I believe PPM is used with the tach signal as well, especially if the tach is the only speed signal. The lower PPM setting should move the acceptable speed range up, i.e. sets at faster speeds, may not set at a low speed you're used to using.

The more I read the questions, though, the more I'm convinced he's got vacuum crosstalk between cylinders.

In an automotive application you would find a common plenum in the intake manifold, behind the throttle plate and ahead of the intake valves. The plenum will be a good vacuum source for whatever you want to put on the car.

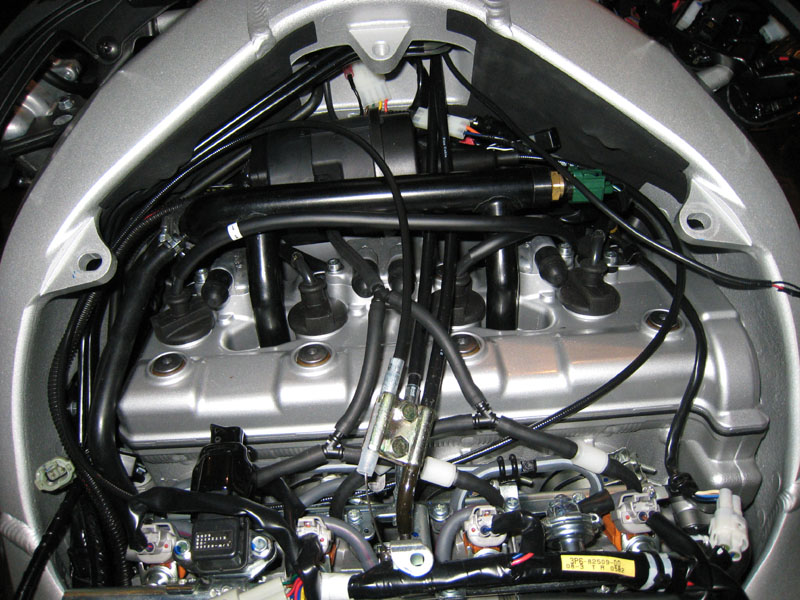

No such space exists on the bike, though. You have four completely independant intake systems, each pulling vacuum on the intake stroke, but ONLY the intake stroke. The vacuum is not constant at that port, which is why manometers need a restrictor in the vacuum tube: without the restrictor to reduce flow, you just get a vibrating column of fluid. If you tap all four vacuum ports without restricting the vacuum direction, you basically have just connected all the vacuuum ports to each other, and they pull from each other rather than the device you're trying to apply vacuum to. You've made the intake system non-independant, and they bleed vacuum to each other.

Get the check valves, see how it goes. Resistance is futile.

And as pointed out, it's usually good enough to tap one port only and use a reservoir, with a check valve between the reservoir and the vacuum source.