dcarver

Well-known member

What are the pro's and cons of each option, flush vs. filler neck?I have two JAZ flush mount caps to use up.Thought you were putting a filler neck on it???Go with the latter.

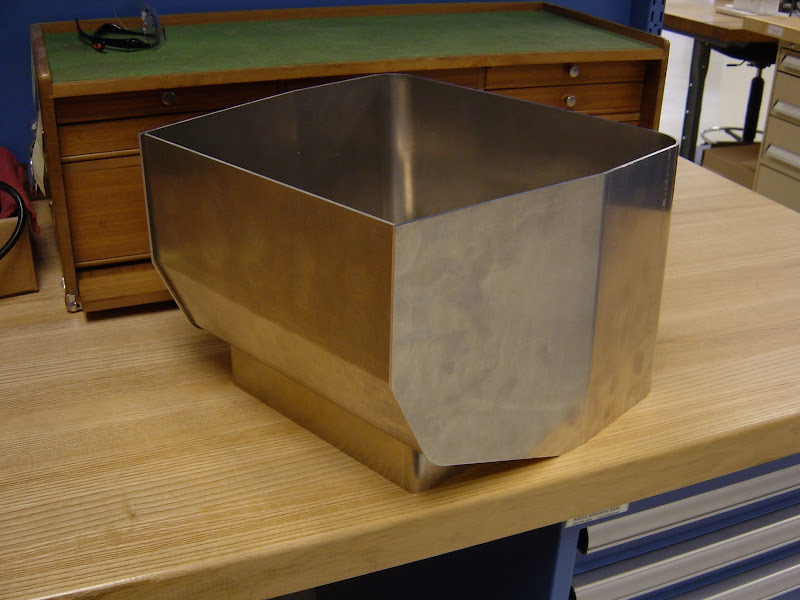

I would go with the latter, but I'm not positive the plate will stay flat with a hole in the corner. Since I'm cutting the hole before welding, and since the gasket will work better if it's up against a flat surface, I'm leaning toward putting it in the middle.

You know what? Now that I think about it, one of those flush mount caps is for my plastic tank. I could put a filler neck on one of these and a flush mount cap on the other.

Hhhmmm.

Glad I asked! I have them clamped together in the mill right now.

I owe you a beer Jeff!

I'll take a stab at it

Filler cap PRO's

Can stick nozzle in neck while lighting cigeratte with free hand.

Makes a good place to connect a bungie cord.

CON's

Sticks out like a sore thumb, disrupting visually clean lines?

It can catch your crotch in case of accidental get off neutring your male gender

Flush PRO

Can stack luggage on tank top

Looks cool

If one wanted to, could add Givi mounting **** to tank top then use Givi or other box for small storage (maps, gloves, flares, etc)

Flush CON

No place for bungee cords

Easier to overfill tank and make a mess

I'm sure interested to hear what some of the true LD Riders think about these pros' and con's..

Warchild?

Iggie?

Skoot?