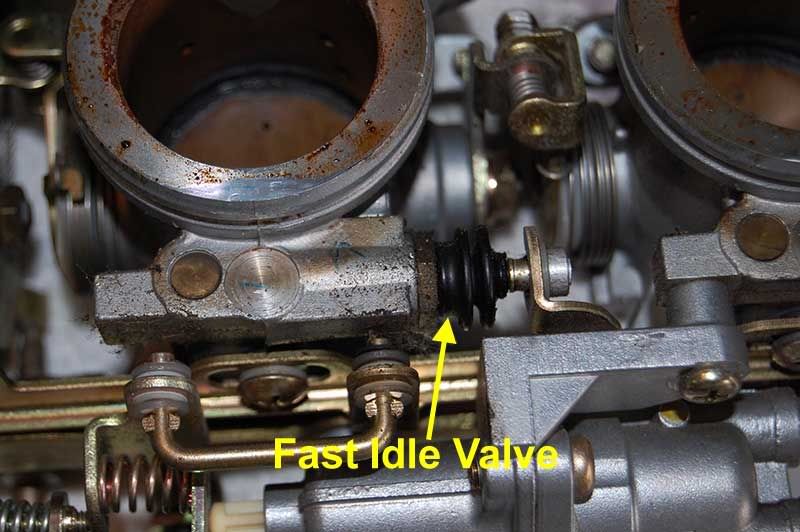

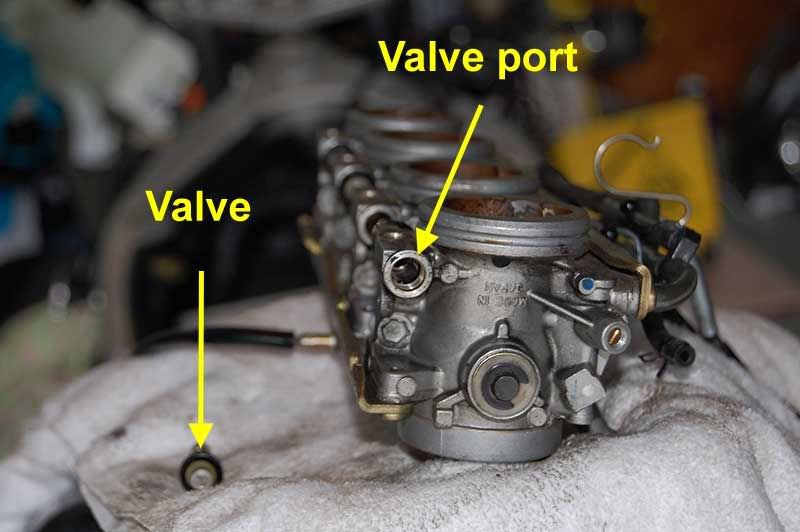

Closeups of two of the four fast idle valves mounted in the bottom of the throttle bodies.

As the motor warms up, hot coolant from the motor flows through the wax motor, melting the wax plug, and as the wax melts, it also expands with heat, forcing the entire fast idle assembly to slide to the left, allowing springs in the fast idle valves to seat, closing off the bypass ports which allow fast idle, thereby returning the idle to normal, which should be set statically at 1100rpm.

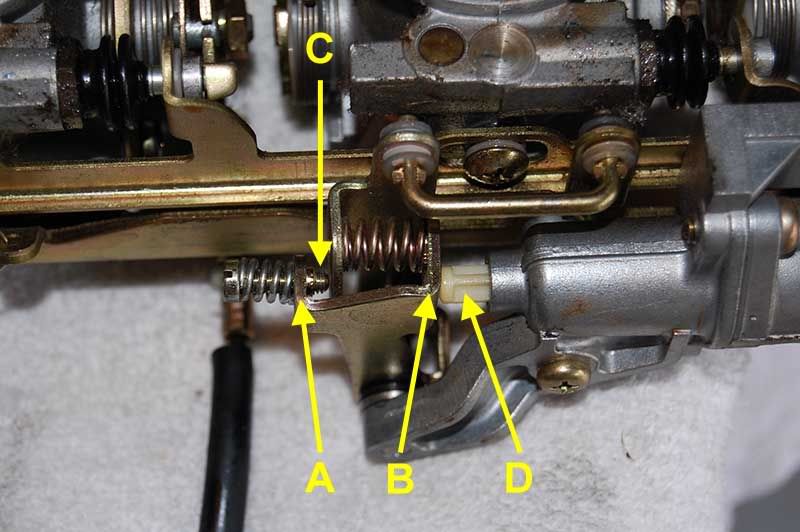

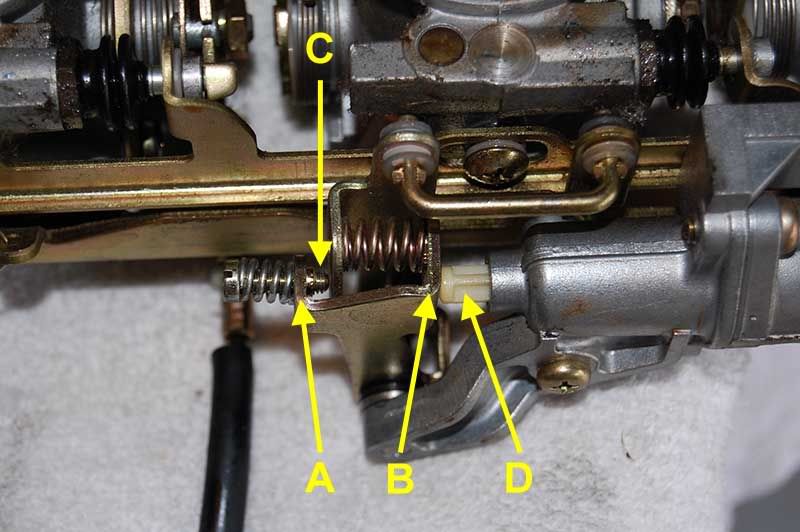

As noted above, may Gen IIs have been reported with fast idles of only 1500rpm, which may be too low for a consistent cold idle. In this picture, a close-up of the actual adjusting mechanism, you can see that the distance from the left of the adjusting screw bracket, A & B, to the side of the bracket that contacts the wax motor "piston", D is static in distance, but the adjusting screw contacts a second, spring loaded bracket at C, which is part of the sliding assembly that pulls the fast idle valves out to increase the idle speed. So screwing IN the fast idle adjusting screw moves the entire valve assembly to the right, increasing the fast idle speed by pulling the fast idle valves out further when cold.

As the motor warms, the wax plug melts, the liquid wax expands and pushes the entire fast idle assembly to the left (again in orientation with these pictures) and compression springs in the fast idle valves cause the valves to retract back into the throttle bodies, closing off the bypass ports, and reducing the idle to "normal".

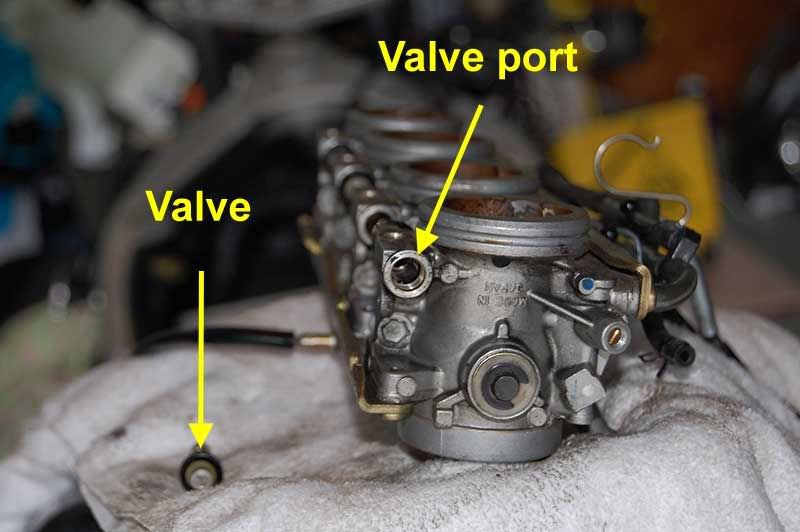

Here is TB #1 with the fast idle valve removed.

And here's a problem I found with my fast idle valves. This is a closeup of the valve from TB#1, by the rider's left knee.

All four were seriously gunked up with crud, so when the motor warms and the fast idle mechanism retracts, the valves are very hesitant to seat, i.e., return to "normal" idle position. Unfortunately, the valves are longer than the clearance between the throttle body castings, and therefore it's impossible to completely remove the fast idle valves from TBs #2, 3 & 4 without separating the TBs, a process I don't recommend. You can, though, loosen them from the TB castings with a 12mm wrench, pull them out about 75% of the way and soak the bores with suitable cleaner, manually work the valves in and out to clean out the bores.

My 04 has 46,000 miles on it and you can see the amount of crud on that one valve. All 4 are that dirty, so I would recommend TB removal and fast idle valve cleaning be added to your FJR's maintenance schedule at some point in its lifespan.

'Howie

Edit: BTW, don't know if increasing the fast idle to ~ 2k rpm is a good idea for AE models. Will the bike atttempt to engage the clutch if the bike's in gear at this rpm???

I've just finished removal of my 04's throttle bodies and disassembly of the fast idle mechanism to possibly clarify some issues that may be present.

Here's the throttle bodies removed from the intake spigots, viewed from the motor side of the TBs. The Fast idle mechanism is clearly visible along with the two coolant hoses that run to the "wax motor" that controls movement of the assembly. For those just joining in on the discussion, when the motor is cold, there is a wax plug in the cylindrical area of the "wax motor" between what I've labeled "Fast Idle Adust" and "Coolant hoses." When the unit is cold and the wax has solidified, the entire assembly slides to the right (in this picture) pulling the fast idle valves OUT of the throttle bodies, allowing more air into the intake, effectively increasing the idle speed. It has been reported that Gen I motors' fast idles are in the 2000-2100rpm range, while Gen IIs typically run around 1500rpm. It is also speculated that 1500rpm may be too low, causing misfiring and "clunking" of Gen II motors when cold started.

Here is a close-up of the adjusting screw on the fast idle mechanism.

Closeups of two of the four fast idle valves mounted in the bottom of the throttle bodies.

As the motor warms up, hot coolant from the motor flows through the wax motor, melting the wax plug, and as the wax melts, it also expands with heat, forcing the entire fast idle assembly to slide to the left, allowing springs in the fast idle valves to seat, closing off the bypass ports which allow fast idle, thereby returning the idle to normal, which should be set statically at 1100rpm.

As noted above, may Gen IIs have been reported with fast idles of only 1500rpm, which may be too low for a consistent cold idle. In this picture, a close-up of the actual adjusting mechanism, you can see that the distance from the left of the adjusting screw bracket, A & B, to the side of the bracket that contacts the wax motor "piston", D is static in distance, but the adjusting screw contacts a second, spring loaded bracket at C, which is part of the sliding assembly that pulls the fast idle valves out to increase the idle speed. So screwing IN the fast idle adjusting screw moves the entire valve assembly to the right, increasing the fast idle speed by pulling the fast idle valves out further when cold.

As the motor warms, the wax plug melts, the liquid wax expands and pushes the entire fast idle assembly to the left (again in orientation with these pictures) and compression springs in the fast idle valves cause the valves to retract back into the throttle bodies, closing off the bypass ports, and reducing the idle to "normal".

Here is TB #1 with the fast idle valve removed.

And here's a problem I found with my fast idle valves. This is a closeup of the valve from TB#1, by the rider's left knee.

All four were seriously gunked up with crud, so when the motor warms and the fast idle mechanism retracts, the valves are very hesitant to seat, i.e., return to "normal" idle position. Unfortunately, the valves are longer than the clearance between the throttle body castings, and therefore it's impossible to completely remove the fast idle valves from TBs #2, 3 & 4 without separating the TBs, a process I don't recommend. You can, though, loosen them from the TB castings with a 12mm wrench, pull them out about 75% of the way and soak the bores with suitable cleaner, manually work the valves in and out to clean out the bores.

My 04 has 46,000 miles on it and you can see the amount of crud on that one valve. All 4 are that dirty, so I would recommend TB removal and fast idle valve cleaning be added to your FJR's maintenance schedule at some point in its lifespan.

'Howie

Edit: BTW, don't know if increasing the fast idle to ~ 2k rpm is a good idea for AE models. Will the bike atttempt to engage the clutch if the bike's in gear at this rpm???

Last edited by a moderator: