JamesK

Got to ride

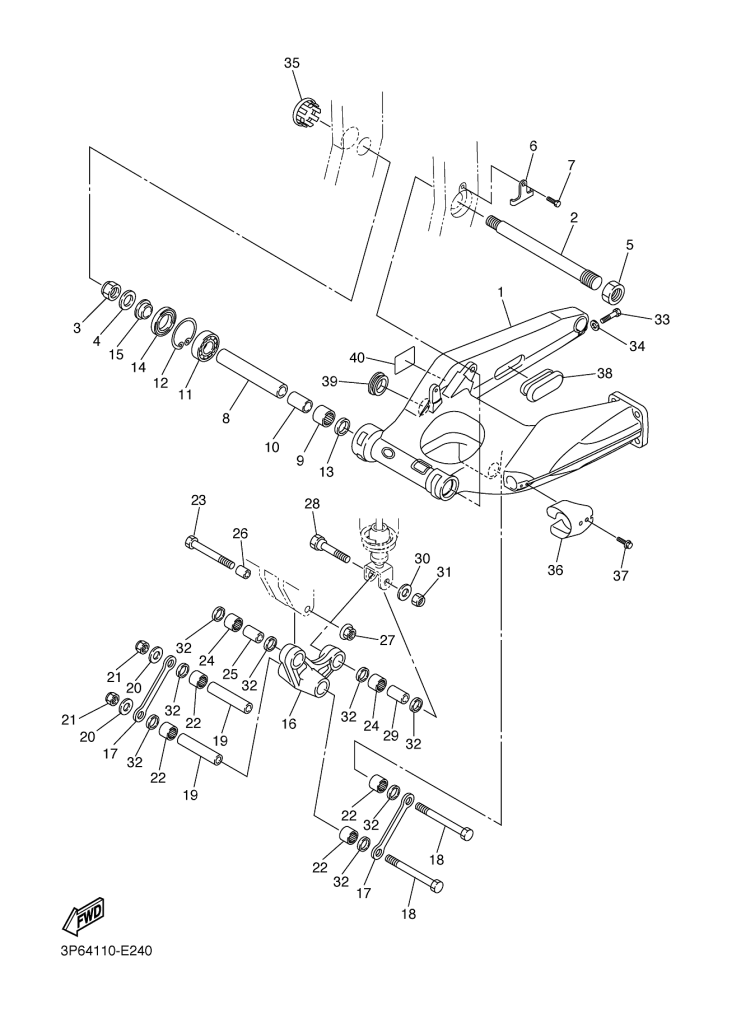

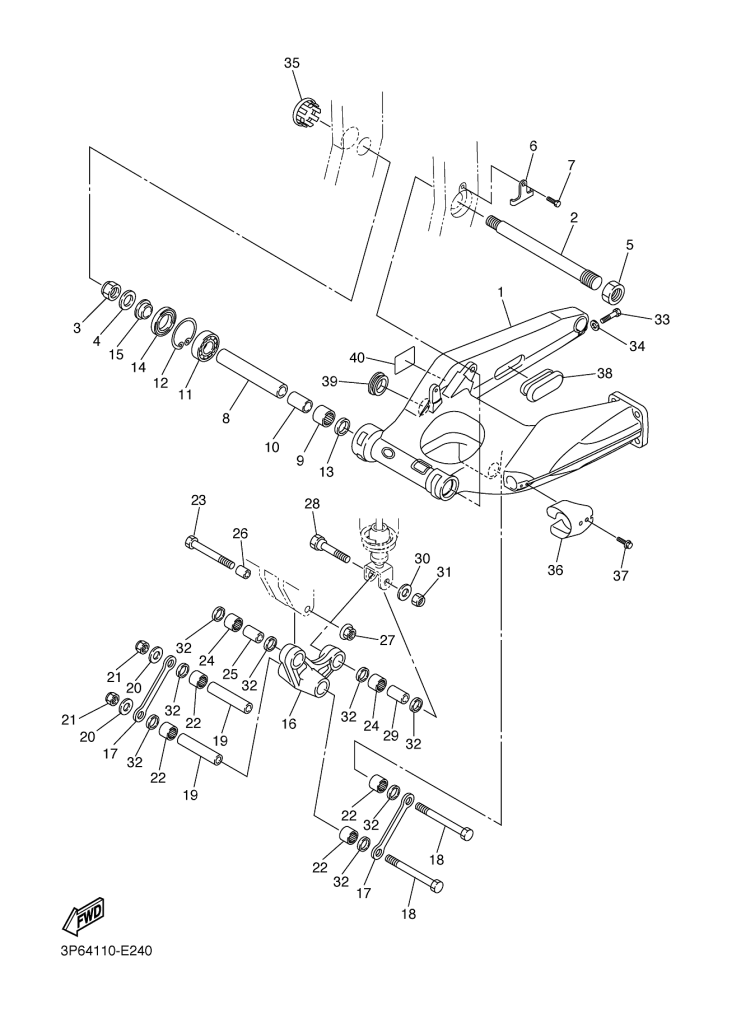

The bottom race and bearings (#19 in the diagram below) on my Relay Arm were tight, almost seized up, so when I pulled it apart I found that some of the roller bearings had broken into smaller pieces. I also found pitting marks/galling on the collar (#19). It appears that some water/moisture got inside this joint; it was not totally dry of grease but did have some corrosion... All the linkages appeared ok and moved freely and smoothly about 40k miles ago when I installed the rebuilt rear Penske shock.

At 115k miles I don't mind replacing all the bearings, seals and collars in the Relay Arm, even though only the lower one (middle) is badly pitted/galled, with the front collar (where the bottom of the rear shock connects) is discolored but does not show obvious galling. The top collar (that mounts to the swing arm and requires the R/R of the center stand) is moving freely but has a lot of play in it. I am not sure if this means I just need new roller bearings, collars and seals or if there is actually some kind of wear in the Relay Arm innards.

I have already ordered replacements of the bearings, collars and oil seals as shown on the fiche on RonAyers.com

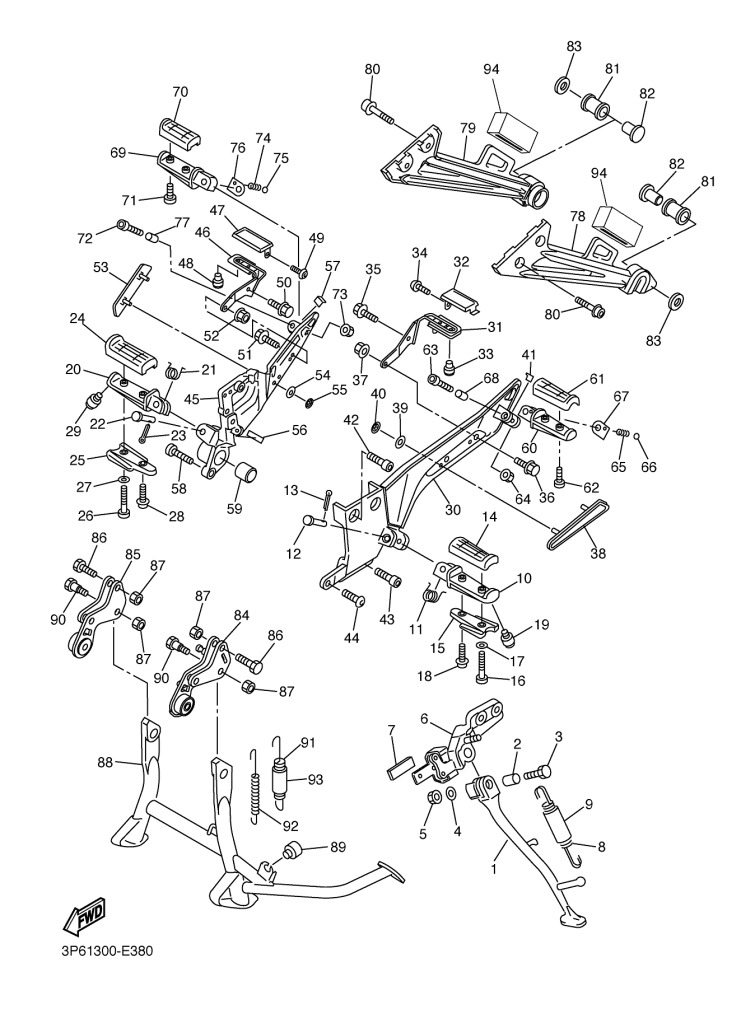

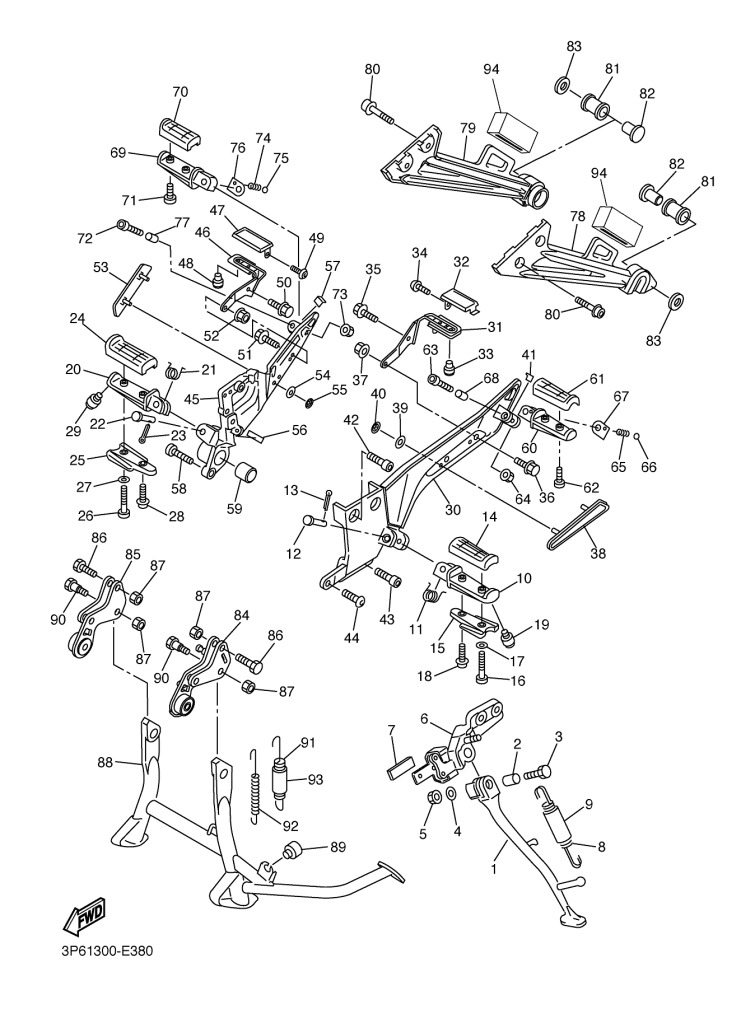

I am trying to remove the Relay Arm since I'll need to have it on the bench to clean up and install the bearings and seals. Unfortunately I seem to be running into problems getting the Relay Arm off. I've removed the center stand (because the top Relay Arm bolt (#23) will not come out with the center stand brackets (#84 & 85) in place) however, I still can't get the center stand brackets off because the top bolts on each side hit the header pipes.

Do you really need to drop the headers in order to just be able to remove the Relay Arm :blink:

The only reference I've been able to find in my search is this Relay Arm Link, but it does not mention the bits that need to be removed. The FSM for this job does not show/include the exhaust assembly so there is no mention of having to drop the headers, just to be able to get the bolts of the center stand brackets (#84 & 85) off, which in turn will enable you to get the top Relay Arm bolt out.

I am also wondering if these two top center stand bracket bolts (#86) can be reinserted with the bolt heads facing inwards to make the removal in the future less of a PITA, since these seem to be just "straight" bolts with nothing that would interfere if they were reversed.

Another question for the folks who have done this job or know what the inside (where the roller bearings sit) of the Relay Arm looks like. The bottom/middle part (where the #19 collar goes) seems to have different surfaces b/w the LHS and RHS sides. When sitting on the bike, the LHS inner surface is smooth, where as the RHS inner surface has distinct recesses where each roller bearing sits in. Should these not be identical since the roller bearings that sit in them are the same?

I would really appreciate any advice/help on my questions.

At 115k miles I don't mind replacing all the bearings, seals and collars in the Relay Arm, even though only the lower one (middle) is badly pitted/galled, with the front collar (where the bottom of the rear shock connects) is discolored but does not show obvious galling. The top collar (that mounts to the swing arm and requires the R/R of the center stand) is moving freely but has a lot of play in it. I am not sure if this means I just need new roller bearings, collars and seals or if there is actually some kind of wear in the Relay Arm innards.

I have already ordered replacements of the bearings, collars and oil seals as shown on the fiche on RonAyers.com

I am trying to remove the Relay Arm since I'll need to have it on the bench to clean up and install the bearings and seals. Unfortunately I seem to be running into problems getting the Relay Arm off. I've removed the center stand (because the top Relay Arm bolt (#23) will not come out with the center stand brackets (#84 & 85) in place) however, I still can't get the center stand brackets off because the top bolts on each side hit the header pipes.

Do you really need to drop the headers in order to just be able to remove the Relay Arm :blink:

The only reference I've been able to find in my search is this Relay Arm Link, but it does not mention the bits that need to be removed. The FSM for this job does not show/include the exhaust assembly so there is no mention of having to drop the headers, just to be able to get the bolts of the center stand brackets (#84 & 85) off, which in turn will enable you to get the top Relay Arm bolt out.

I am also wondering if these two top center stand bracket bolts (#86) can be reinserted with the bolt heads facing inwards to make the removal in the future less of a PITA, since these seem to be just "straight" bolts with nothing that would interfere if they were reversed.

Another question for the folks who have done this job or know what the inside (where the roller bearings sit) of the Relay Arm looks like. The bottom/middle part (where the #19 collar goes) seems to have different surfaces b/w the LHS and RHS sides. When sitting on the bike, the LHS inner surface is smooth, where as the RHS inner surface has distinct recesses where each roller bearing sits in. Should these not be identical since the roller bearings that sit in them are the same?

I would really appreciate any advice/help on my questions.

Last edited by a moderator: