When I get to the house later, I'll pull up my engine replacement pictures to show you where all the motor mounts are.

Also, VERY important to remember, if the torque spec is 35 lbs, that means the bolt will strip the engine block at 36. Don't ask me how I know.

That is a thought which scares me because when I installed the Motovation sliders (no cut) - the instructions said to torque those 4 bolts to 40 lb-ft. These were only supposed to go 35 max weren't they? I hope I didn't strip anything, will loosen them up again and follow the pictures and instructions from you about the engine mounting bolts and their torques when I get home this evening. :blink:

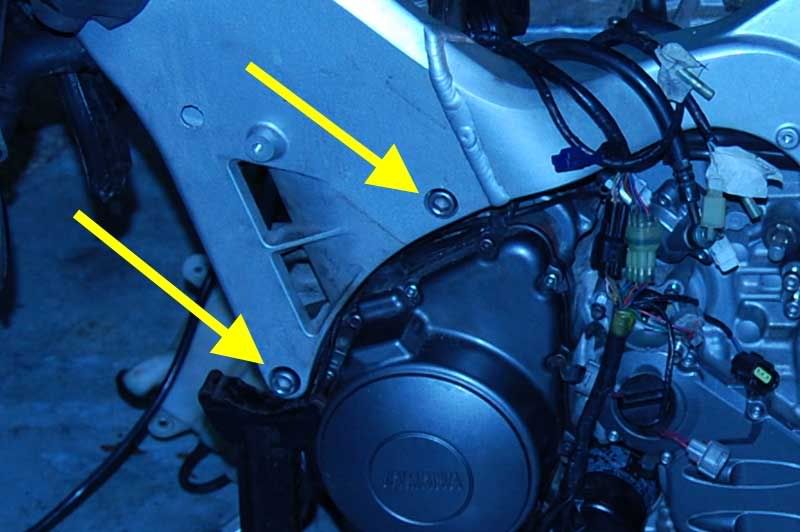

Okay, puppychow...you know about 4 of the motor mounts...two on each side of the bike on the frame spars (left side shown)

There's one at the bottom back of the motor (right side shown just above foot peg)

One at the top back of the motor, a long bolt that goes all the way from outside left to outside right (left side shown just above foot peg, just below the final motor mount shown in Pic #6)

Two on top of the motor (underneath the throttle bodies)

and last but not least one just below the shift arm, the triangular looking bracket with two small hex head bolts on the left, one large on the right.

There is a "correct" tightening sequence involving the four long hex-head bolts that go through the frame spars...

You would first loosen the pinch bolts locating the spacers the bolts pass through on the right side. When they are loose, you torque down the two bolts on the LEFT side first, then torque down the two bolts on the spacers on the RIGHT side,

THEN tighten the pinch bolts to spec.

What this does is lets the left side bolts pull the motor tight to the left frame spar. Then the bolts on the right side have been torqued to the spacers and finally, the pinch bolts on the spacers are tightened. Done this way, you guarantee that the motor is tight in the frame, up against the left side.

You'll notice in Pic#2, the bottom/rear motor mount, also passes through a spacer that is held in place by pinch bolts. The same sequence is done here....i.e., loosen the pinch bolts, torque the bolt into the motor to spec, then tighten the pinch bolts.

The top/rear motor mount is basically just a long bolt that goes through the frame and bolts from the outside. The motor basically just "hangs" from this bolt, so there is no spacer/pinch setup.

So the correct tightening sequence, assuming ALL the motor mounts are loose, would be:

1: Torque left side frame spar bolts.

2: With pinch bolts loose on right frame spar, torque right side bolts to the motor through the spacers,

3: With the pinch bolts loose on the bottom/rear mount, torque the bolt to the motor through the spacers,

4: Torque down the pinch bolts on the frame spar spacers and bottom;rear spacer,

5. Torque down the top motor mounts to the frame first, then the mount to the motor (picture #5)

6: Torque to spec the small, triangular mount just below the upper shift arm, just right of the shift rod that runs from the foot shift to the shift arm.

Hope this helps.