FrankD

Well-known member

Update as of 8 PM....

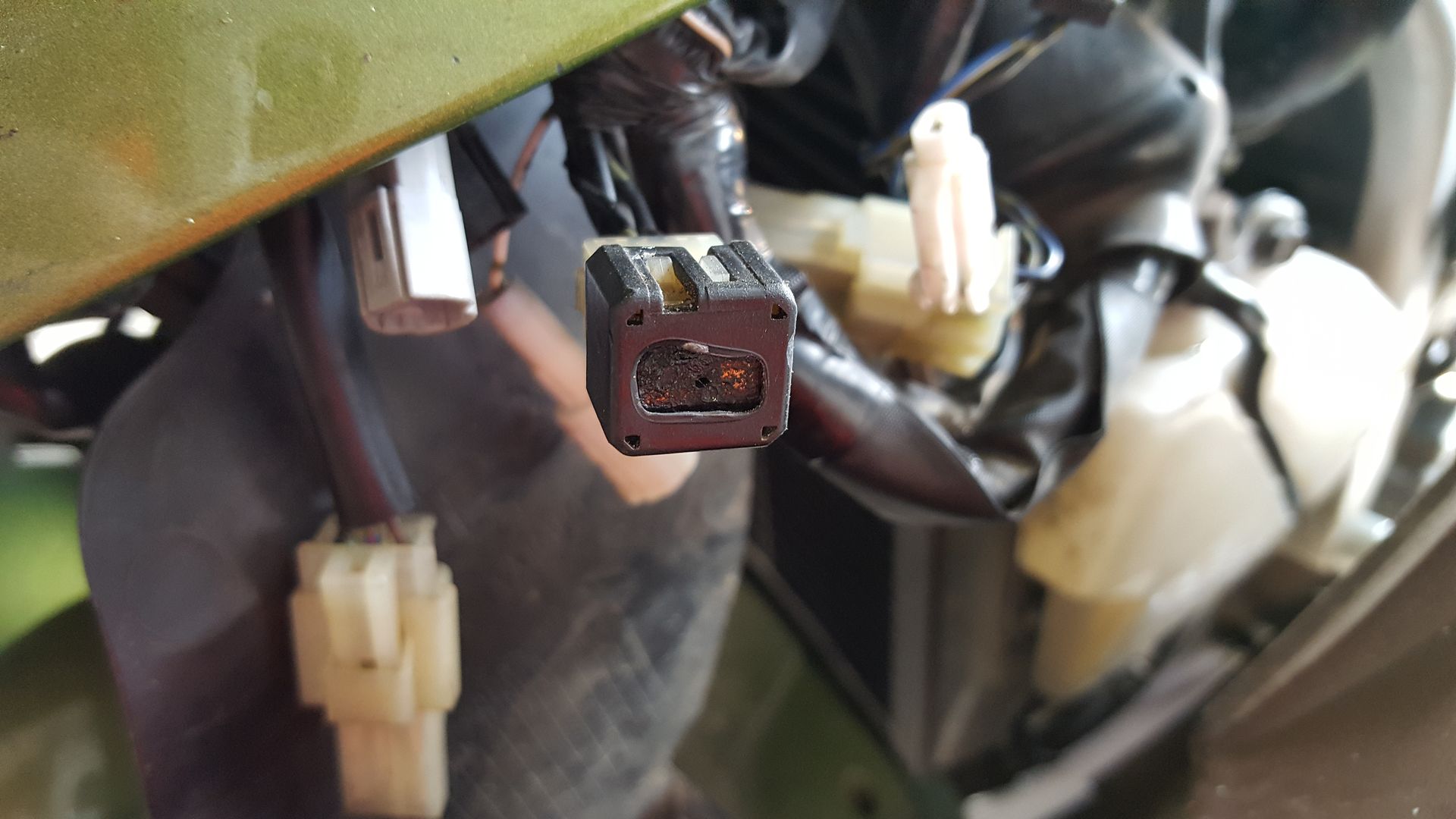

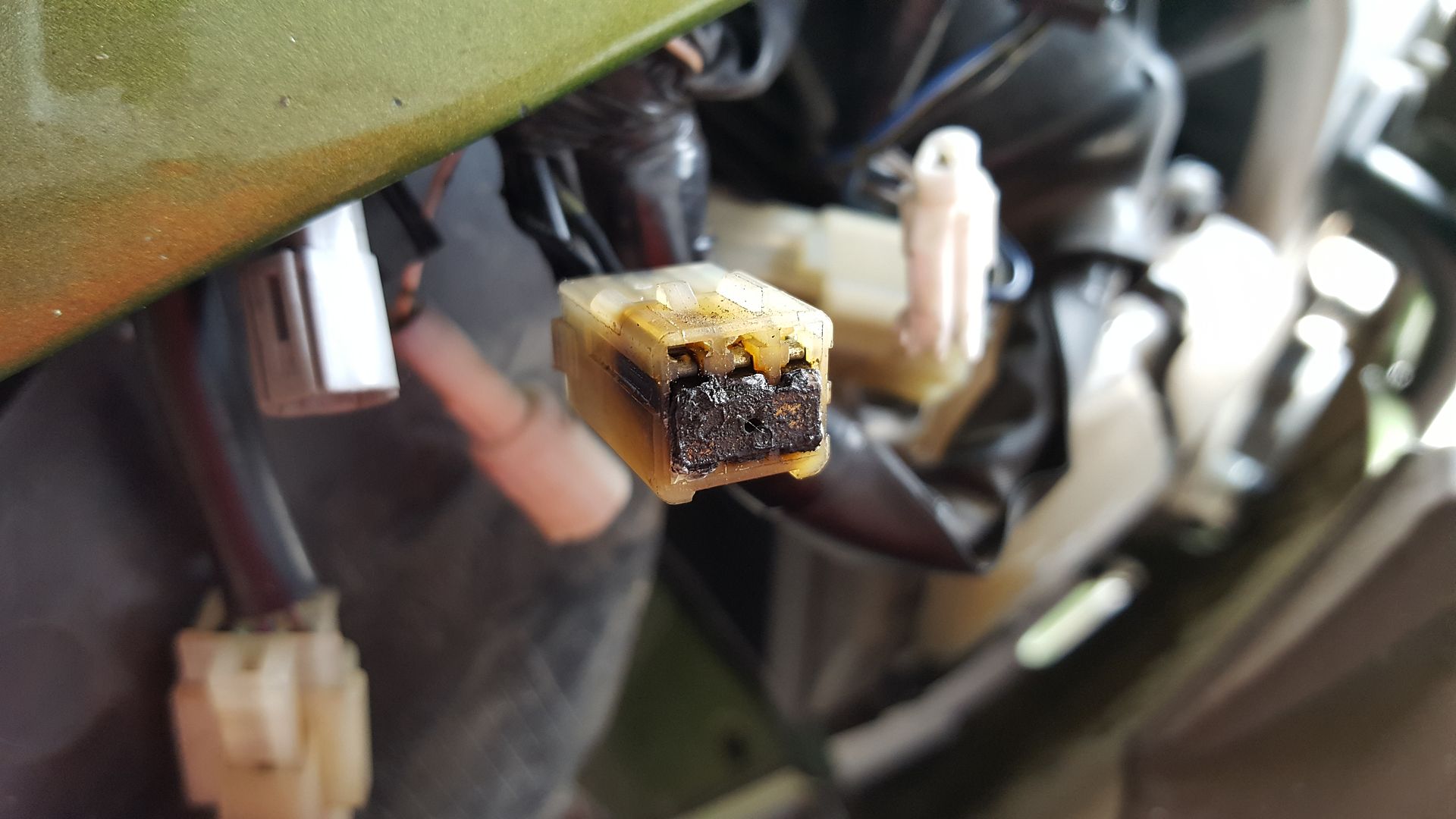

Checked with Yamaha and confirmed that the S4 recall had been performed. Also verified that the windscreen, horn & glove box solenoids were nonfunctional. Followed the wiring diagram linked above to the S6 spider as the likely culprit. I pulled of enough of the bodywork to give me access to the S6 spider and took a looksy. Wasn't as horrible as I expected. The terminal for the main ground wire (thickest of the bunch) was corroded and the shunt was corroded as well. I decided not to take the path of soldering the wires together, primarily because I haven't grown the avocados yet to perform an irreversible "repair". Instead, I opted for a thorough cleaning of the terminals and the shunt and then a liberal application of contact grease to the terminals, the shunt and the inside of the terminal cap. I gave it a handful of starts and a 30 minute ride and the problem seems to be gone. Will confirm over the next few days - it's my daily transportation.

At the next major tear-down, I plan on doing the same with the rest of the spiders. If the problem recurs after that, I'll consider more drastic harness modifications (dikes & solder type).

Thx to all & cheers.

Checked with Yamaha and confirmed that the S4 recall had been performed. Also verified that the windscreen, horn & glove box solenoids were nonfunctional. Followed the wiring diagram linked above to the S6 spider as the likely culprit. I pulled of enough of the bodywork to give me access to the S6 spider and took a looksy. Wasn't as horrible as I expected. The terminal for the main ground wire (thickest of the bunch) was corroded and the shunt was corroded as well. I decided not to take the path of soldering the wires together, primarily because I haven't grown the avocados yet to perform an irreversible "repair". Instead, I opted for a thorough cleaning of the terminals and the shunt and then a liberal application of contact grease to the terminals, the shunt and the inside of the terminal cap. I gave it a handful of starts and a 30 minute ride and the problem seems to be gone. Will confirm over the next few days - it's my daily transportation.

At the next major tear-down, I plan on doing the same with the rest of the spiders. If the problem recurs after that, I'll consider more drastic harness modifications (dikes & solder type).

Thx to all & cheers.